Temperature control system and optical console

A technology of temperature control system and temperature controller, which is applied in the direction of temperature control using digital devices, temperature control using electric methods, refrigeration and liquefaction, etc., which can solve the problems of slow temperature change in temperature control systems, heavy testing work, and long test cycles, etc. problems, to achieve the effect of increasing the temperature change rate, saving test time, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The structure of the temperature control system of the present embodiment is as follows:

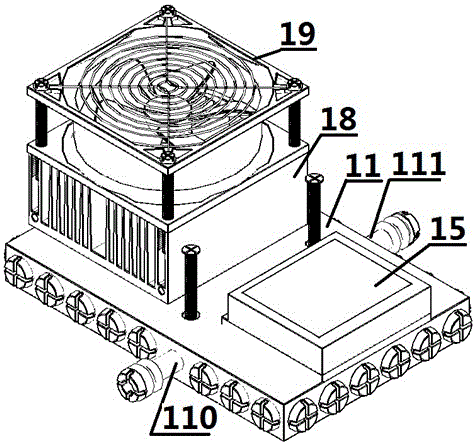

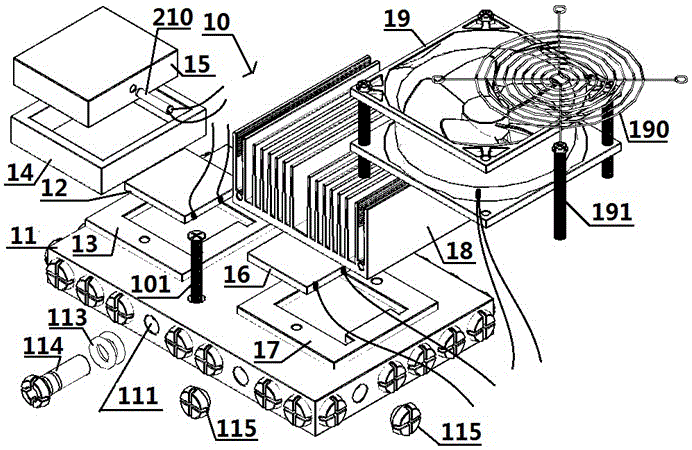

[0064] Please combine Figure 1-3 It should be understood that the temperature control system of this embodiment includes a refrigeration unit 10, a temperature controller 20 and a switching power supply 30, the temperature controller 20 can control the switching power supply 30 to drive the refrigeration unit 10 to cool or heat,

[0065] The refrigeration unit 10 includes a copper heat dissipation support plate 11, a first refrigeration sheet 12, a first heat insulation pad 13, an annular heat insulation sheet 14, a temperature control copper block 15, a second refrigeration sheet 16, and a second heat insulation pad 17. Radiating block 18,

[0066] The heating surface and the cooling surface of the first refrigerating sheet 12 are respectively in thermal contact with the copper heat dissipation support plate 11 and the temperature control copper block 15 respectively, and the f...

Embodiment 2

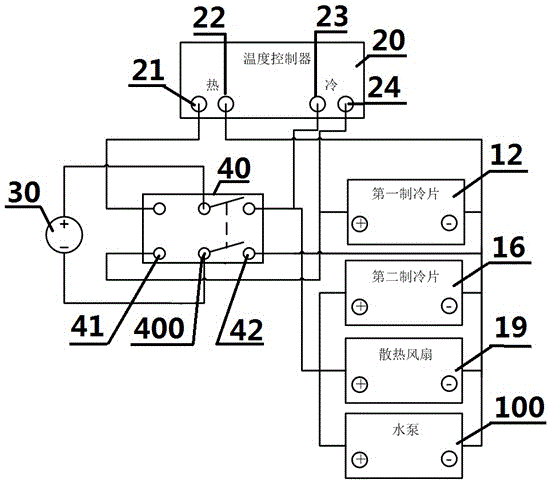

[0080] The structure of the temperature control system of the present embodiment is as follows:

[0081] The temperature control system of this embodiment has many similarities with the temperature control system of Embodiment 1, and these similarities will not be repeated. It is different from the temperature control system of Embodiment 1. Please combine Image 6 It should be understood that the circuit elements of the switching power supply 30 and the circuit elements of the temperature controller 20 are integrated on the same PCB board, and the switching power supply 30 includes a transformer unit T1, a rectifier unit D1~D4, and a filter unit electrically connected in sequence C1 and a voltage stabilizing unit IC1; the temperature controller 20 includes a wireless transceiver unit W1, a temperature acquisition unit U1, a signal processing unit IC2 and an H-bridge circuit with enabling control and direction logic, and the H-bridge circuit has An enabling terminal ENABLE, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com