A kind of two-component concrete interface adhesive and using method thereof

A technology of concrete and interface adhesive, applied in the directions of adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the problems of interface damage, low bonding strength, unsatisfactory bonding effect, etc., and achieve long application time. , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

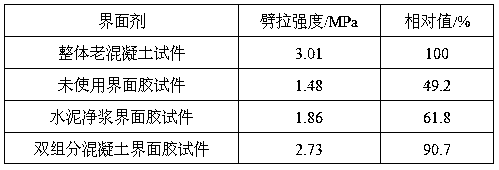

Embodiment 1

[0017] A two-component concrete interface adhesive, which is composed of agent A and agent B in a weight ratio of 3:1, wherein agent A is made of the following components by weight: bisphenol A epoxy resin E44 100 kg , furfural 30 kg, dibutyl phthalate 10 kg; agent B is made of the following components by weight: bisphenol A epoxy resin E44 100 kg, diethylenetriamine 120kg, phenol 2 kg, acetone 150 kg kg, ethanol 20 kg.

[0018] The preparation method of above-mentioned two-component concrete interface adhesive comprises the following steps:

[0019] (1) Preparation of Agent A system: Weigh each component of Agent A system by weight, stir and mix at 45°C, then cool to room temperature to obtain Agent A system;

[0020] (2) Preparation of agent B system: Weigh each component of agent B system by weight, add diethylenetriamine into a three-necked flask with a stirrer, heat to 75°C and keep the temperature, slowly add 45 Bisphenol A type epoxy resin E44 preheated at ℃, stirred ...

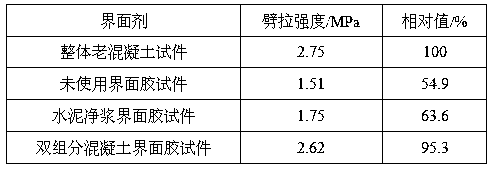

Embodiment 2

[0032] A two-component concrete interface adhesive, which is composed of agent A and agent B in a weight ratio of 3:1, wherein agent A is made of the following components by weight: bisphenol A epoxy resin E44 100 kg , furfural 35 kg, dibutyl phthalate 8 kg; agent B is made of the following components by weight: bisphenol A type epoxy resin E44 100 kg, diethylenetriamine 140kg, phenol 6 kg, acetone 170 kg kg, ethanol 10 kg.

[0033] The preparation method of above-mentioned two-component concrete interface adhesive comprises the following steps:

[0034] (1) Preparation of Agent A system: Weigh each component of Agent A system by weight, stir and mix at 45°C, then cool to room temperature to obtain Agent A system;

[0035] (2) Preparation of agent B system: Weigh each component of agent B system by weight, add diethylenetriamine into a three-necked flask with a stirrer, heat to 75°C and keep the temperature, slowly add 45 Bisphenol A type epoxy resin E44 preheated at ℃, stir...

Embodiment 3

[0047] A two-component concrete interface adhesive, which is composed of agent A and agent B in a weight ratio of 3:1, wherein agent A is made of the following components by weight: bisphenol A epoxy resin E44 100 kg , furfural 40 kg, dibutyl phthalate 5 kg; agent B is made of the following components by weight: bisphenol A type epoxy resin E44 100 kg, diethylenetriamine 115kg, phenol 2 kg, acetone 200 kg kg, ethanol 15 kg.

[0048] The preparation method of above-mentioned two-component concrete interface adhesive comprises the following steps:

[0049] (1) Preparation of Agent A system: Weigh each component of Agent A system by weight, stir and mix at 45°C, then cool to room temperature to obtain Agent A system;

[0050] (2) Preparation of agent B system: Weigh each component of agent B system by weight, add diethylenetriamine into a three-necked flask with a stirrer, heat to 75°C and keep the temperature, slowly add 45 Bisphenol A type epoxy resin E44 preheated at ℃, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com