Packaging and shaping device for bagged FOSBs sealed by ultrasonic waves

A shaping device, ultrasonic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low efficiency and low degree of automation, achieve high efficiency, reduce labor costs, and cooperate closely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

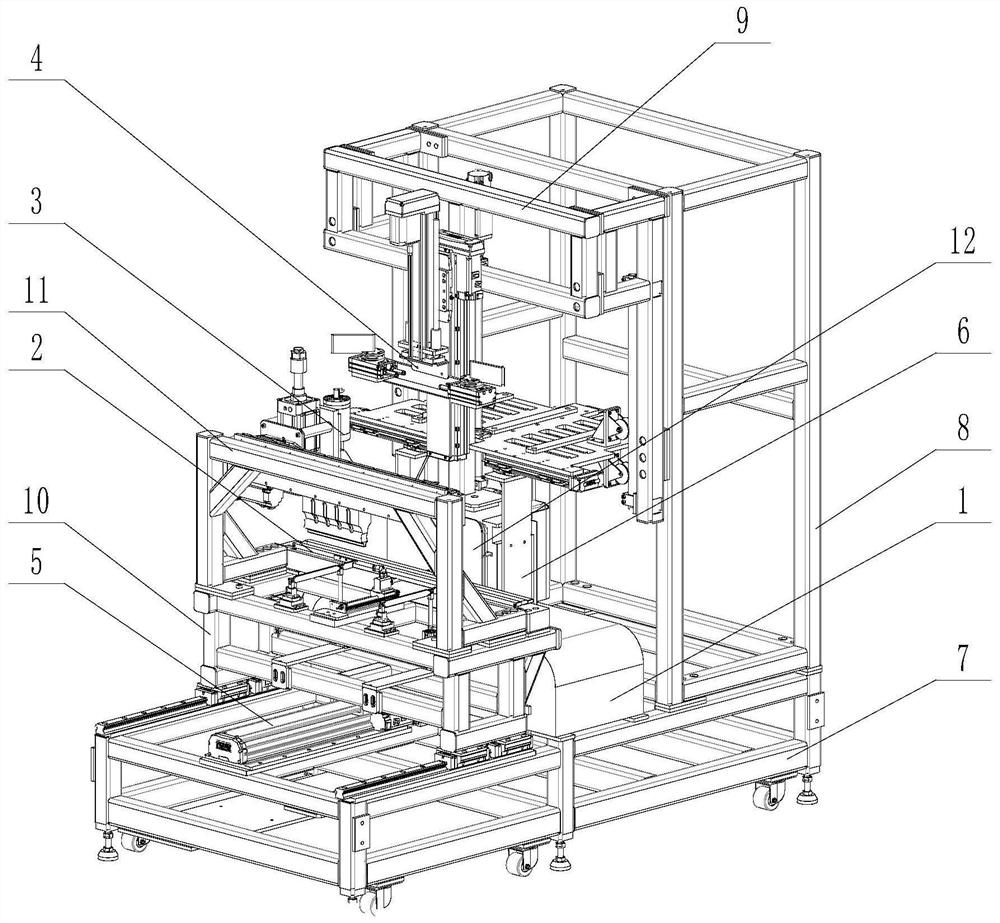

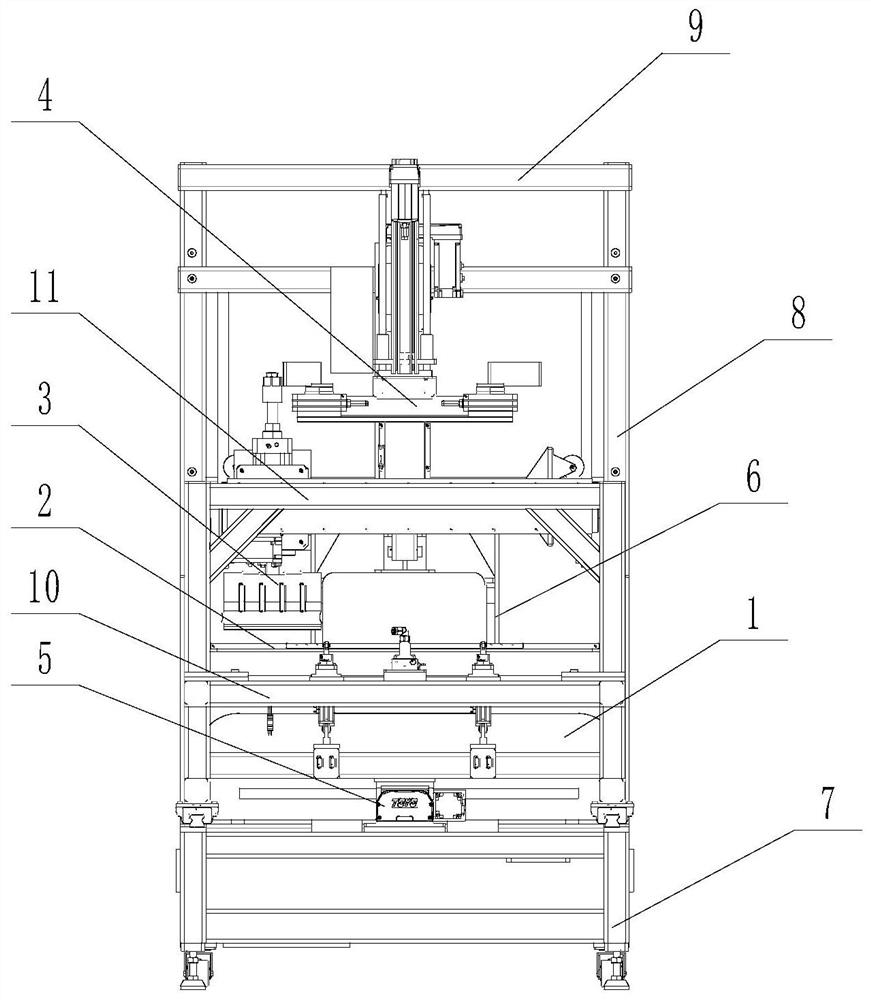

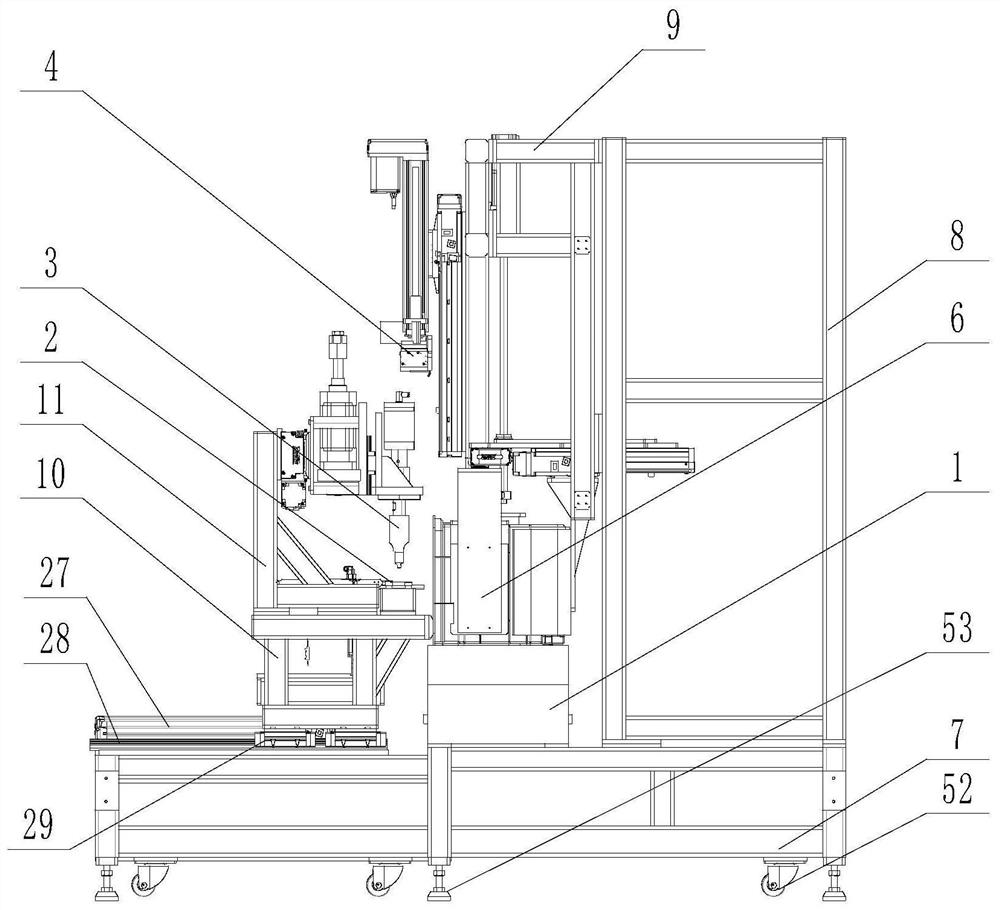

[0041] The present invention will be further described below in conjunction with accompanying drawing:

[0042] Such as Figure 1-10 As shown, a bagging FOSB packaging shaping device utilizing ultrasonic sealing includes an overall frame, a FOSB conveyor belt 1, a clamping device 2, an ultrasonic sealing device 3, a FOSB front-end shaping device 4, a sealing station horizontal driving device 5 and FOSB dorsal side shaping device6. The present invention has two stations, a sealing station and a shaping station, wherein the horizontal driving device 5 of the sealing station, the clamping device 2 and the ultrasonic sealing device 3 all belong to the sealing station, and the FOSB conveyor belt 1, the FOSB front-end shaping device 4 and The FOSB back and side shaping device 6 belongs to the shaping station.

[0043] Described overall frame comprises shaping station bottom frame 7, shaping station rear side frame 8, shaping station front side frame 9, sealing station lower frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com