Gluing and assembly all-in-one machine of LED wall washing lamp

A technology of LED wall washer and all-in-one machine, which is applied to the device for coating liquid on the surface, metal processing, metal processing equipment, etc. High waterproof and dustproof effect, good sealing effect, uniform effect of finished rubber strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

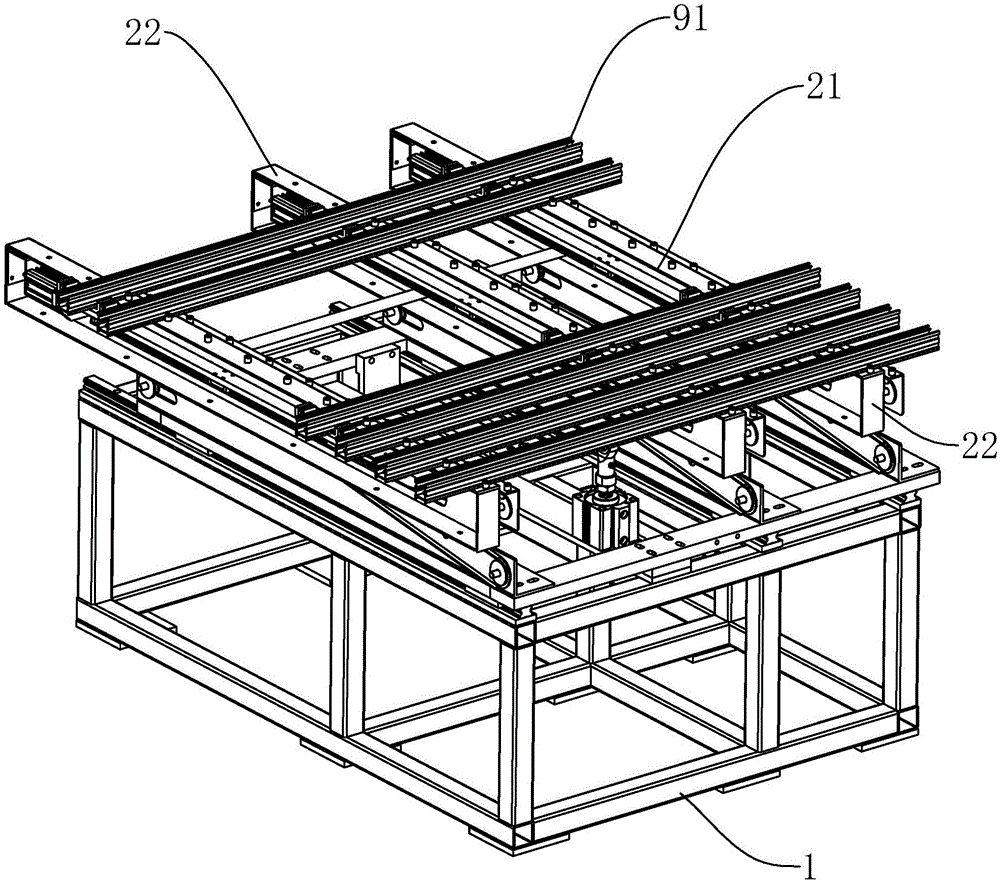

[0053] refer to Figure 1 to Figure 18 , Figure 1 to Figure 18 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, an all-in-one machine for gluing and assembling an LED wall washer includes a frame 1, a feeding mechanism 2, a gluing mechanism 5, a trough mechanism 3, and a grabbing mechanism. Mechanism 4, wherein, the gluing mechanism 5 and the grabbing mechanism 4 are all manipulator devices, and are arranged on a stand 41, and the frame 1 is provided with a workbench 11, and the stand 41 is arranged on the workbench 11 .

[0054] The feeding mechanism 2 is arranged on the frame 1 and is used to transport the wall washer frame 91. On the workbench 11, along the conveying direction of the feeding mechanism 2, a gluing station and a cover station are respectively arranged. The feeding mechanism 2. The frame body 91 of the wall washer can be transported to the gluing station and the cover station in sequence.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com