Small peptide chelated zinc as well as preparation method and application thereof

A technology of small peptide chelation and inorganic zinc, which is applied in the field of feed additives, can solve problems such as few reports, achieve the effects of reducing environmental hazards, prolonging shelf life, and realizing high-value processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

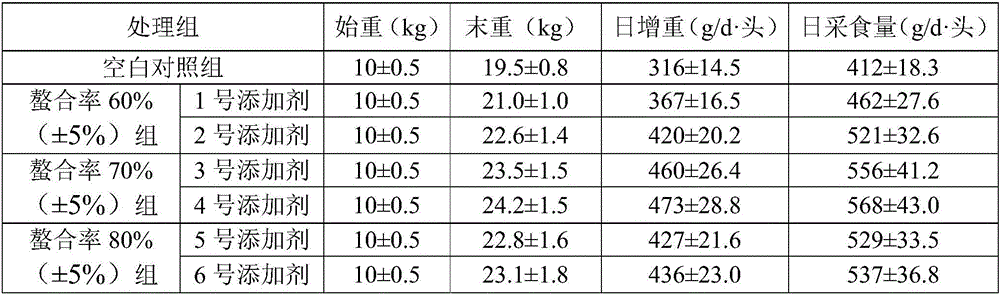

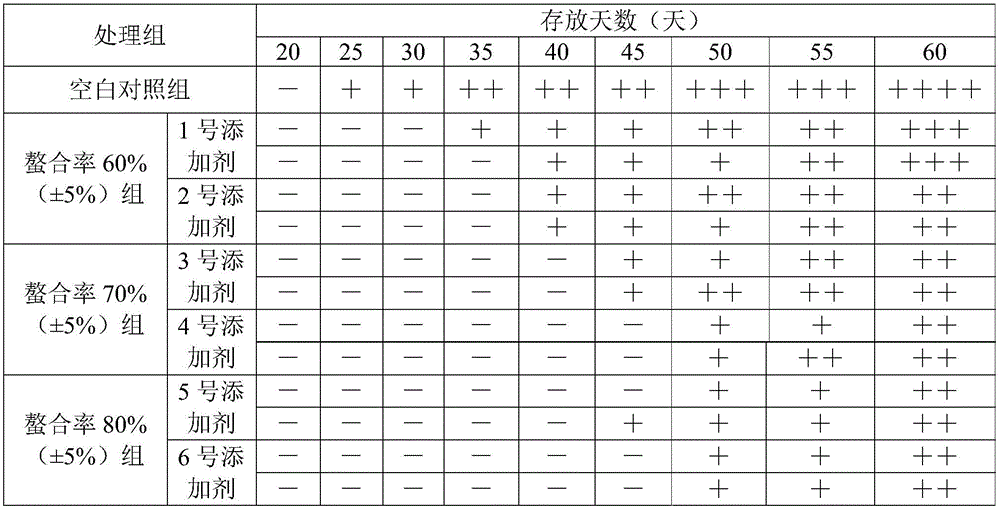

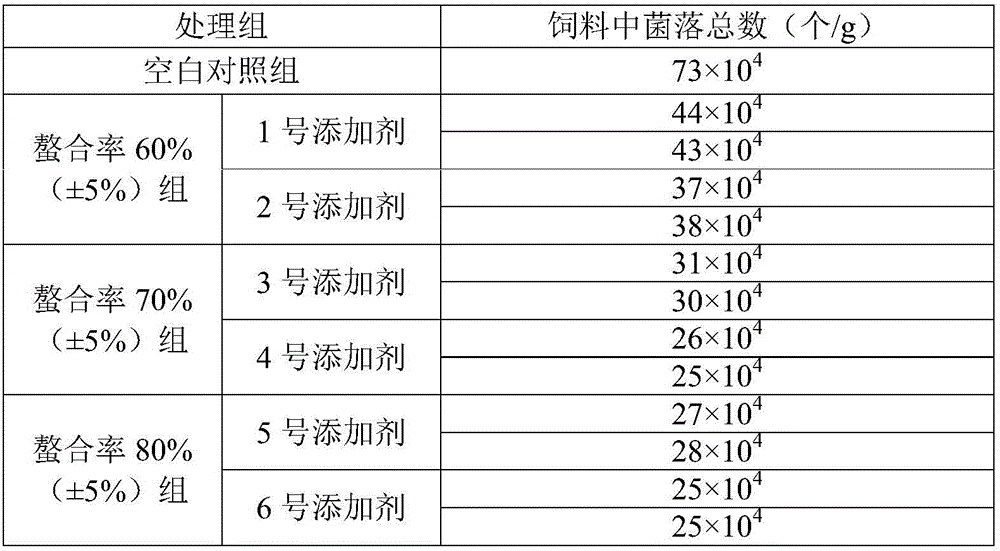

Examples

Embodiment 1

[0035] (1) Take 2000g of miscellaneous fish as the protein raw material, crush the miscellaneous fish with a meat grinder, add deionized water according to the ratio of material to liquid (mass) 1:3, adjust the pH value to 5, heat up to 50°C, and add papain , Flavor protease (papain 100,000 U / g, flavor protease 15,000 U / g, compound ratio 1:1, enzyme amount equivalent to 0.5% of trash fish mass, Nanning Pangbo Bioengineering Co., Ltd.) enzymolysis to the degree of hydrolysis 30% (Tan Zhifen et al., the assay method of the degree of protein hydrolysis. Analysis and detection, 2005), inactivate the enzyme at 100°C for 20min, centrifuge at 6000rpm for 15min, first ultrafilter with 10kDa ultrafiltration membrane, and then obtain the permeate Use 1kDa ultrafiltration, the non-permeable liquid is the trash fish protein hydrolyzate with a molecular weight between 1 and 10kDa (named A ultrafiltration protein hydrolyzate), and the permeated liquid is the trash fish protein hydrolyzate wi...

Embodiment 2

[0038] (1) Take 2000g of miscellaneous fish as the protein raw material, crush the miscellaneous fish with a meat grinder, add deionized water according to the ratio of material to liquid (mass) 1:4, adjust the pH value to 6, heat up to 60°C, add neutral Protease, flavor protease (neutral protease 300,000 U / g, flavor protease 15,000 U / g, compound ratio 1:1, the amount of enzyme added is equivalent to 0.3% of the mass of trash fish, Nanning Pangbo Bioengineering Co., Ltd.) enzymolysis to The degree of hydrolysis is 30% (Tan Zhifen et al., 2005), inactivate the enzyme at 100°C for 20 minutes, centrifuge at 6000rpm for 15 minutes, first use 10kDa ultrafiltration membrane ultrafiltration, then 1kDa ultrafiltration, and then use 1kDa ultrafiltration to obtain the permeate Ultrafiltration, non-permeable liquid is trash fish protein hydrolyzate with molecular weight between 1 and 10kDa (named A ultrafiltration protein hydrolyzate), and permeated liquid is trash fish protein hydrolyzat...

Embodiment 3

[0041](1) Take 2000g of miscellaneous fish as the protein raw material, crush the miscellaneous fish with a meat grinder, add deionized water according to the ratio of material to liquid (mass) 1:5, adjust the pH value to 7, heat up to 70°C, add neutral Protease, papain (neutral protease 300,000 U / g, papain 100,000 U / g, compound ratio 1:1, the amount of enzyme added is equivalent to 0.1% of the mass of miscellaneous fish, Nanning Pangbo Bioengineering Co., Ltd.) enzymolysis to The degree of hydrolysis is 30% (Tan Zhifen et al., 2005), inactivate the enzyme at 100°C for 20 minutes, centrifuge at 6000rpm for 15 minutes, first use 10kDa ultrafiltration membrane for ultrafiltration, and then use 1kDa to obtain the permeate. Then use 1kDa ultrafiltration, the non-permeable liquid is the trash fish protein hydrolyzate with a molecular weight between 1 and 10kDa (named A ultrafiltration protein hydrolyzate), and the permeated liquid is the trash fish protein hydrolyzate with a molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| Chelation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com