Shock isolation support with servo shock isolation system

A technology of shock-isolation support and shock-isolation system, which is applied in the direction of shockproof, building components, buildings, etc., can solve the problems that the working frequency cannot be changed, cannot meet the requirements of shock isolation, and the effect of shock isolation is weakened, so as to achieve difficult resonance and simple structure , mechanical and electromechanical performance stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

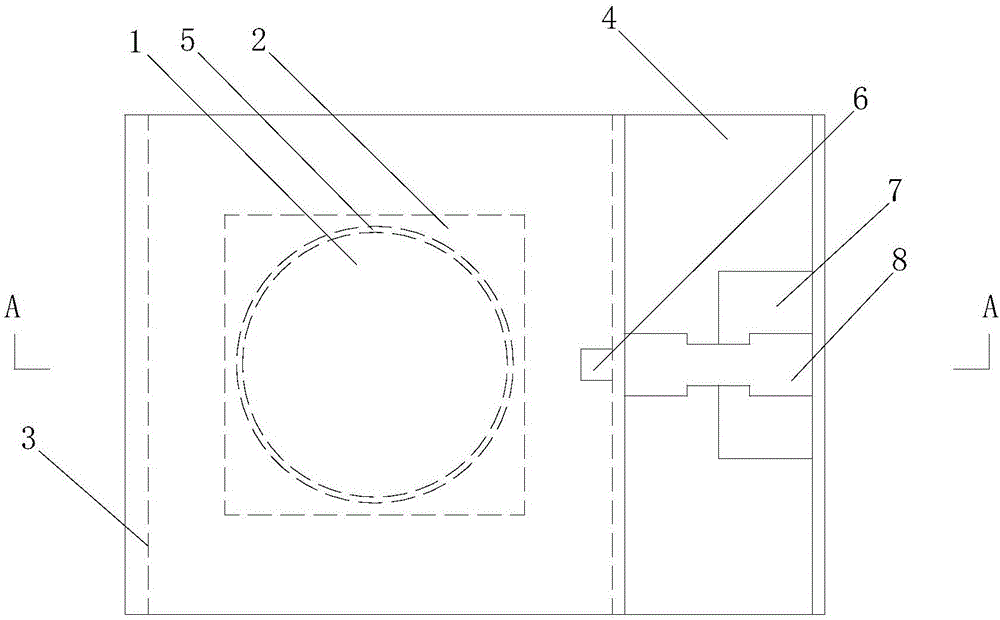

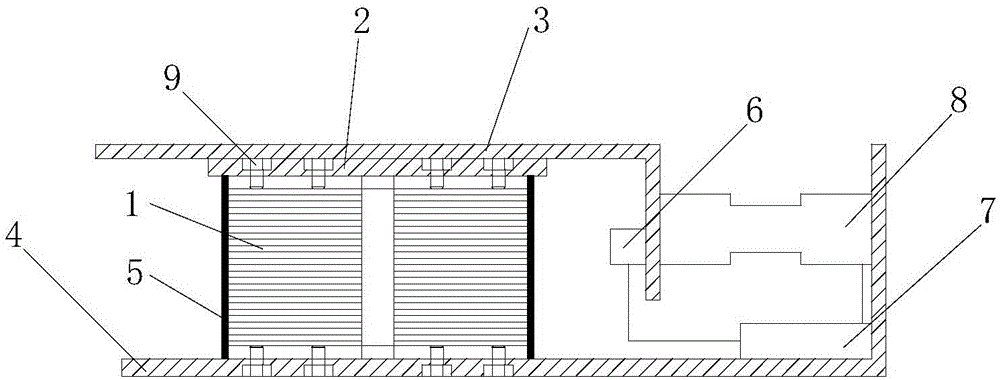

[0013] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0014] Such as Figure 1-2 A vibration isolation bearing with a servo vibration isolation system shown includes a laminated rubber bearing 1, the outer surface of the laminated rubber bearing 1 is covered with a bearing protective sleeve 5, and the upper and lower sides of the laminated rubber bearing 1 The upper flange plate 2 and the lower flange plate 4 are respectively connected by connecting bolts 9; the upper surface of the upper flange plate 2 is fixedly connected with the upper cover plate 3, and the lower flange plate 4 is installed with a A servo control system for self-adaptive adjustment of the shock-isolation bearing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com