Small-size rotating type diamond anvil cell press device

A diamond top-to-top and rotary technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of not being able to apply shear to the sample at the same time, and achieve the effect of in-situ measurement, small size, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 illustrates the structure of the small rotary diamond anvil press of the present invention in conjunction with the accompanying drawings

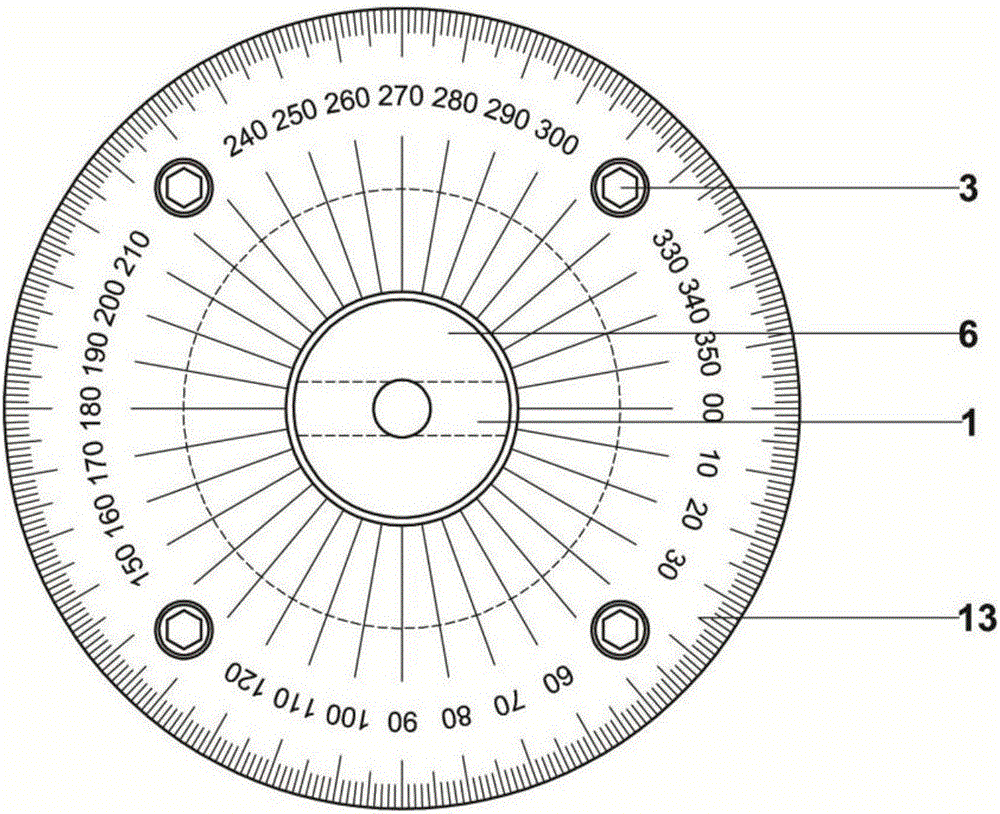

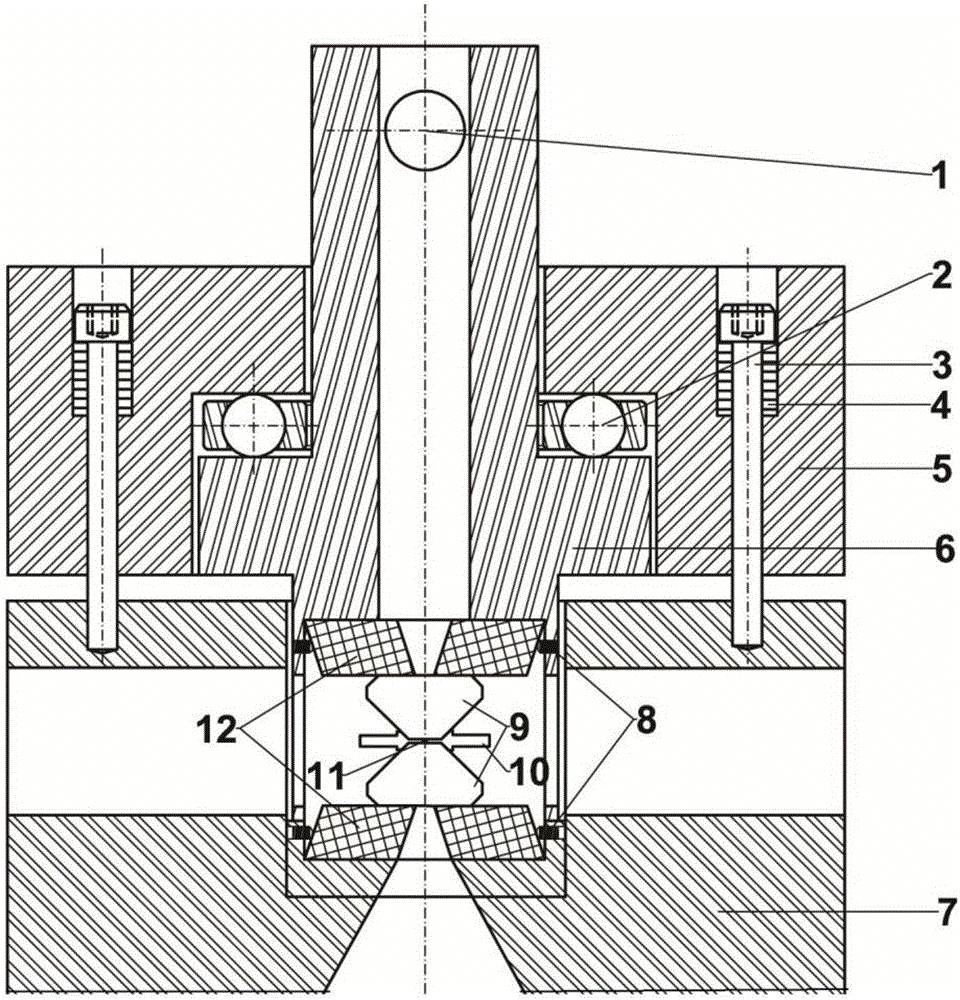

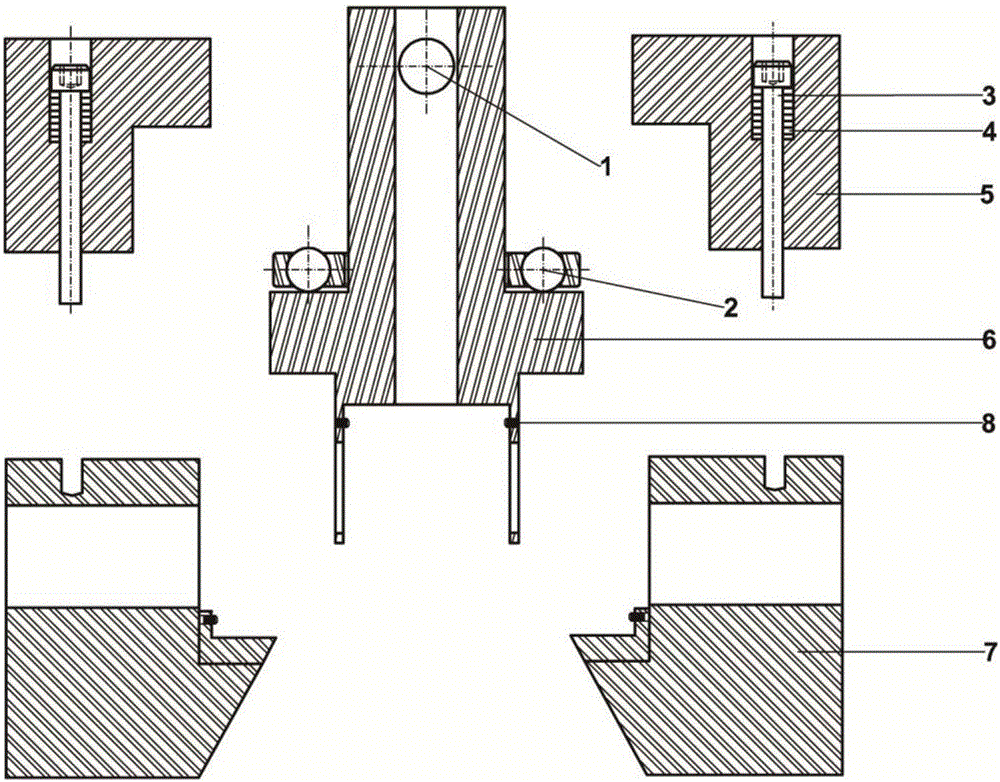

[0021] The structure of the small rotary diamond anvil press of the present invention is as attached Figure 1~6 shown. The structure includes the rotating rod socket 1, the ball bearing 2, the pressure screw 3, the disc spring sheet 4, the upper outer cylinder of the press 5, the inner piston of the press 6, the lower outer cylinder of the press 7, the fastening screw 8, Diamond anvil 9, spacer 10, sample cavity 11, support block 12, press dial 13, rotating rod 14 and scale line 15 of the dial. The outer wall of the inner piston 6 of the press can be tightly fastened with the inner wall of the upper outer cylinder 5 of the press and the inner wall of the lower outer cylinder 7 of the press, and the ball bearing 2 is placed between the upper outer cylinder 5 of the press and the inner piston 6 of the press , the diamon...

Embodiment 2

[0024] Embodiment 2 The assembly process of the small rotary diamond anvil press of the present invention

