Shear-stress-resisting flange butt joint device

A docking device and anti-shear technology, applied in the direction of fixing devices, mechanical equipment, etc., can solve problems such as poor shear resistance, and achieve the effect of improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below by means of examples, but the following examples are only illustrative, and the protection scope of the present invention is not limited by the examples.

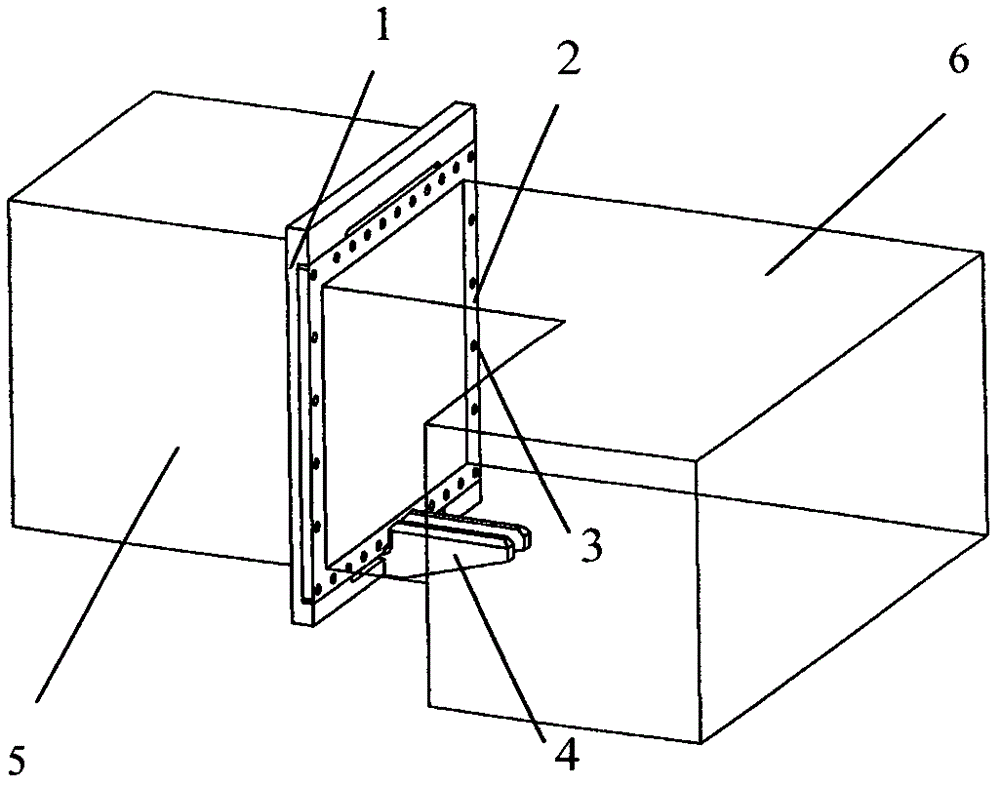

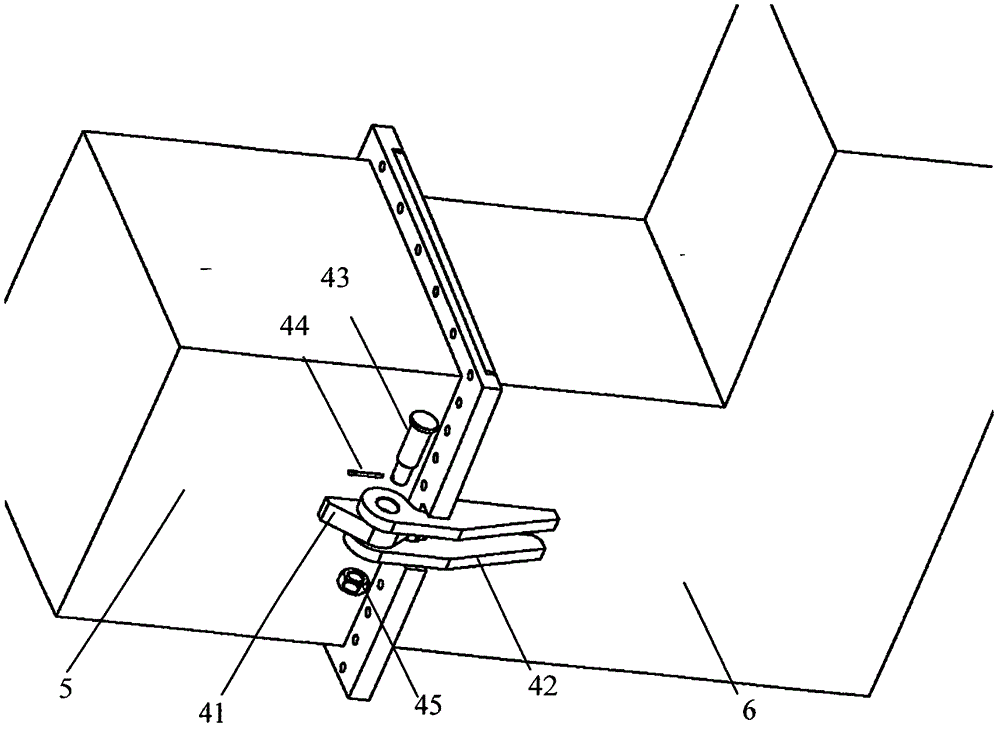

[0015] Such as figure 1 As shown, a shear stress-resistant flange butt joint device includes: flange I (1), flange II (2), bolt fasteners (3), safety device (4), connecting body (5 ), linker (6). Flange I(1) and flange II(2) are both square plate-shaped, and there are opening slots in the lower middle of flange I(1) and flange II(2), and flange I( 1) There is a transverse through groove (11) in the middle of the docking surface with the flange II (2), the height of the groove (11) is consistent with the height of the flange II (2), and the depth of the groove (11) is the same as The thickness of the flange II(2) is the same, the groove (11) and the flange II(2) have a clearance fit; there are bolt connection holes around the flange I(1) and flange II(2); The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com