Plastic shell structure and preparation method thereof

A technology of plastic shell and plastic shell, which is applied in the structural form of radiating elements, antenna support/mounting device, radiating unit cover, etc., which can solve the problems of poor overall effect, fashion and novelty, limited space in 5G antenna structure and design, and yield rate Low-level problems, to achieve the effect of gorgeous appearance decoration, fashionable and novel decoration, and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

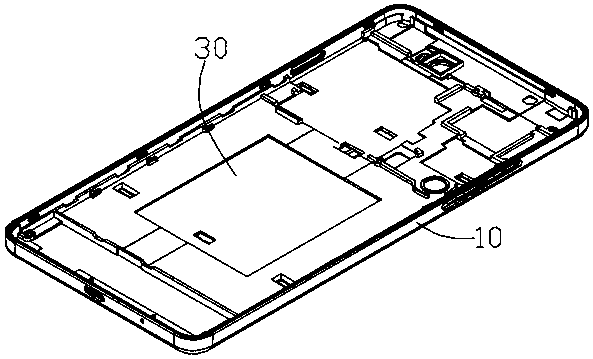

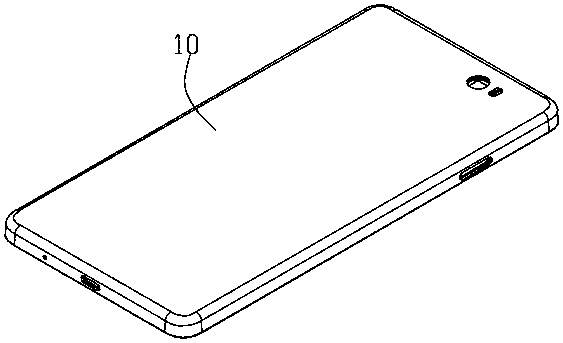

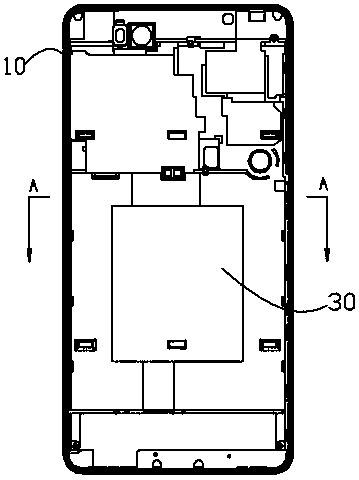

[0087] refer to Figure 1-5 , a plastic shell structure, including a plastic shell 10, a PET composite decorative film 20 attached to the inner surface of the plastic shell 10, the side of the PET composite decorative film that is bonded to the plastic shell is a bonding surface , the side of the PET composite decorative film away from the plastic shell is a decorative surface; the decorative surface of the PET composite decorative film 20 is provided with an LDS antenna 30 . The area of the decorative surface of the PET composite decorative film 20 except the LDS antenna contact is also injection-molded with a plastic shell functional structure 40 for electronic products. A ring sealing structure 50 is also provided on the outer periphery of the plastic shell structure.

[0088] refer to Figure 6-13 , a method for preparing a plastic shell structure, comprising the following steps:

[0089] 1) Plastic shell preparation steps: provide a plastic shell;

Embodiment approach

[0090] In the step of preparing the plastic shell in this embodiment, as a preferred implementation, the manufacturing method of the plastic shell is as follows:

[0091] Injection molding steps: refer to Figure 6 , install the compression injection mold on the compression injection molding machine, and perform compression injection molding. When molding, the cavity corresponding to the product on the mold is closed to 1.3-1.6 times the volume of the plastic product, and the volume of the plastic product is injected at 1.05 times -1.2 times. The plastic material to the cavity, and then use the compression function of the compression injection molding machine to squeeze the cavity through the clamping pressure of the injection molding machine for secondary mold closing, completely close the cavity to 100%, and squeeze the plastic raw material to fill the entire mold. cavity and pressurize the excess plastic raw material to the overflow port of the mold to obtain a molded plast...

Embodiment 2

[0166] The characteristic of this embodiment is: in the preparation step of the plastic shell, the plastic material is a modified high-fluidity plastic material mixed with high-hardness PC or high-hardness PMMA+PC.

[0167] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com