Reflecting cover of energy saving lamp

A technology for reflectors and energy-saving lamps, which is applied in the direction of lampshades, reflectors, and components of lighting devices. It can solve problems such as the inability to adjust reflectors, and achieve the effects of improving light-gathering performance, improving light-gathering performance, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

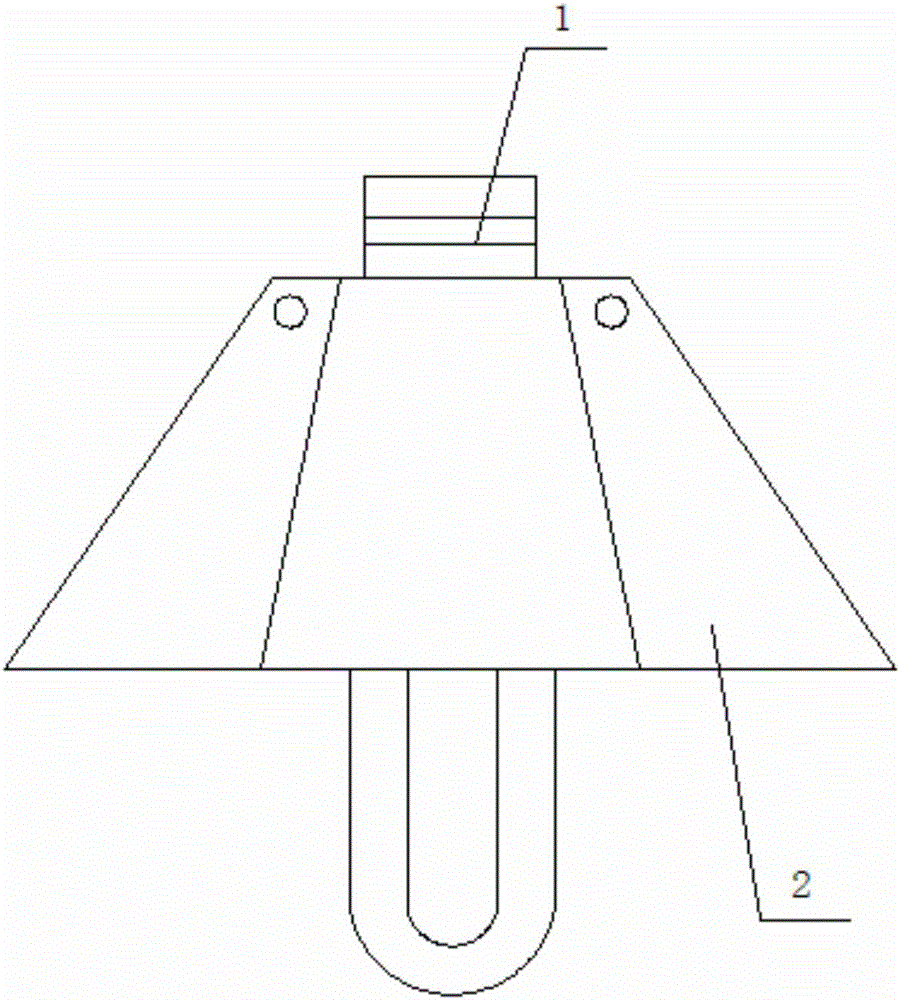

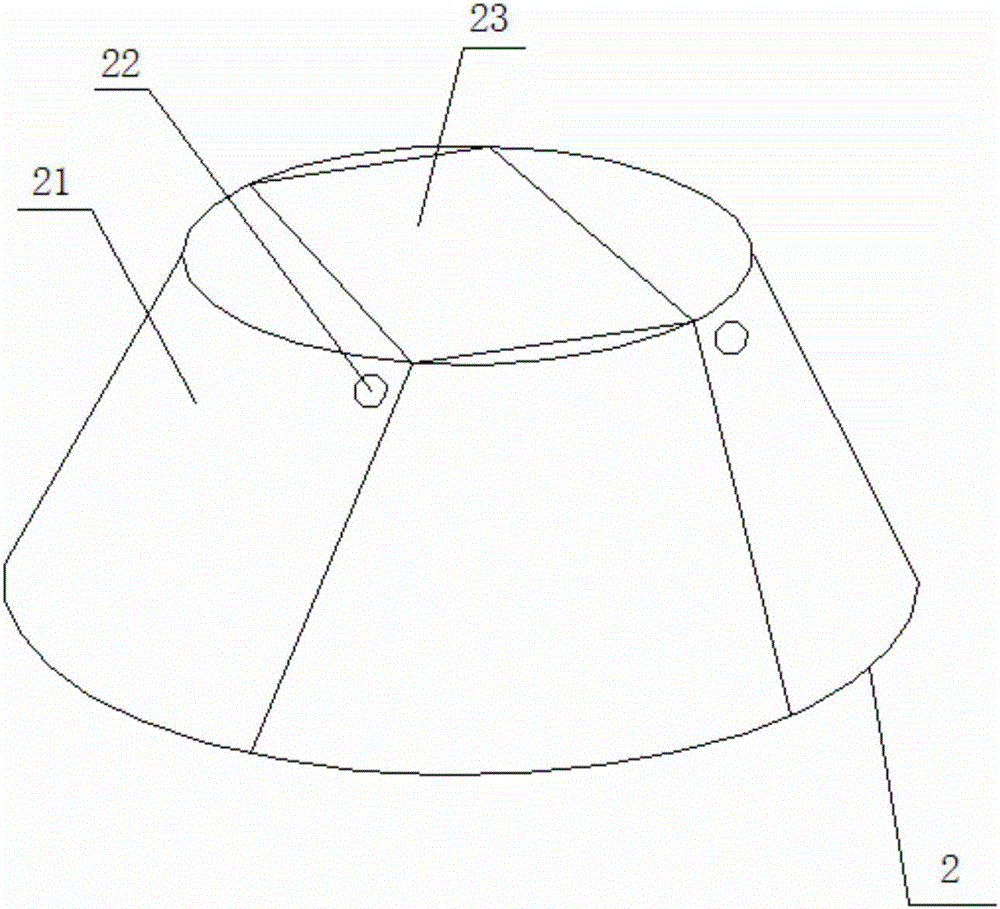

[0028] Such as Figure 1 to Figure 2 As shown, the present invention provides an energy-saving lamp, comprising: a lamp body 1 and a reflector 2 covering the lamp body 1; the reflector 2 includes four cover bodies 21 distributed along the circumference; the top of the cover body 21 is provided with a rotating The shaft 22; the tops of the four cover bodies 21 enclose an installation opening 23; the lamp body 1 is arranged in the installation opening 23. The material of the rotating shaft 22 is metal. During use, the user can adjust the angle of the cover body 21 according to the needs of different situations, so that the cover body 21 can rotate around the rotation axis 22, so as to obtain different light-gathering effects and meet the needs of users.

Embodiment 2

[0030] The reflector forming material for energy-saving lamps is made of the following raw materials in parts by weight:

[0031] 20 parts of polyvinyl chloride, 5 parts of xylene, 10 parts of isopropanol, 20 parts of polycarbonate, 20 parts of polymethyl methacrylate, 10 parts of light scattering masterbatch, 10 parts of carboxymethyl cellulose, 5 parts of stone Phinethine A.

