Environment-friendly energy-saving type chain-grate boiler

A chain boiler and energy-saving technology, which is applied in the field of coal-fired boilers, can solve problems such as excess oxygen, increased oxygen input, and large environmental pollution, and achieve the effects of reducing emissions, saving energy, and improving combustion and emission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

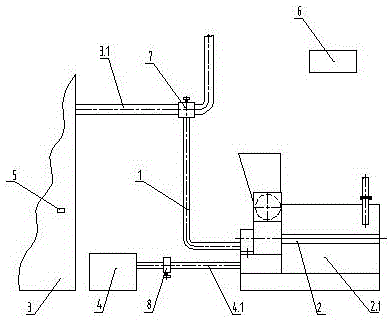

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

[0014] The environmentally friendly and energy-saving chain boiler shown in the accompanying drawings includes a pulverized coal grinder 2, a chain boiler 3, and an electrical control component 6; The pulverizer 2 inputs air; the chain boiler 3 is provided with an exhaust gas output pipe 3.1; the exhaust gas output pipe 3.1 and the pulverized coal grinder 2 are provided with an exhaust gas recycling pipe 1; one end of the air intake pipe 4.1 is connected to the side wall of the exhaust gas output pipe 3.1 It communicates with the exhaust gas output pipe 3.1, and the other end communicates with the inner chamber of the pulverized coal grinder 2 grinding assembly 2.1.

[0015] A temperature sensor 5 is provided in the chain boiler 3. In the present embodiment, the temperature sensor 5 is a remote sensing temperature control head; an elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com