Method for temperature drift inhibition of constant power type thermal type gas flowmeter

A technology of thermal gas flow and temperature drift, which is applied in liquid/fluid solid measurement, thermal effect detection of fluid flow, volume measurement, etc. It can solve the problems of zero drift and measurement error increase, so as to suppress zero drift and improve measurement Effects of Accuracy and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

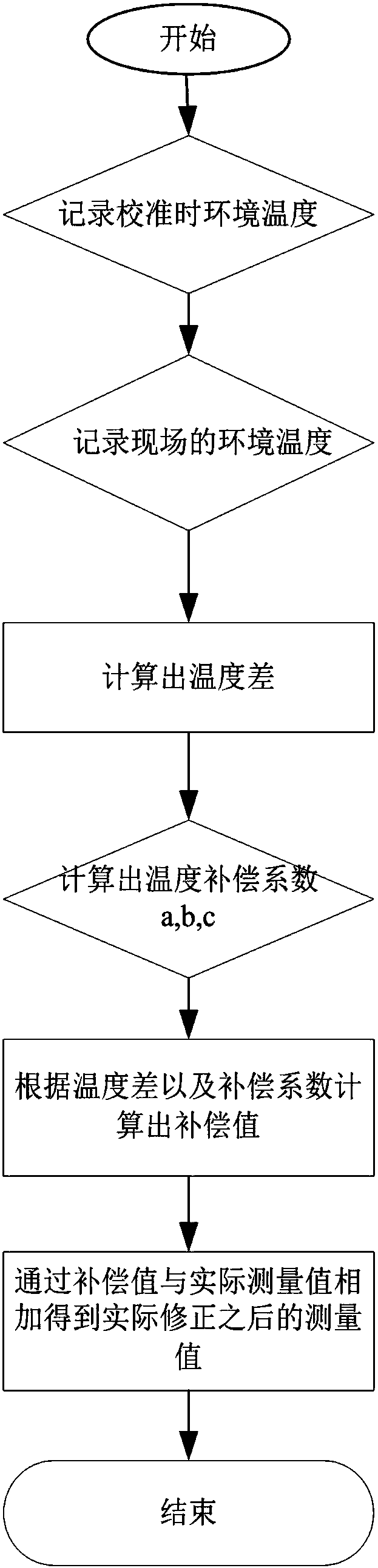

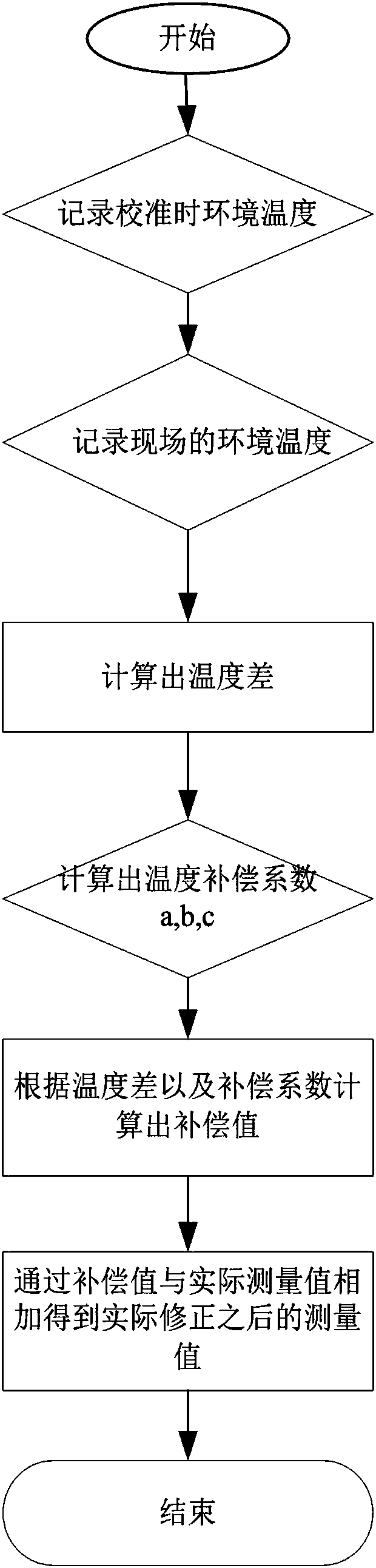

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

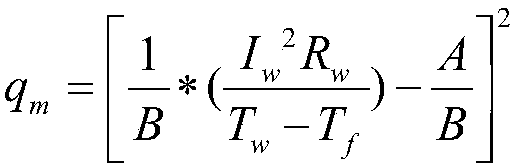

[0032] For a constant power thermal gas flowmeter, one is heated as an active element (speed probe), and the other is not heated as a reference element (temperature probe). Generally, the reference temperature value and the heating temperature value are collected at the same time, and the temperature The voltage value collected by the probe and speed probe can be expressed as:

[0033] V f = R 0 I f [1+α(T f +ΔT)]

[0034] V s = R 0 I s [1+α'(T f +T s +ΔT)]

[0035] ΔT=T c -T f

[0036] where V f The voltage value collected for the temperature probe; V s The voltage value collected for the speed probe; R 0 is the resistance value of the platinum resistor at 0°C; I f is the working current of the temperature probe; α is the temperature coefficient of the platinum resistance of the temperature probe; I s is the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com