Oil-layer setting packing method and special self-pressurization controller

A controller and self-pressurization technology, which is applied in the field of setting and sealing oil layer and special self-pressurizing controller, which can solve the problems of high cost, difficulty in running, and high risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

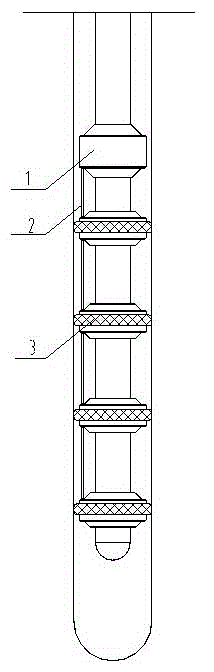

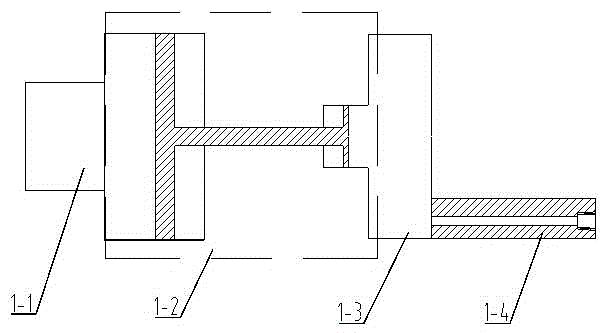

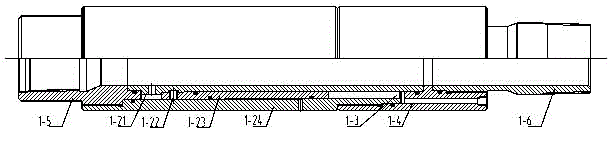

[0021] according to Figure 1-3 , a method for setting and sealing an oil layer. Firstly, the setting pipe string is lowered to a predetermined position in the downhole, and then the self-pressurization controller is activated to complete the setting of the packer; The method of setting the packer to isolate the oil layer is to install the self-pressurization control packer setting string in the downhole according to the design position requirements. The string is controlled by the self-pressurization controller 1, the hydraulic control pipeline 2. It is composed of packer 3. In this pipe string, anchors, safety joints and other tools can be connected to the upper part of the booster controller 1. At least one set of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com