Automatic pelletizing and molding device

A molding device and automatic technology, applied in the direction of raw material extrusion granulation, etc., can solve the problems of uneven hollow inner diameter of granules, easy breakage of hollow strip materials, uneven granules, etc., to achieve easy drying, stable falling speed, and granulation uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

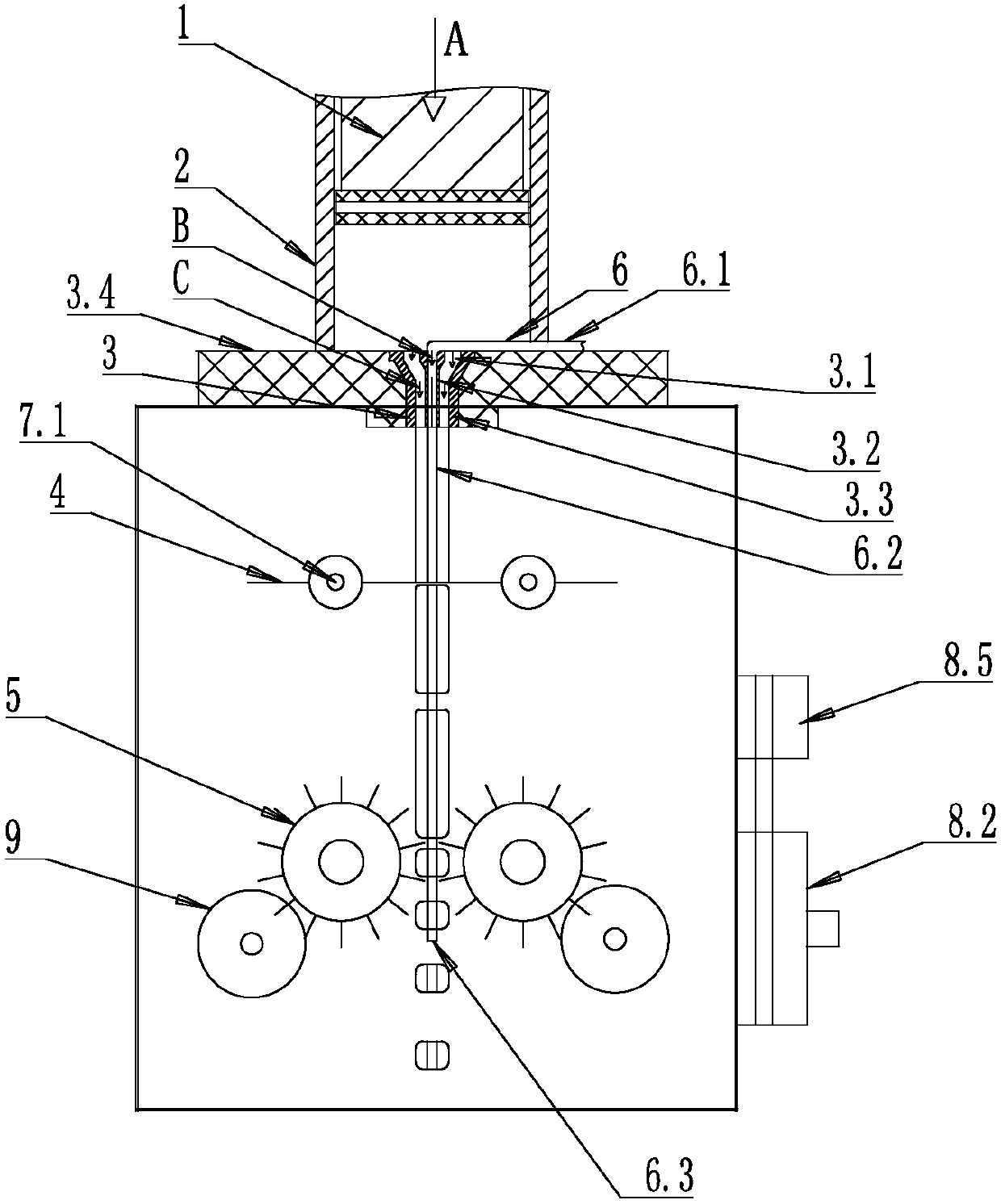

[0038] like Figure 1 ~ Figure 3 As shown, the automatic granulation molding device of the present invention includes a material extrusion part 2, a mold 3 is provided at the discharge end of the material extrusion part 2, and the mold 3 includes a mold body 3.3, and an inner core 3.2 is arranged in the middle of the mold body 3.3. , a discharge channel 3.1 is provided between the mold body 3.3 and the inner core 3.2, and a conduit 6 is provided through the inner core 3.2; the conduit 6 includes a connected fixed section 6.1 and a guide section 6.2, and the fixed section 6.1 and the guide section 6.2 are bent and fixed. Section 6.1 is arranged on the upper part of mold 3, and guide section 6.2 is worn in inner core 3.2.