[0025] First clean the two diamond anvils 9, and then fix the diamond anvils 9 on the support block 12 with a repair agent, and place the upper and lower support blocks 12 in the lower outer cylinder 7 of the press and the inner piston 6 of the press respectively. , and fix the supporting block 12 with the fastening screw 8, through leveling and centering, the anvil surfaces of the upper and lower diamond anvils 9 are parallel and completely overlapped. The sample to be tested is packaged between two diamond anvils 9 and sealed with a pre-pressed gasket 10 . The ball bearing 2 coated with lubricating oil is set on the inner piston 6 of the press, so that the upper outer cylinder 5 of the press is set on the inner piston 6 of the press and covers the ball bearing 2 . Put the rotating rod 14 in the rotating rod socket 1, and tighten the pressure screw 3. The above-mentio...

Embodiment 3

[0026] Example 3 Application of pressure and shear

[0027] The small-sized rotary diamond counter-anvil press of the present invention adopts a screw pressurizing pressurizing device, and four pressurizing screws 3 symmetrically distributed are screwed into the thread of the outer cylinder 7 under the press to push the inner piston 6 of the press. Squeeze to realize the pressurization of diamond anvil 9. The Belleville spring sheet 4 on the pressure screw 3 ensures that the loading force applied to the diamond anvil 9 is even and constant. The above process is a vertical pressurization process. Under the condition of constant vertical pressure, that is, under the condition that the pressure screw 3 maintains a certain amount of precession, the upper and lower diamond anvils 9 are relatively rotated by the rotation of the rotating rod 14, and the upper and lower diamond anvils 9 are rotated relative to each other through the rotation of the piston 6 on the top side of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com