A high temperature resistant radar infrared compatible stealth material based on double-layer metamaterial and its preparation method

A stealth material and metamaterial technology, applied in the field of high temperature resistant radar infrared compatible stealth materials and their preparation, can solve the problem of not fully considering the coupling effect of the frequency selective surface and the wave absorbing structure, poor broadband and low frequency wave absorption performance, and difficult to apply high temperature environment and other problems, to achieve the effect of solving contradictory problems, good broadband absorbing performance, and good low emissivity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

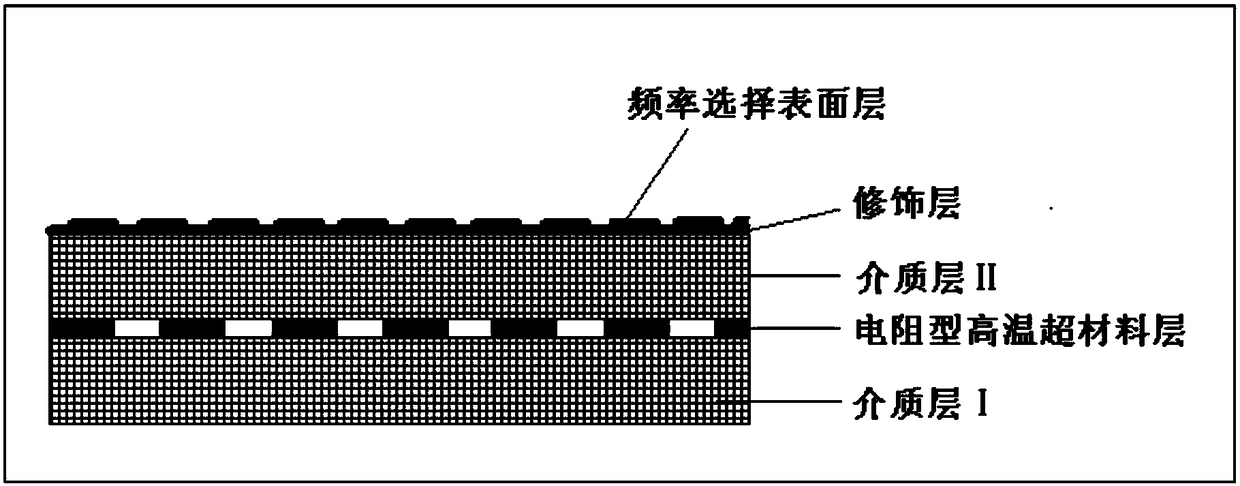

[0053] A kind of high temperature resistant radar infrared compatible stealth material based on double-layer metamaterial of the present invention, its structural diagram is as follows figure 1 As shown, it is a layered structure, which includes dielectric layer Ⅰ, resistive high-temperature metamaterial layer, dielectric layer Ⅱ, modification layer and frequency selective surface layer from the inner to the outer surface; wherein, the thickness of the dielectric layer Ⅰ is 3 mm, and the dielectric layer The thickness of II is 1mm, and the dielectric layer I and II are both made of continuous aluminosilicate fiber reinforced mullite-based composite materials; the resistive high-temperature metamaterial layer is mainly composed of a periodic pattern of high-temperature resistant resistive coating (two Ruthenium oxide-based glass-based resistance coating), the periodic pattern of the high-temperature-resistant resistance coating is a square patch pattern distributed in a square a...

Embodiment 2

[0068] A kind of high temperature resistant radar infrared compatible stealth material based on double-layer metamaterial of the present invention, its structural diagram is as follows figure 1As shown, it is a layered structure, which includes dielectric layer Ⅰ, resistive high-temperature metamaterial layer, dielectric layer Ⅱ, modification layer and frequency selective surface layer from the inner to the outer surface; wherein, the thickness of the dielectric layer Ⅰ is 2.8mm, and the dielectric layer The thickness of layer II is 1.7 mm. Both dielectric layer I and dielectric layer II are made of continuous aluminosilicate fiber-reinforced alumina-based composite materials; the resistive high-temperature metamaterial layer is composed of a periodic pattern of high-temperature-resistant resistive coating (two Ruthenium oxide-based glass-based resistance coating), the periodic pattern of the high-temperature-resistant resistance coating is a square-distributed circular patch p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com