A kind of automatic shaping tooling and shaping method of lithium-ion battery module

A lithium-ion battery, automatic technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of tightening tooling of damaged modules, inconvenient operation, and affecting production efficiency, so as to optimize the process flow, improve product quality, and improve The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

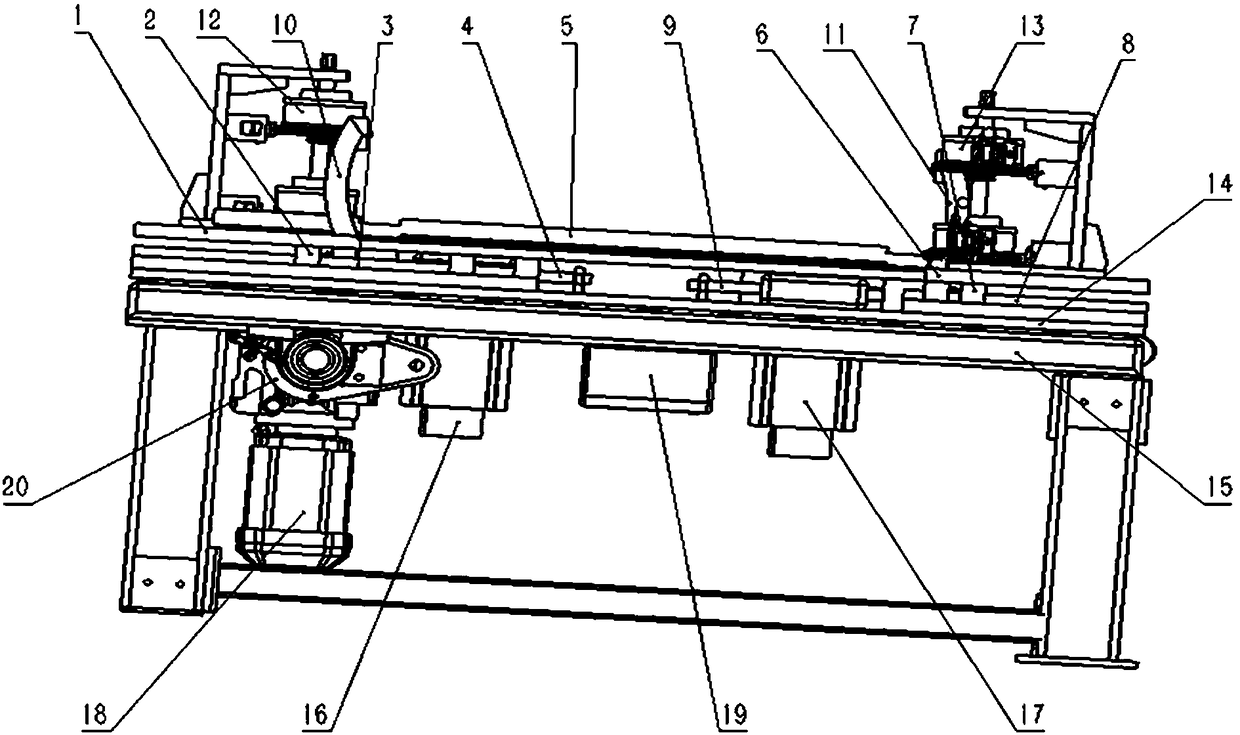

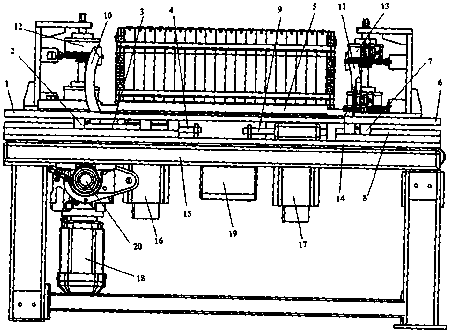

[0025] The following combination Figure 1 ~ Figure 2 , a preferred embodiment of the present invention is described in detail.

[0026] Such as figure 1 and figure 2 As shown, the automatic shaping tooling of the lithium ion battery module provided by the present invention includes: a base 15; a base plate 14, which is arranged on the base 15, and can move left and right along the base 15; a support plate 5, which is fixedly arranged on the base plate 14, and For placing the lithium-ion battery module; PLC 19 is arranged under the base 15; two shaping and tightening components are respectively arranged at the left and right ends of the bottom plate 14, and are not connected with the support plate 5, and are respectively moved along the bottom plate under the control of the PLC 19. 14 moves left and right to clamp or loosen the lithium-ion battery module placed on the support plate 5 to realize the shaping and tightening of the lithium-ion battery module; the transmission a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com