Chemical enhancement method of high-alkalinity aluminum silicate glass with controllable surface stress

A silicate glass, surface stress technology, applied in the field of glass deep processing, can solve the problems of reducing the internal tensile stress of the glass, making the glass not easy to self-explosion, etc., achieving the effects of no environmental pollution, not easy to self-explosion, scratch resistance and increased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

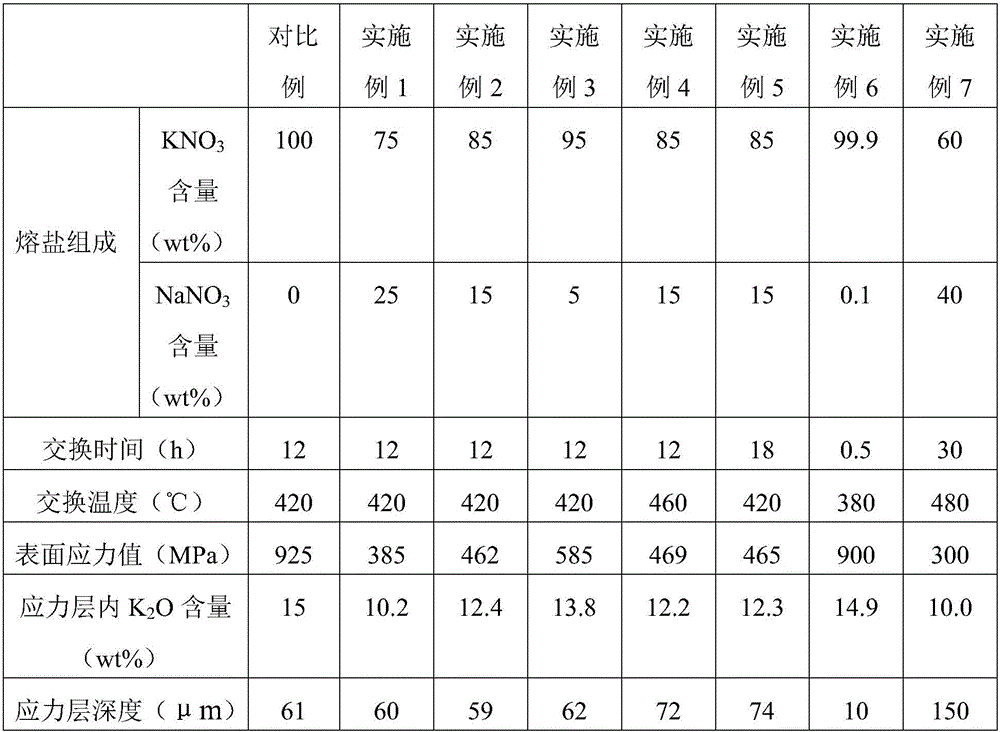

Embodiment 1

[0032] According to 75wt% KNO 3 and 25wt% NaNO 3 Proportional configuration of molten salt 10kg, put into the salt tank, melt and clarify in the muffle furnace for 24 hours. Clamp the processed glass sample with a clamp, preheat it in a high-temperature furnace for 15 minutes, and then immerse it in a molten salt bath for ion exchange. The exchange time is set to 12h, and the exchange temperature is 420°C. After the exchange, the fixture was taken out from the molten salt, and after cooling down to room temperature, the glass sample was cleaned with deionized water and wiped clean for testing.

[0033] Test the chemically strengthened glass sample: the surface and edge of the glass are of good quality without deformation; the FSM-6000LE automatic surface stress meter of Suzhou Jingchuang Optical Instrument Co., Ltd. is used to test the chemically strengthened glass sample, and the surface stress The size is 385MPa, and the stress layer depth is 60μm.

Embodiment 2

[0038] According to 85wt% KNO 3 and 15wt% NaNO 3 Proportional configuration of molten salt 10kg, put into the salt tank, melt and clarify in the muffle furnace for 24 hours. Clamp the processed glass sample with a clamp, preheat it in a high-temperature furnace for 15 minutes, and then immerse it in a molten salt bath for ion exchange. The exchange time is set to 12h, and the exchange temperature is 420°C. After the exchange, the fixture was taken out from the molten salt, and after cooling down to room temperature, the glass sample was cleaned with deionized water and wiped clean for testing.

[0039] Test the chemically strengthened glass sample: the surface and edge of the glass are of good quality without deformation; the FSM-6000LE automatic surface stress meter of Suzhou Jingchuang Optical Instrument Co., Ltd. is used to test the chemically strengthened glass sample, and the surface stress The size is 462MPa, and the stress layer depth is 59μm.

Embodiment 3

[0041] According to 95wt% KNO 3 and 5wt% NaNO 3 Proportional configuration of molten salt 10kg, put into the salt tank, melt and clarify in the muffle furnace for 24 hours. Clamp the processed glass sample with a clamp, preheat it in a high-temperature furnace for 15 minutes, and then immerse it in a molten salt bath for ion exchange. The exchange time is set to 12h, and the exchange temperature is 420°C. After the exchange, the fixture was taken out from the molten salt, and after cooling down to room temperature, the glass sample was cleaned with deionized water and wiped clean for testing.

[0042] Test the chemically strengthened glass sample: the surface and edge of the glass are of good quality without deformation; the FSM-6000LE automatic surface stress meter of Suzhou Jingchuang Optical Instrument Co., Ltd. is used to test the chemically strengthened glass sample, and the surface stress The size is 585MPa, and the stress layer depth is 62μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com