Alkali-activated cementing material and preparation method thereof

A cementitious material, alkali-activated technology, applied in cement production, etc., can solve problems such as blooming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The method for preparing an alkali-activated gelling material provided by an embodiment of the present invention includes the following steps:

[0040] (1) Weigh the raw materials: the raw materials include powder, an aqueous solution of a liquid activator, and aluminum-containing additives, wherein the powder is calcined bauxite tailings and slag powder in a mass ratio of 7-8 :3-2 is mixed, the aqueous solution of the liquid stimulant is Na 2 O mass is calculated as 4-5% of the mass of the powder, according to Na 2 Calculate the mass of O and weigh the mass of aluminum-containing additives. 2 O and Al 2 O 3 The molar ratio is 0.9-1.3:1;

[0041] (2) Mixing the powder and aluminum-containing additives to obtain a solid raw material, and mixing the solid raw material and an aqueous solution of a liquid activator to obtain the alkali-activated gelling material;

[0042] The mass ratio of water in the raw material to the solid raw material is 0.4-0.5.

[0043] The above scheme has...

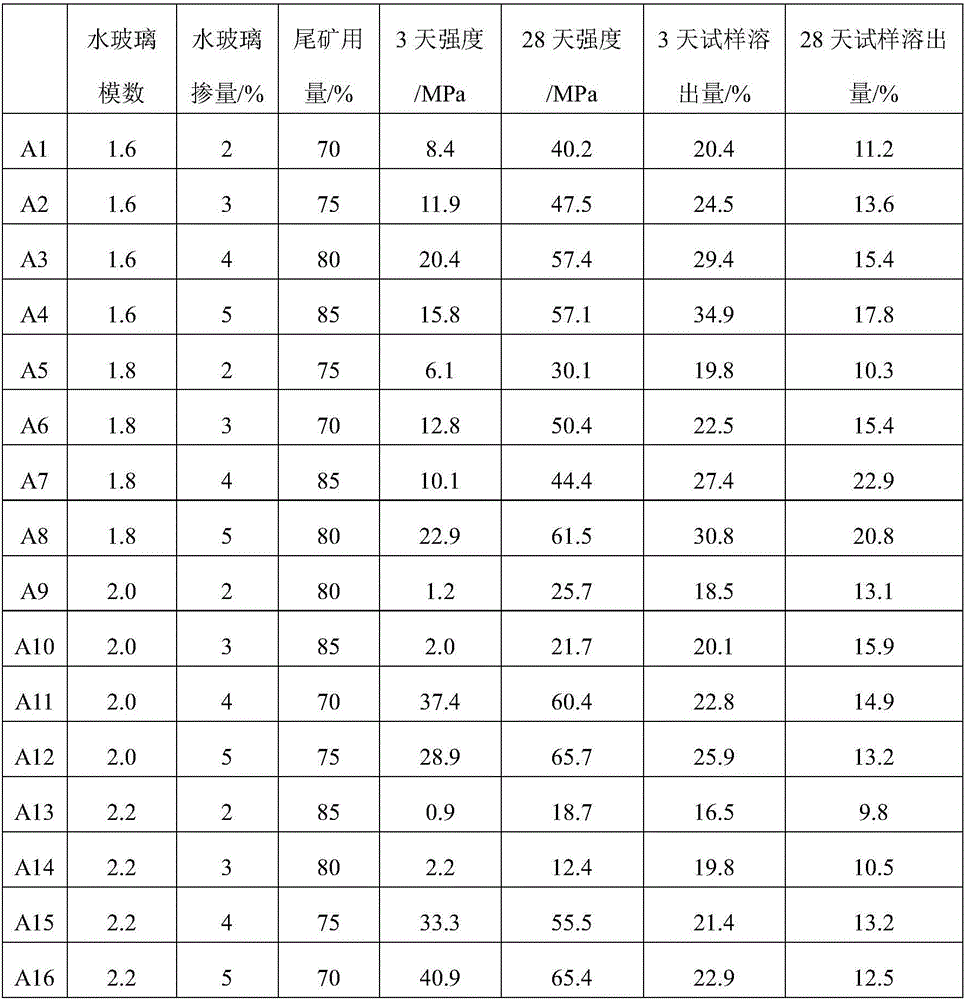

Embodiment 1

[0051] Table 4 shows the alkali dissolution amount and strength of the sample after mixing with aluminum-rich metakaolin. The cementing material ratio is 70% tailings + 30% slag powder + 5% water glass (with Na 2 O, accounting for the mass percentage of tailings and slag powder; modulus is 2.2)

[0052] Table 4

[0053]

[0054] It can be seen from the results that the addition of metakaolin brings more aluminum, which gradually reduces the Si / Al ratio and Na / Al ratio of the sample, and even makes the Na / Al ratio close to 1. Assuming that the aluminum in metakaolin can be released under the condition of alkali excitation, and all enter the silicon-aluminum polymer structure, then the excess negative charge in the structure will be bonded to Na + To achieve equilibrium, the amount of alkali dissolution is reduced accordingly. However, the fact is quite the opposite. The amount of alkali dissolution of the sample after the addition of metakaolin increases, and the strength gradually...

Embodiment 2

[0061] According to the results of Example 1, it can be seen that whether aluminum is released quickly is one of the keys to whether the blended components can inhibit the alkali dissolution. Therefore, soluble aluminate can be used at room temperature to achieve the purpose of rapid release of aluminum. Since calcium is required for gel formation, calcium aluminate can be used. Among several kinds of calcium aluminate, monocalcium aluminate has hydration activity and is the main component of aluminate cement. Therefore, aluminate cement can be used as a modified component at room temperature.

[0062] Table 6 shows the inhibitory effect of adding a small amount of aluminate cement to the alkali dissolution of cementitious materials. The cementing material ratio is 70% tailings + 30% slag powder + 5% water glass (with Na 2 O, accounting for the mass percentage of tailings and slag powder; modulus is 2.2)

[0063] Table 6

[0064]

[0065] It can be seen from the results that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com