[0039] The conduit 6 is a hollow conduit, the guide section 6.2 of the hollow conduit is provided with a lubricating hole, and the fixed section 6.1 communicates with the hydraulic pump. The end of the guide section 6.2 is designated as a closed end 6.3. Th...

Embodiment 2

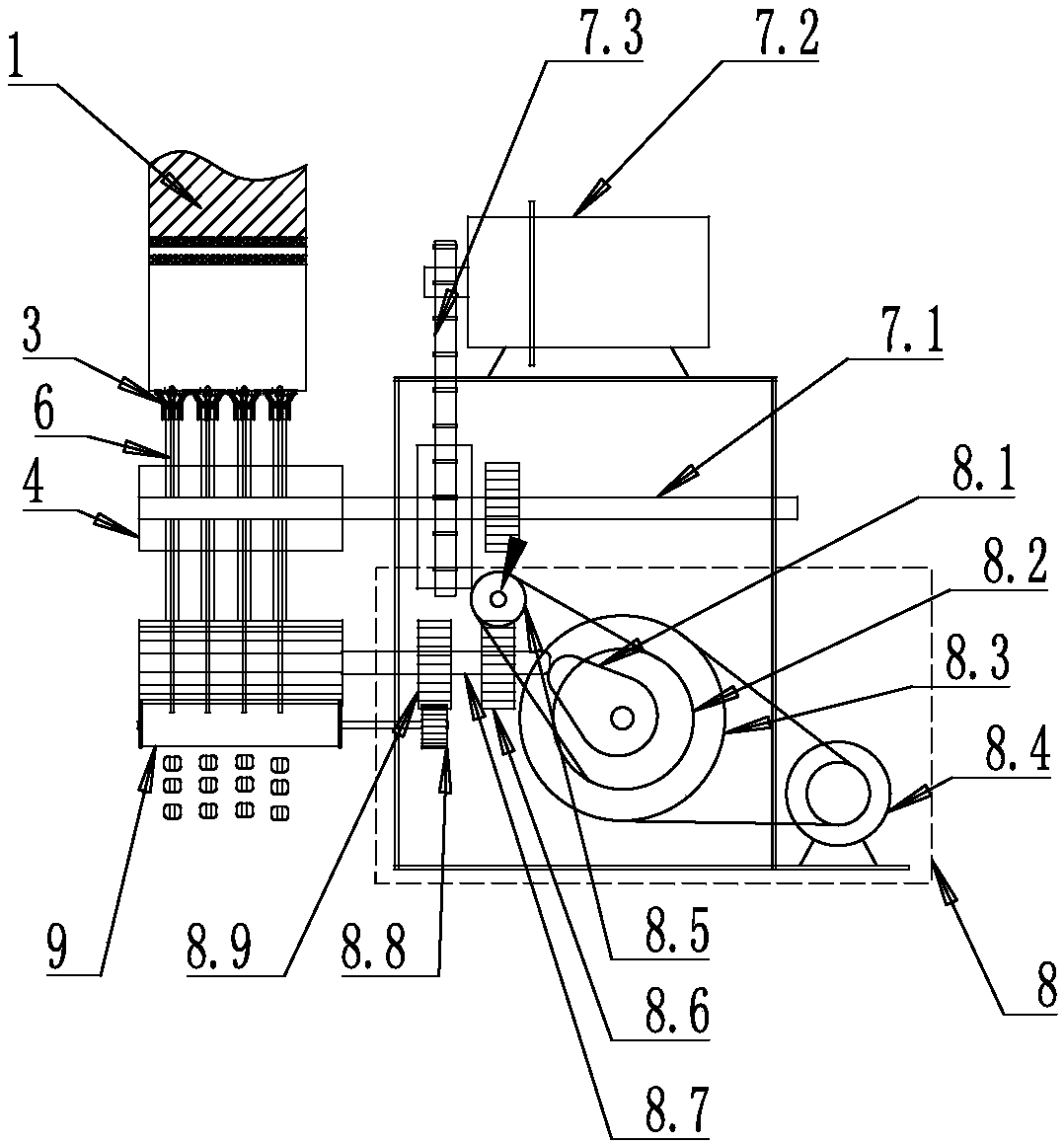

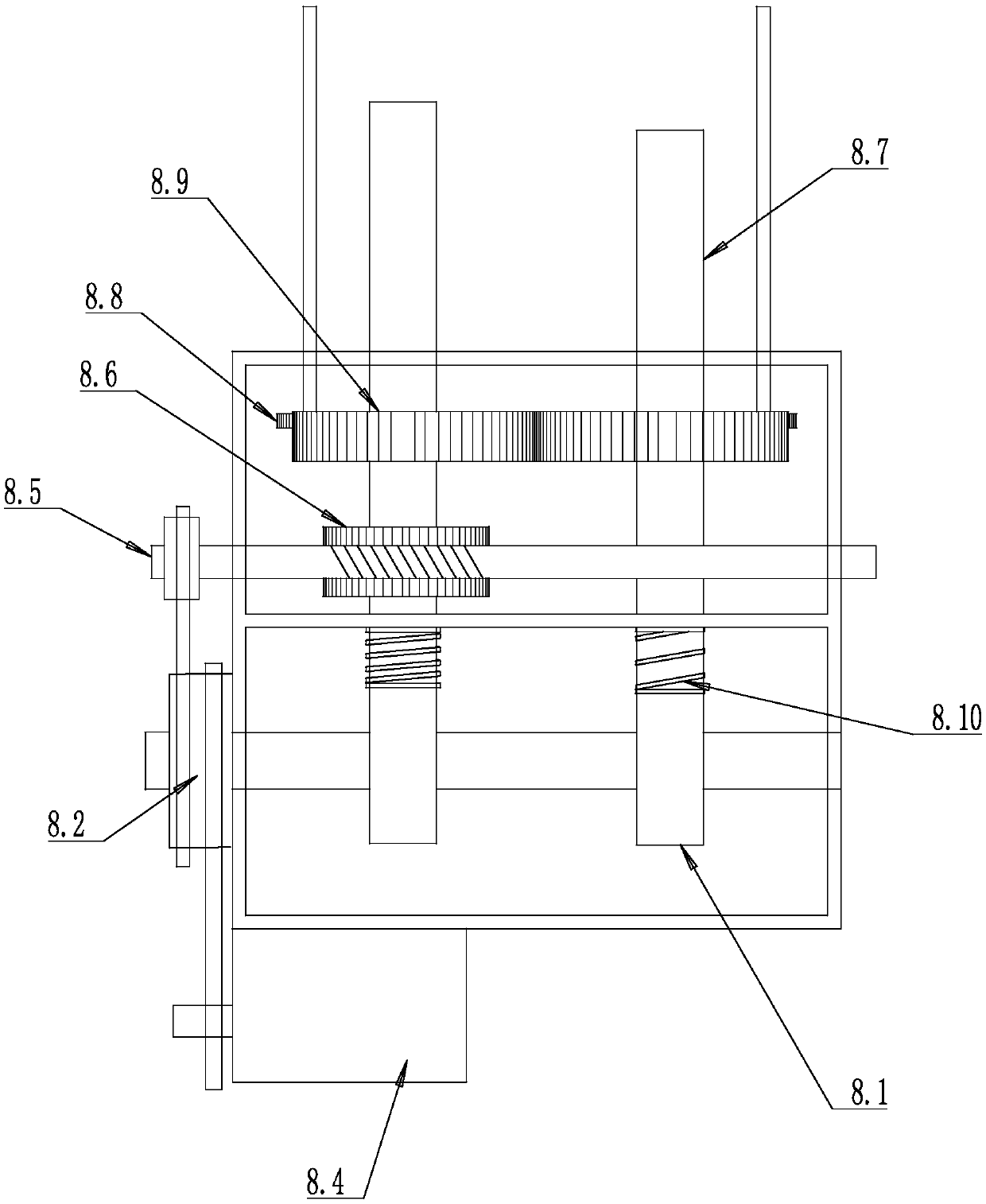

[0046] like Figure 1 ~ Figure 3 As shown, a cutter 4 is provided between the mold 3 and the rubbing roller 5 . Two cutters 4 are correspondingly arranged along both sides of the conduit 6 , the cutters 4 are arranged on the cutter shaft 7.1 , and the cutter shaft 7.1 is vertically arranged with the conduit 6 . The cutter shaft 7.1 is connected to the cutter driving device through the transmission chain 7.3, and the cutter driving device can be the cutter motor 7.2. At least two sets of cutters 4 are correspondingly arranged on the two corresponding cutter shafts 7.1. All the other are with embodiment 1.

[0047] In the prior art, the inner core 3.2 provided in the middle of the mold 3 is solid. After the material 1 is extruded into a strip shape, the middle becomes a hollow strip shape because of the inner core 3.2. However, the strip material often breaks during the falling process Moreover, the fractures and cracks are not uniform, resulting in uneven size of the granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com