Glitter luminous thermal transfer carbon ribbon and preparation method thereof

A photothermal and carbon ribbon technology, applied in printing, ink ribbon, luminous coating, etc., can solve the problems of development and production gaps, etc., and achieve strong scratch resistance, good transferability and optical recognition, and good promotion and application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Preparation of heat resistant back coat:

[0059] Mix and stir the modified silicone resin and butanone evenly (mass ratio, resin: butanone = 2:8), use a gravure coater, coat one side of the base film, dry at 110°C, and coat The amount is generally controlled at 0.01~0.2g / m 2 (Refer to each embodiment for the specific coating amount).

[0060] Preparation of release layer:

[0061] The material wax in the release layer is dissolved by heating, and the binder is put in in the form of an intermediate. After the dissolution is complete, add luminous powder, disperse evenly at high speed, and keep warm at 95°C~105°C for standby. Using a gravure coater, the material is uniformly coated on the other side of the base film at 90°C~100°C, dried at 40°C, and the thickness is controlled at 1.4~1.8µm (see the specific thickness in each example).

[0062] Preparation of magnetic ink layer:

[0063] Except for the glitter powder, the materials in the ink layer are dissolved with ...

Embodiment 1~9

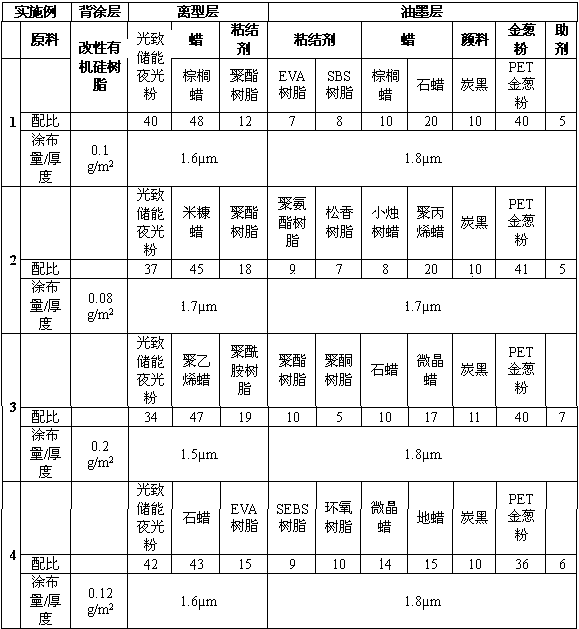

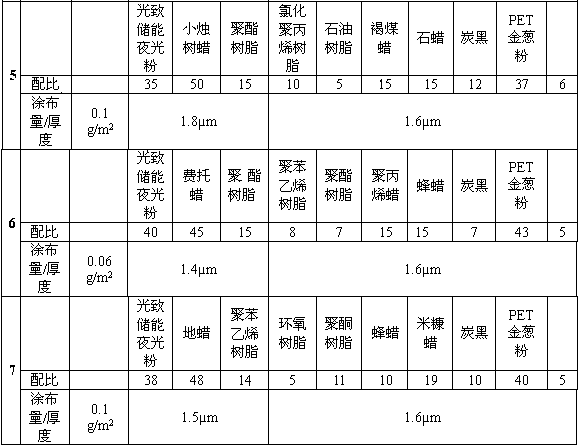

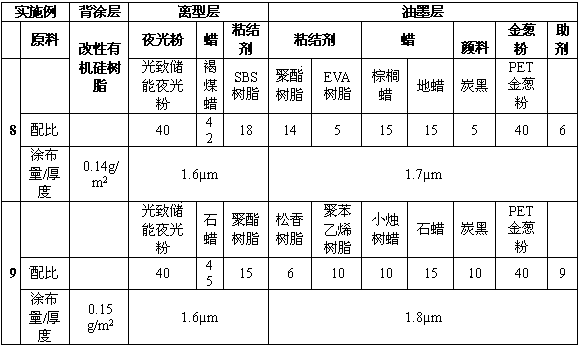

[0065] The specific material proportioning situation in each embodiment is shown in the table below.

[0066]

[0067]

[0068]

[0069] In order to prove that the ratio of each material provided by the present invention is an optimized technical solution, the inventor deliberately set up the following comparative examples as a comparison, specifically as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com