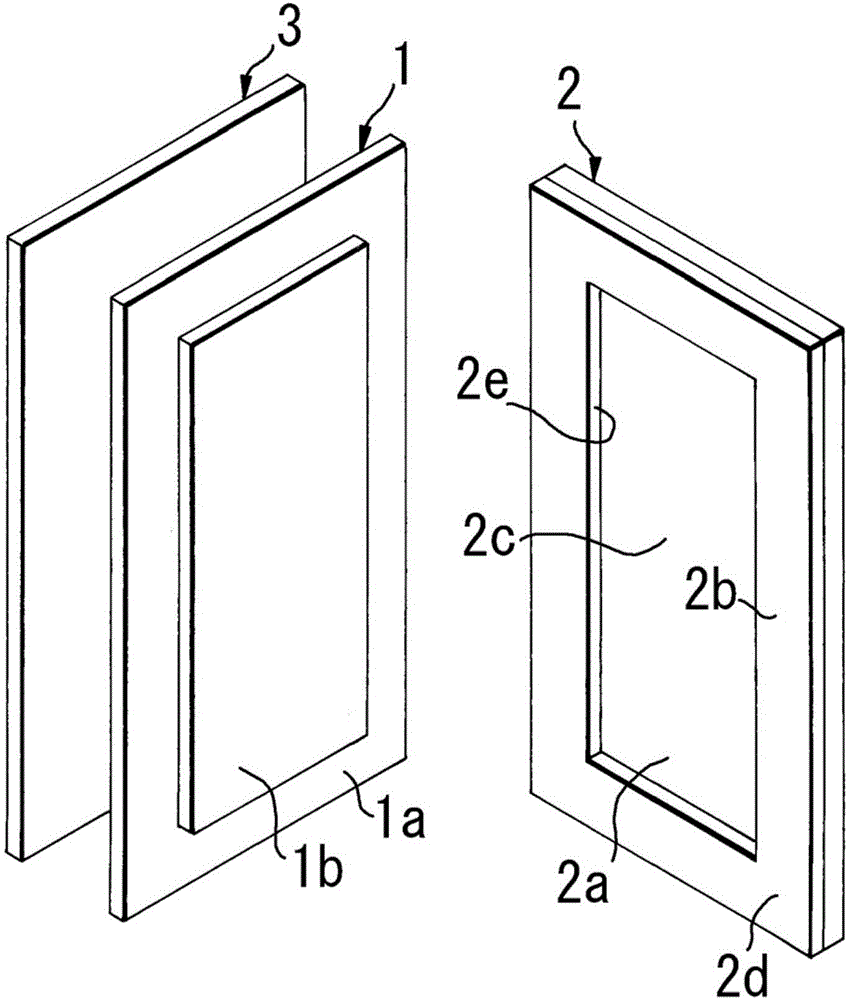

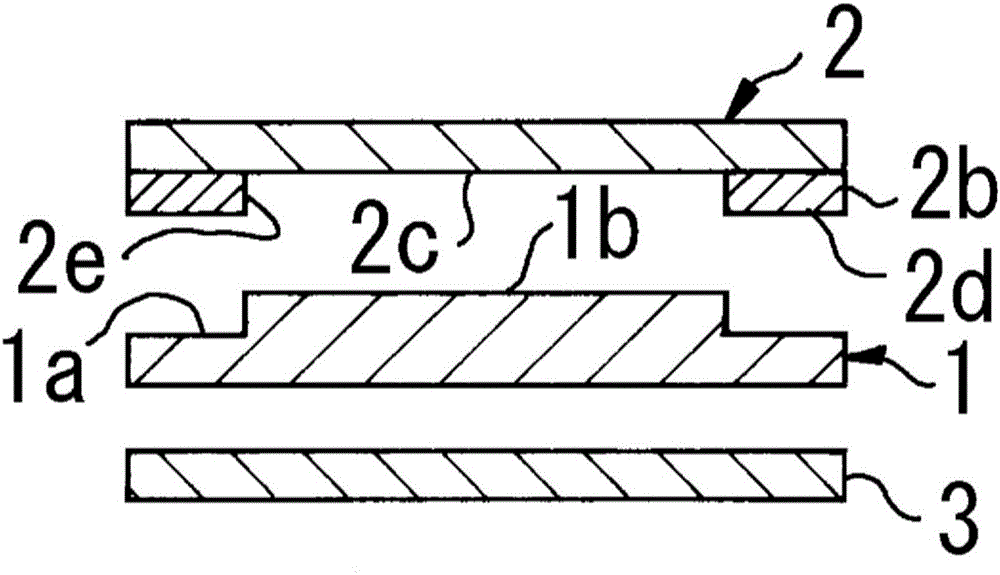

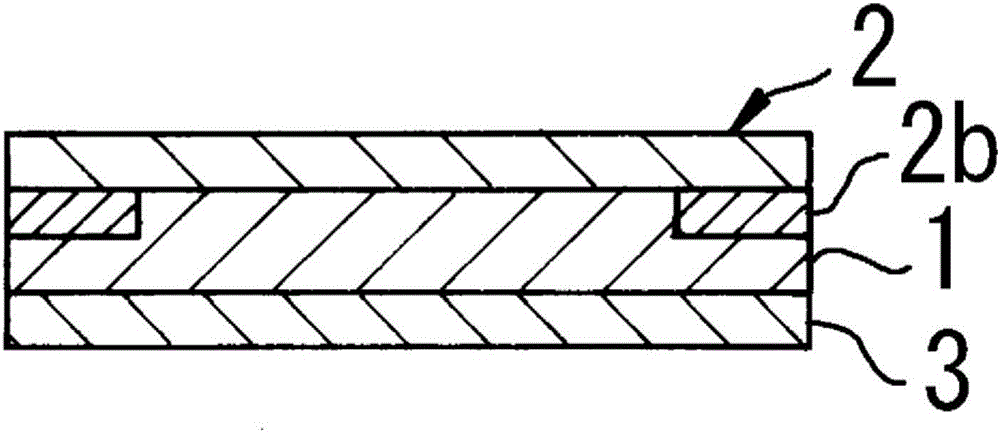

Method for manufacturing double-sided adhesive sheet for image display device

A technology of image display device and manufacturing method, applied in the direction of identification device, film/sheet adhesive, adhesive, etc., capable of solving problems such as resin overflow, polluted electrodes, wiring, solvent cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0181] Hereinafter, it demonstrates in more detail using an Example and a comparative example. However, the present invention is not limited thereto.

[0182] First, in order to produce the double-sided pressure-sensitive adhesive sheet of the present invention, a pressure-sensitive adhesive sheet (S-0) was produced by the following production examples.

manufacture example

[0184] Prepare 50 parts by weight of 2-ethylhexyl acrylate (homopolymer Tg (glass transition point of a polymer obtained by polymerizing only 2-ethylhexyl acrylate): -70°C), vinyl acetate (homopolymer Acrylate copolymer A (Mn=65400, Mw=167000, Mw / Mn=2.56) obtained by random copolymerization of 45 parts by weight of Tg+32°C) and 5 parts by weight of acrylic acid (homopolymer Tg+106°C). In 1 kg of this acrylate copolymer A, 70 g of ultraviolet curable resin propoxylated pentaerythritol triacrylate (Shin-Nakamura Industry Co., Ltd. "ATM-4PL") as a crosslinking agent and 4-methyl 15 g of benzophenone was used to prepare a binder resin composition (A-1).

[0185] On the one side of a stretched polyethylene terephthalate film (manufactured by PANAC Co., Ltd., stretched PET film "NP75Z01", thickness 75 μm) that has been treated on one side in a peelable manner, the above-mentioned The adhesive resin composition (A-1) was heat-melted and applied with an applicator to a thickness of 1...

Embodiment 1

[0187] (Preparation of Adhesive Sheet 1)

[0188] The stretched PET film "E7006" was peeled off from the pressure-sensitive adhesive sheet (S-0) produced above, and it became the pressure-sensitive adhesive sheet 1. Table 1 shows the evaluation results of the physical properties of PSA Sheet 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com