Linear density measuring method for optical grating

A measurement method and linear density technology, applied in the field of spectroscopy, to achieve the effect of small spot size, high stability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

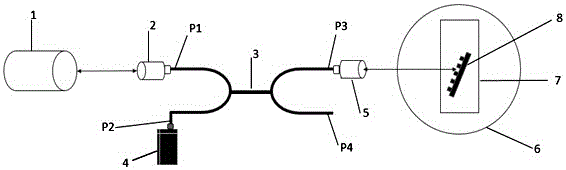

[0015] figure 1 Shown is a grating linear density measurement system provided by an embodiment of the present invention, including a laser light source 1, a fiber coupler 2, a single-mode 2x2 fiber coupler 3, a fiber optic power meter 4, a fiber collimator 5, and an electric rotary table 6. Electric linear displacement platform 7 and grating 8 to be tested.

[0016] The laser light emitted by the laser light source 1 is coupled by the fiber coupler 2 and enters the port P1 of the single-mode 2x2 fiber coupler 3. The single-mode 2x2 fiber coupler 3 has 4 ports P1, P2, P3 and P4, and the middle is the coupling section. The laser light will be transmitted from port P1 to port P3 and port P4 respectively, the part of the laser light transmitted to port P4 will be lost, and the laser light transmitted to port P3 will be irradiated to the grating to be tested 8 after being collimated by the fiber collimator 5 surface. The laser light is diffracted after hitting the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com