Thickness detection device and method

A technology for thickness detection and detection electrodes, which is applied in the electromechanical field and can solve the problems of low accuracy of thickness detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, a thickness detection device is also provided, which is used to implement the above embodiments and preferred implementation modes, and what has been described will not be repeated. As used below, the term "module" may be a combination of software and / or hardware that realizes a predetermined function. Although the devices described in the following embodiments are preferably implemented in software, implementations in hardware, or a combination of software and hardware are also possible and contemplated.

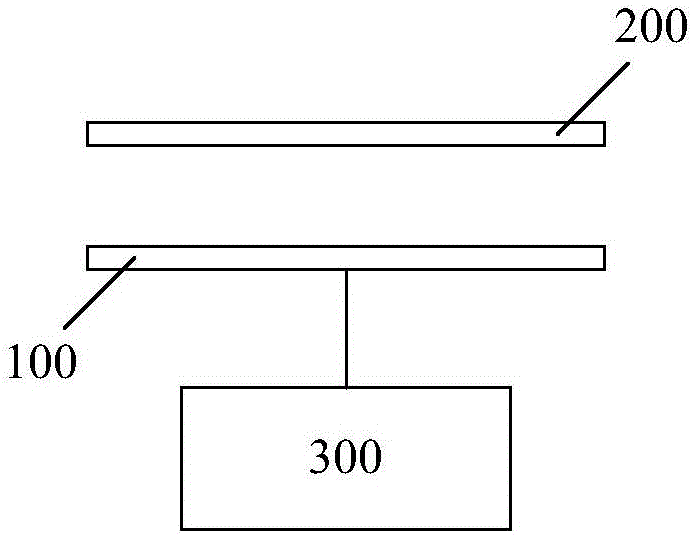

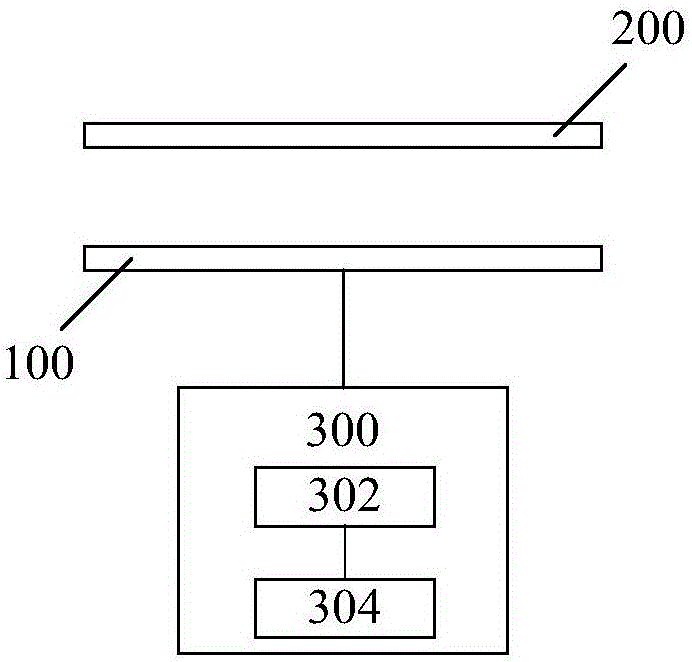

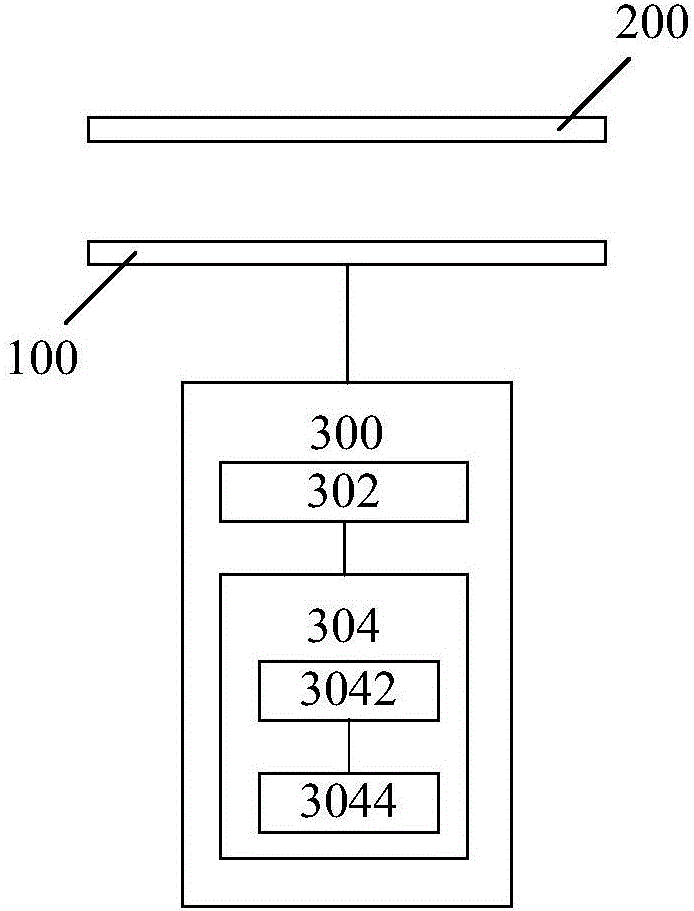

[0043] figure 1 is a structural frame of a thickness detection device according to an embodiment of the present invention Figure 1 ,Such as figure 1 As shown, the device includes:

[0044] Common electrode 100, detection electrode 200 and control unit 300;

[0045] The control unit 300 is connected to the common electrode 100, and is used to control the voltage information of the voltage applied to the common electrode 100 according to the de...

Embodiment 2

[0093] In this embodiment, a thickness detection method is provided, Figure 9 is a flowchart of a thickness detection method according to an embodiment of the present invention, such as Figure 9 As shown, the process includes the following steps:

[0094] Step S902, controlling the voltage information of the voltage applied to the common electrode according to the detection information of the film to be tested, wherein the detection information is used to indicate the characteristics of the film to be tested, and the voltage information is used to indicate the characteristics of the voltage applied to the common electrode;

[0095] Step S904, loading the voltage corresponding to the voltage information on the common electrode;

[0096] Step S906, detecting the thickness of the film to be measured according to the voltage applied on the common electrode.

[0097] Optionally, the above-mentioned thickness detection method can be applied to, but not limited to, scenarios of t...

Embodiment 3

[0117] Through the description of the above embodiments, those skilled in the art can clearly understand that the method according to the above embodiments can be implemented by means of software plus a necessary general-purpose hardware platform, and of course also by hardware, but in many cases the former is better implementation. Based on such an understanding, the essence of the technical solution of the present invention or the part that contributes to the prior art can be embodied in the form of software products, and the computer software products are stored in a storage medium (such as ROM / RAM, disk, CD) contains several instructions to enable a terminal device (which may be a mobile phone, a computer, a server, or a network device, etc.) to execute the methods described in various embodiments of the present invention.

[0118] The embodiment of the invention also provides a storage medium. Optionally, in this embodiment, the above-mentioned storage medium may be conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com