Power source of elevator contracting brake

A technology for elevators and power supplies, applied to electrical components, adjusting electrical variables, instruments, etc., can solve problems such as increased fault points and later maintenance costs, large DC voltage pulsation components, insufficient opening of brakes, etc., to achieve later maintenance Low cost, less power supply, and fewer circuit failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

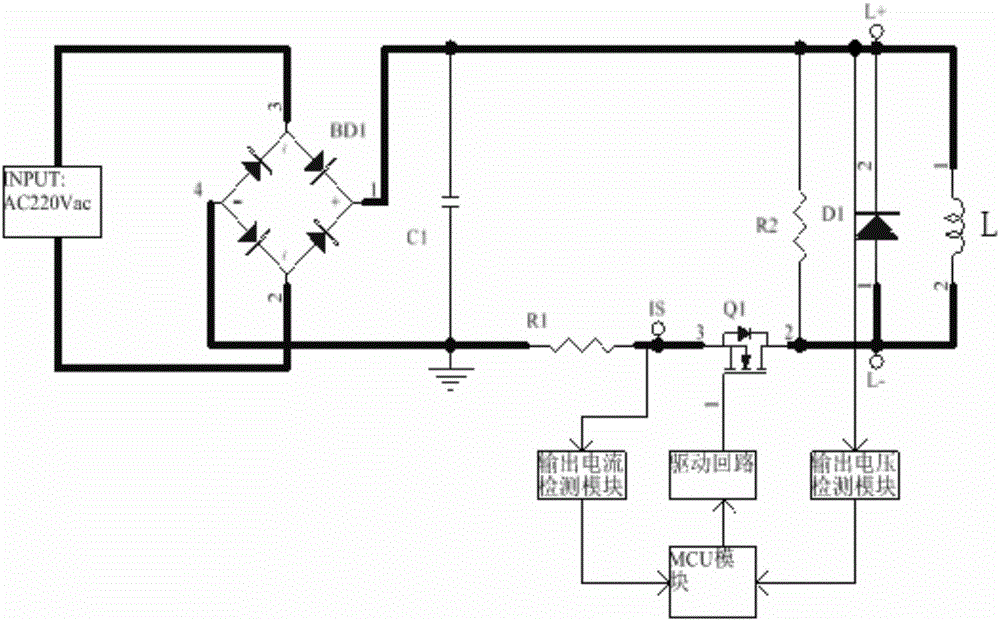

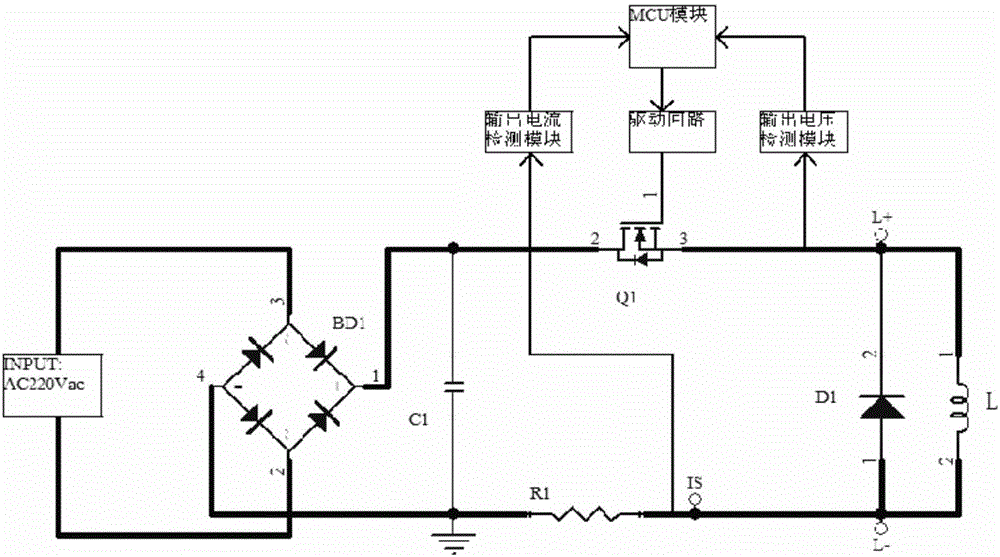

[0021] The principle of the elevator brake power supply in Embodiment 1 of the present invention is as follows: figure 1 As shown, it includes a DC power supply and a chopper circuit (DC / DC conversion circuit), and the elevator brake includes a brake coil L. The input terminal of the chopper circuit is connected with a DC power supply, and the output terminal of the chopper circuit is connected with the brake coil L.

[0022] The chopper circuit includes a microcontroller (MCU), a MOS transistor Q1, a freewheeling diode D1, a voltage detection resistor R2, an output current detection circuit, an output voltage detection circuit and a drive circuit for the MOS transistor Q1.

[0023] The freewheeling diode D1 is connected in parallel with the brake coil L, the anode is connected to the negative pole of the output end of the chopper circuit, and the cathode is connected to the positive pole of the output end of the chopper circuit. The voltage detection resistor R2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com