Screening machine for feed granulation

A feed granulation and granulation technology, applied in feed, application, food science and other directions, can solve problems such as low efficiency and difficulty in forming feed, and achieve the effect of improving work efficiency and uniform granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

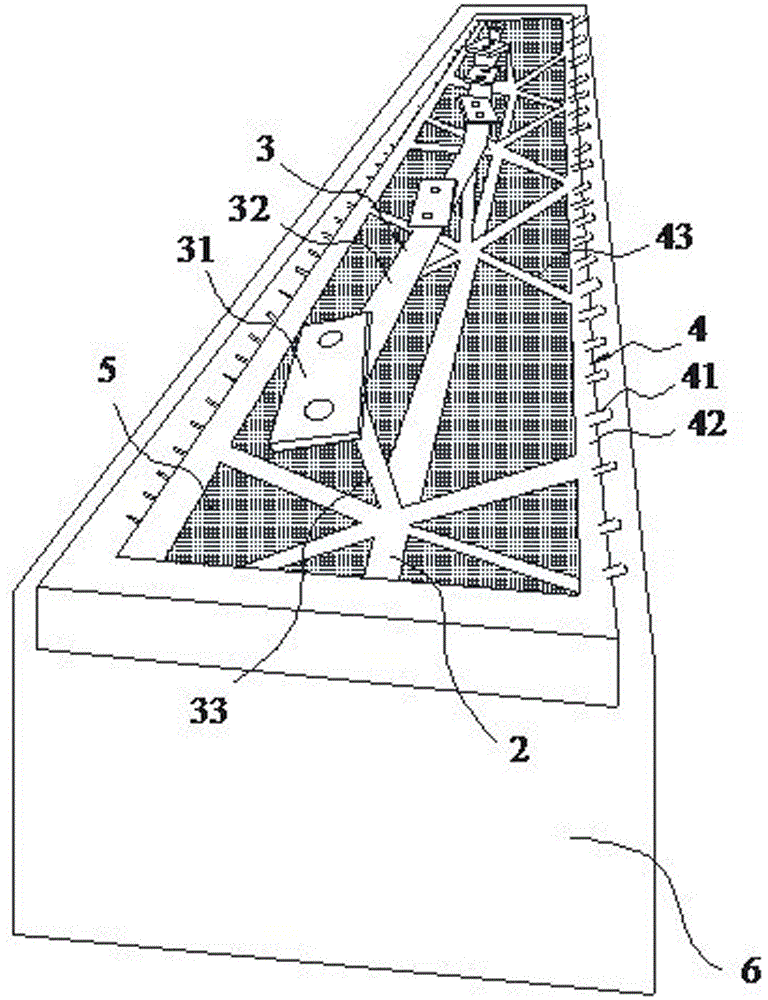

[0017] Such as Figure 1-2 A sieve machine for feed granulation is shown, including a rotary drive mechanism 1, a rotary mandrel 2, an extrusion plate 3, a nail rake 4, a screen 5 and a collection tank 6, and the screen 5 is sealed on the aggregate The notch of the slot 6, the rotating mandrel 2 is pivotally mounted on the collecting tank 6 and is located above the screen 5; the nail rake 4 and the extruding plate 3 are multiple, centered on the rotating mandrel 2 and fixed in a radial distribution on the The outer periphery of the rotating mandrel 2, the extrusion plate 3 and the screen 5 are in clearance fit, the nail rake 4 is slidingly matched with the screen 5, and the rotating drive mechanism 1 is synchronously linked with the rotating mandrel 2 and is used to drive the rotating mandrel 2 to rotate.

[0018] When the feed falls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com