[0032] The preparation method of the reflector molding material for energy-saving lamps has the following steps:

[0033] ①Add 20 parts of polyvinyl chloride and 5 parts of xylene into the reaction kettle according to parts by weight, and stir for 5 minutes at a speed of 1500r / min;

[0034] ② Add 10 parts of isopropanol, 20 parts of polycarbonate, and 20 parts of polymethyl methacrylate to the reactor in order by weight, adjust the speed of the reactor to 1500r / min, and stir for 5 minutes;

[0035] ③ Add 10 parts of light-scattering masterbatch, 10 parts of carboxymethyl cellulose, and 5 parts of hup...

Embodiment 3

[0037] The reflector of the energy-saving lamp includes four cover bodies distributed along the circumference; the top of the cover body is provided with a rotating shaft; the top of the four cover bodies encloses a mounting opening, and the cover body is made of reflector molding materials for energy-saving lamps. become.

[0038] A method for manufacturing a reflector of an energy-saving lamp, the steps are as follows:

[0039] 1. Extrusion and granulation: put the reflector molding material for energy-saving lamps (prepared in Example 2) into the screw extruder, carry out melt blending, extrusion, cooling, granulation, and the blending and extrusion of the screw extruder Temperature: Zone 1 170°C, Zone 2 180°C, Zone 3 190°C, Zone 4 205°C, Zone 5 215°C, Head 220°C; Screw speed 200r / min;

[0040] ②, injection molding processing: put the particles manufactured in step ① into the injection molding machine, and perform conventional injection molding processing to obtain an arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com