A slider type linear displacement sensor

A linear displacement, slider type technology, applied in the field of displacement sensors, can solve the problems of large linearity error and distortion, and achieve the effect of offsetting excessive linearity error and distortion, improving anti-deformation ability and improving assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

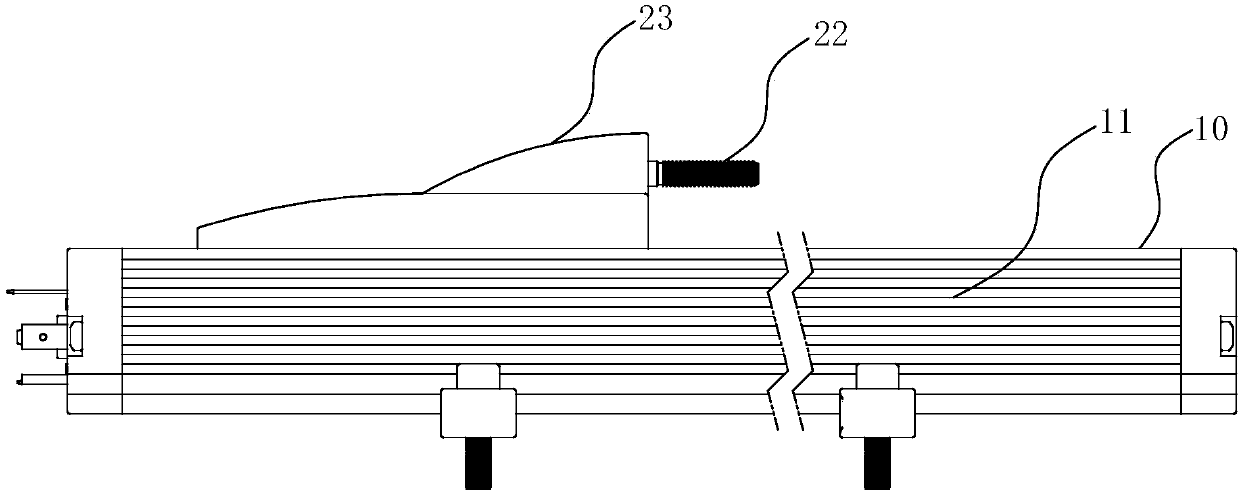

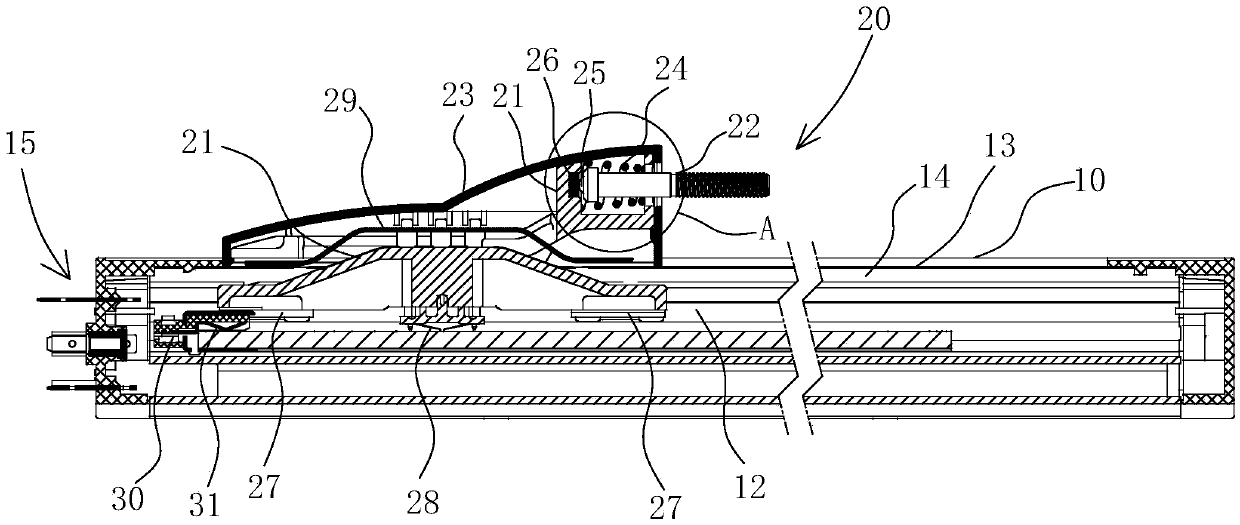

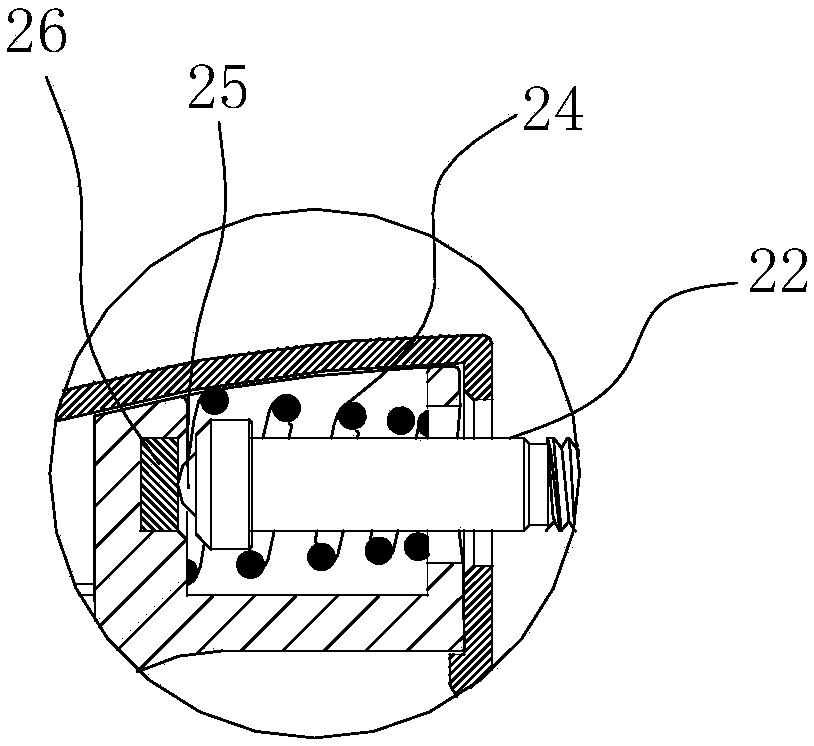

[0032] Now illustrate structural features of the present invention in conjunction with accompanying drawing:

[0033] The present invention includes a casing 10 and a slider brush assembly 20. The side casings located in the length direction of the casing 10 and arranged oppositely are composed of a corrugated plate body 11, and the outer surface of the corrugated plate body 11 is perpendicular to the casing 10. The section in the longitudinal direction is wave-shaped, and the housing 10 is provided with a guide groove 12 on the wave-shaped plate body 11 for the slider brush assembly 20 to move along the length direction of the housing 10 . The casing 10 is made of aluminum alloy, and the surface is plated with a layer of anodized aluminum, so as to prevent the casing of the product from being corroded and improve the service life of the product. In the present invention, the side casing of the casing 10 is creatively arranged in a corrugated structure, that is, the side panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com