Preparation method of nano zinc oxide transparent ethanol solution

A technology of nano-zinc oxide and transparent alcohol, which is applied in the field of preparation of nano-zinc oxide transparent alcohol solution, and can solve the problems of complex preparation route, high synthesis cost, and poor stability of ultra-fine nano-zinc oxide particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

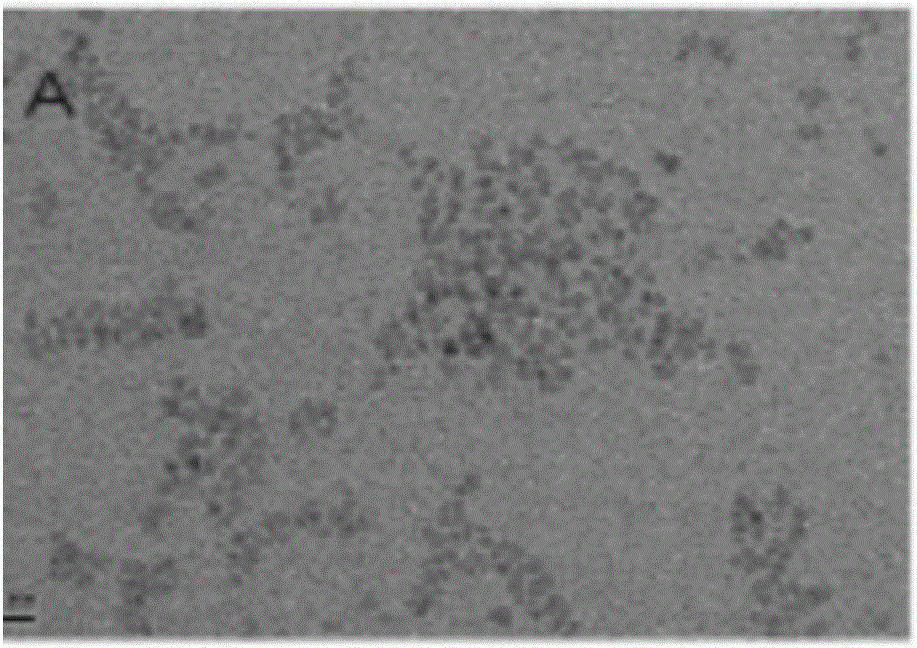

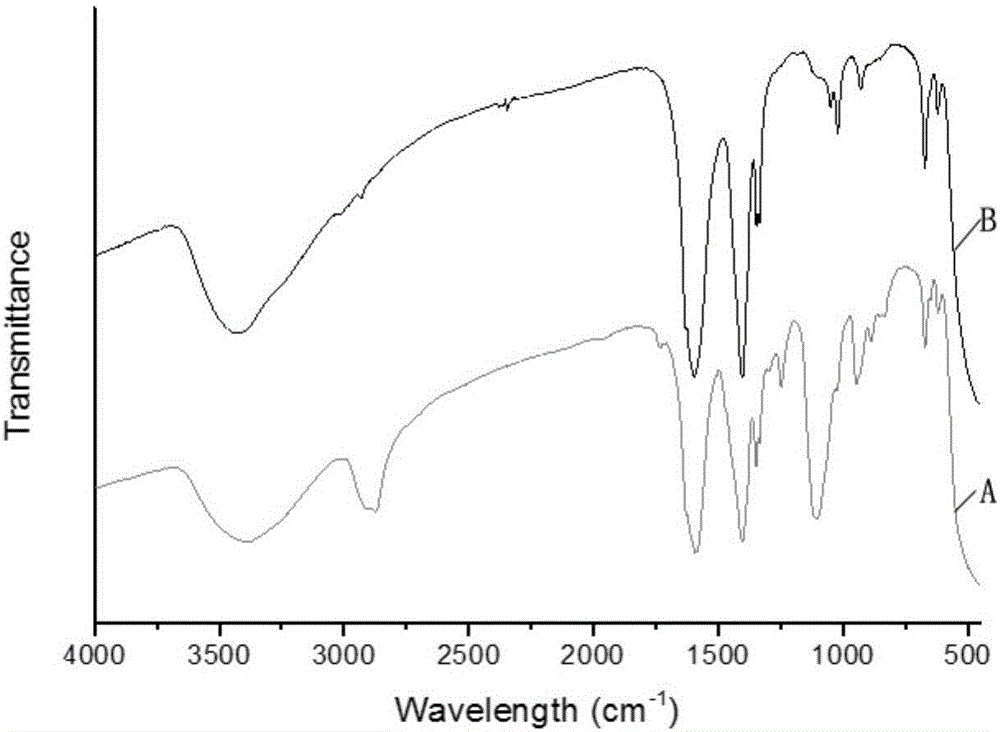

[0023] Dissolve 10.0 mmol of sodium hydroxide in 100.0 mL of ethanol (equivalent to 1.7 mol of ethanol), and stir at 50°C for 20 minutes to prepare a sodium hydroxide solution. At the same time, 10.0 mmol Zn(AC) 2 2H 2 O was dissolved in 100.0 mL of ethanol, stirred at 65°C for 20 minutes, then cooled to 50°C, added 5.0 mL of PEG-200, stirred at 50°C for 10 minutes to prepare a zinc acetate solution. Finally, 100.0 mL of sodium hydroxide solution was quickly added to 101.0 mL of zinc acetate solution, and the stirring reaction was continued at 50° C. for 20 to 800 minutes to obtain a transparent nanometer zinc oxide ethanol solution.

[0024] The nano-zinc oxide ethanol solutions obtained at different reaction times were stored at 4°C. In order to obtain PEG-modified zinc oxide nanoparticles, 200 mL of distilled water was added to the nano-zinc oxide ethanol solution prepared by the reaction, and then centrifuged at 4000 rpm for 5 minutes, the supernatant was poured out, and...

Embodiment 2

[0026]Dissolve 10.0 mmol of sodium hydroxide in 100.0 mL of ethanol and stir at 50°C for 20 minutes to prepare a sodium hydroxide solution. At the same time, dissolve 10.0 mmol zinc acetate in 100.0 mL ethanol, stir at 65°C for 20 minutes, then cool to 50°C, add 1.0mL PEG-200, stir at 50°C for 10 minutes to make a zinc acetate solution. Finally, 100.0 mL of sodium hydroxide solution was quickly added to 101.0 mL of zinc acetate solution, and the stirring reaction was continued at 50°C for 20 minutes to obtain a transparent nano-zinc oxide ethanol solution, which could remain clear and transparent for more than 6 months.

Embodiment 3

[0028] Dissolve 10.0 mmol of sodium hydroxide in 100.0 mL of ethanol and stir at 50°C for 20 minutes to prepare a sodium hydroxide solution. At the same time, dissolve 10.0 mmol zinc acetate in 100.0 mL ethanol, stir at 65°C for 20 minutes, then cool to 50°C, add 3.0mL PEG-200, stir at 50°C for 10 minutes to make a zinc acetate solution. Finally, 100.0 mL of sodium hydroxide solution was quickly added to 101.0 mL of zinc acetate solution, and the stirring reaction was continued at 50°C for 40 minutes to obtain a transparent nano-zinc oxide ethanol solution, which could remain clear and transparent for more than 6 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com