A high-barrier composite film

A high-barrier, composite film technology, applied in the field of packaging materials, can solve problems such as film material aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

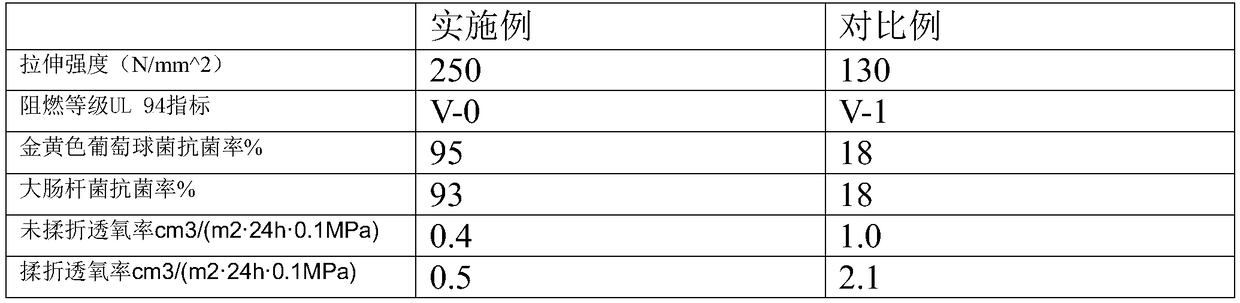

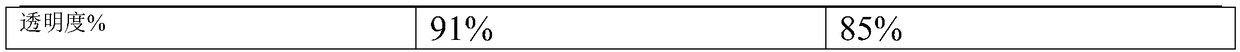

Examples

Embodiment

[0055] A high-barrier composite film, adding PP plastic particles and PET plastic particles to a co-extrusion cast film machine to make a PET / PP film including a PET layer and a PP layer,

[0056] The PP plastic particles comprise the following components by weight:

[0057] PP: 120 parts, trihydroxypolyoxypropylene ether: 25 parts, N, N'-(4,4'-methylenediphenyl) bismaleimide: 5 parts, trimethylolpropane triacrylic acid Methyl ester: 15 parts, 4,4'-dihydroxydiphenyl sulfide: 8 parts, montmorillonite: 8 parts, paraffin wax: 10 parts, antioxidant 1010: 0.2 parts, nano-TiO2: 2 parts, polyether siloxane Alkane copolymer: 0.5 parts, methyl hydroxyethyl cellulose: 0.5 parts, vinyl triperoxy tert-butylsilane: 1 part;

[0058] Described PET plastic particle comprises following composition by weight:

[0059] Terephthalic acid: 1000 parts; Ethylene glycol: 600 parts; 2-nitroterephthalic acid-4-methyl ester: 10 parts, maleic anhydride: 50 parts, 2-methyl-2,4- Pentylene glycol: 5 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com