Protective jacket for transformer respirator

A respirator, transformer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

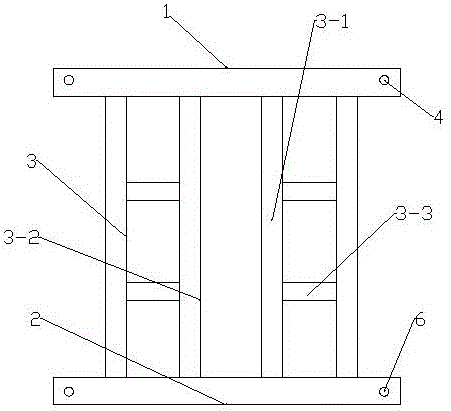

[0011] like figure 1 As shown, a protective cover for a transformer respirator includes an upper tight part 1 and a lower tight part 2, the upper tight part 1 and the lower tight part 2 are arranged in parallel, and the upper tight part 1 and the lower tight part A number of connecting element groups 3 are arranged vertically between the tightening elements 2 .

[0012] The upper tightening part 1, the lower tightening part 2 and the connector group 3 are integrally formed. The material of the upper tightening part 1, the lower tightening part 2 and the connecting part group 3 is butyl rubber or halogenated butyl rubber. This material has better high temperature resistance and oxidation resistance than natural rubber, and can ensure a longer service life outdoors.

[0013] The connector group 3 includes a first connector 3-1 and a second connector 3-2, the first connector 3-1 and the second connector 3-2 are parallel to each other and perpendicular to the upper tight member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com