Preparation method of fermented parochetus communis perfumes for cigarettes

A gorse tobacco, fermented technology, applied in the field of preparation of fermented gorse tobacco spices, to achieve the effects of increasing aroma and aftertaste, reducing miscellaneous gas and irritation, and cleaning the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

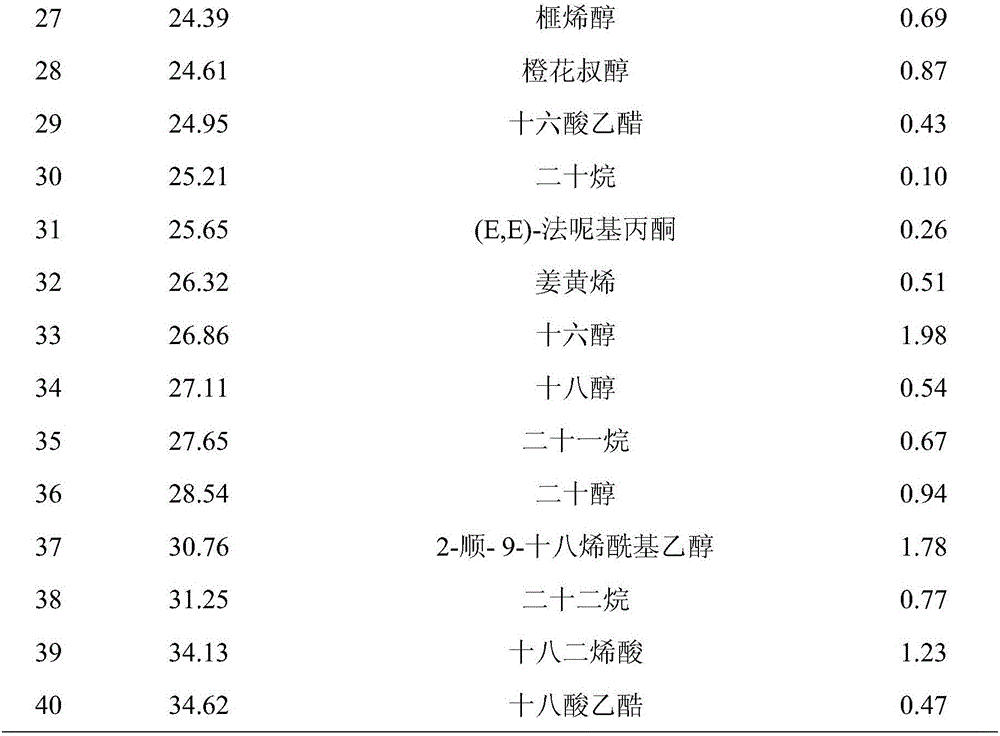

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation method of described a kind of fermented gorse tobacco spices is characterized in that concrete steps are as follows:

[0024](1) Weigh 100g of gorse, put it into a 500ml Erlenmeyer flask, add water according to the ratio of raw materials and water 1:2, sterilize at 121°C for 5-10min, cool to room temperature, adjust the pH value to 4.5-7.0 , add 1% cellulase and 1% glucoamylase of the weight of gorse, react for 4 hours at a temperature of 50°C and a constant temperature shaker with a rotating speed of 100-200r / min, and then adjust the pH value to 3.0-6.0. React for 2 hours in a constant temperature shaker at 40°C with a rotation speed of 100-200r / min;

[0025] (2) add 3% glucose of gorse enzymolysis solution weight in above-mentioned gorse enzymolysis solution, 0.5% ammonium sulfate, 0.3% magnesium sulfate heptahydrate, 0.5% sodium chloride, 0.1% ferrous sulfate heptahydrate , sterilized at 115°C for 5-15 minutes;

[0026] (3) Inoculate t...

Embodiment 2

[0028] Embodiment 2: the preparation method of described a kind of fermented gorse tobacco spices is characterized in that concrete steps are as follows:

[0029] (1) Weigh 100g of gorse, put it into a 500ml Erlenmeyer flask, add water according to the ratio of raw materials and water 1:1, sterilize at 121°C for 8min, cool to room temperature, adjust the pH value to 4.5-7.0, add 1.5% cellulase and 0.5% glucoamylase based on the weight of gorse, reacted in a constant temperature shaker with a temperature of 60°C and a rotation speed of 100-200r / min for 2h, then adjusted the pH value to 3.0-6.0, , react in a constant temperature shaker with a rotation speed of 100-200r / min for 3h;

[0030] (2) add 5% glucose in the gorse hydrolyzate in step (1), 0.8% ammonium sulfate, 0.5% magnesium sulfate heptahydrate, 0.3% sodium chloride, 0.12% ferrous sulfate heptahydrate, at 115 Sterilize at ℃ for 10 minutes;

[0031] (3) Inoculate the activated strain into the pretreated enzymolysis sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com