punching machine

A punching machine and punching die technology, which is applied in the field of punching machines, can solve the problems of split punching machine structure and complex oil circuit, etc., and achieve the effects of reducing volume, reducing the probability of oil leakage, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

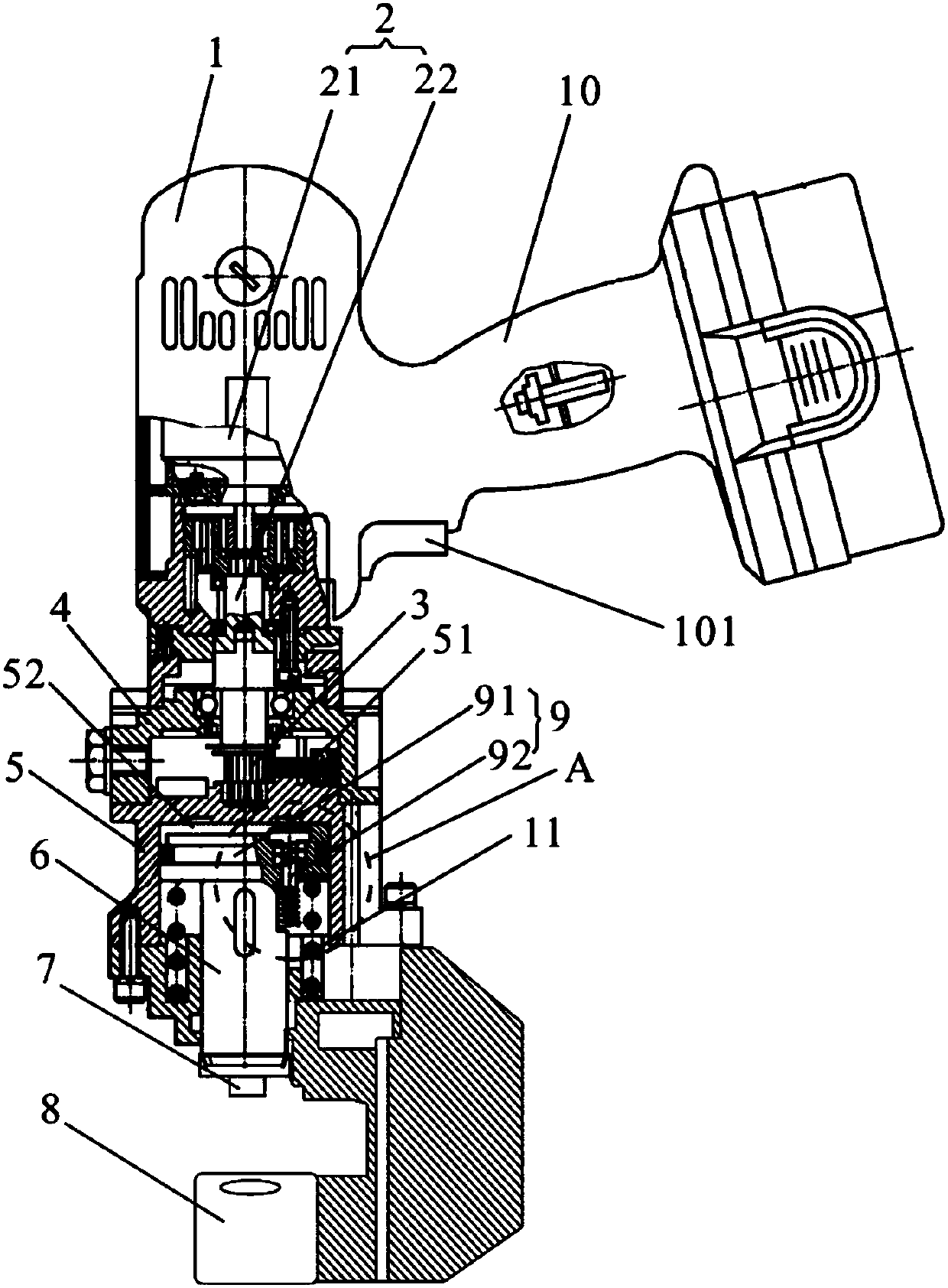

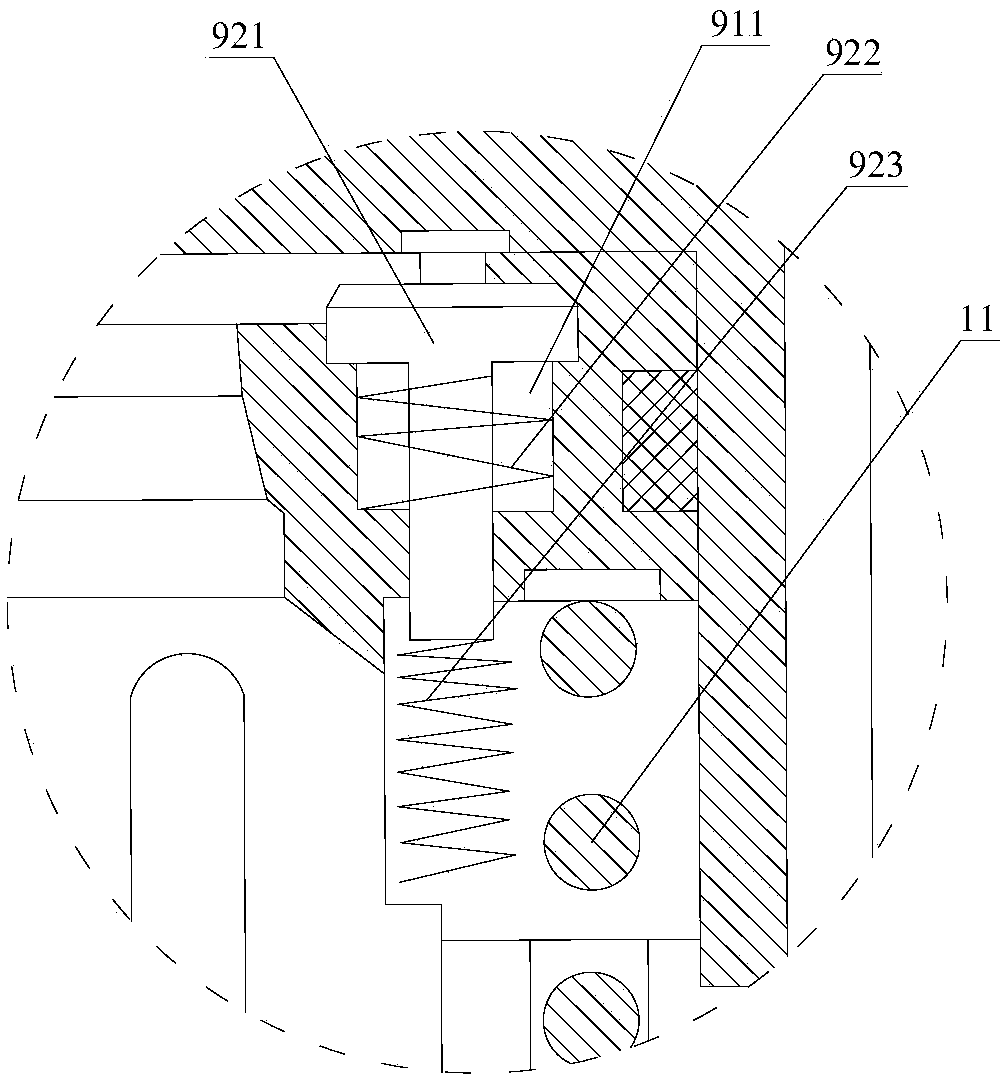

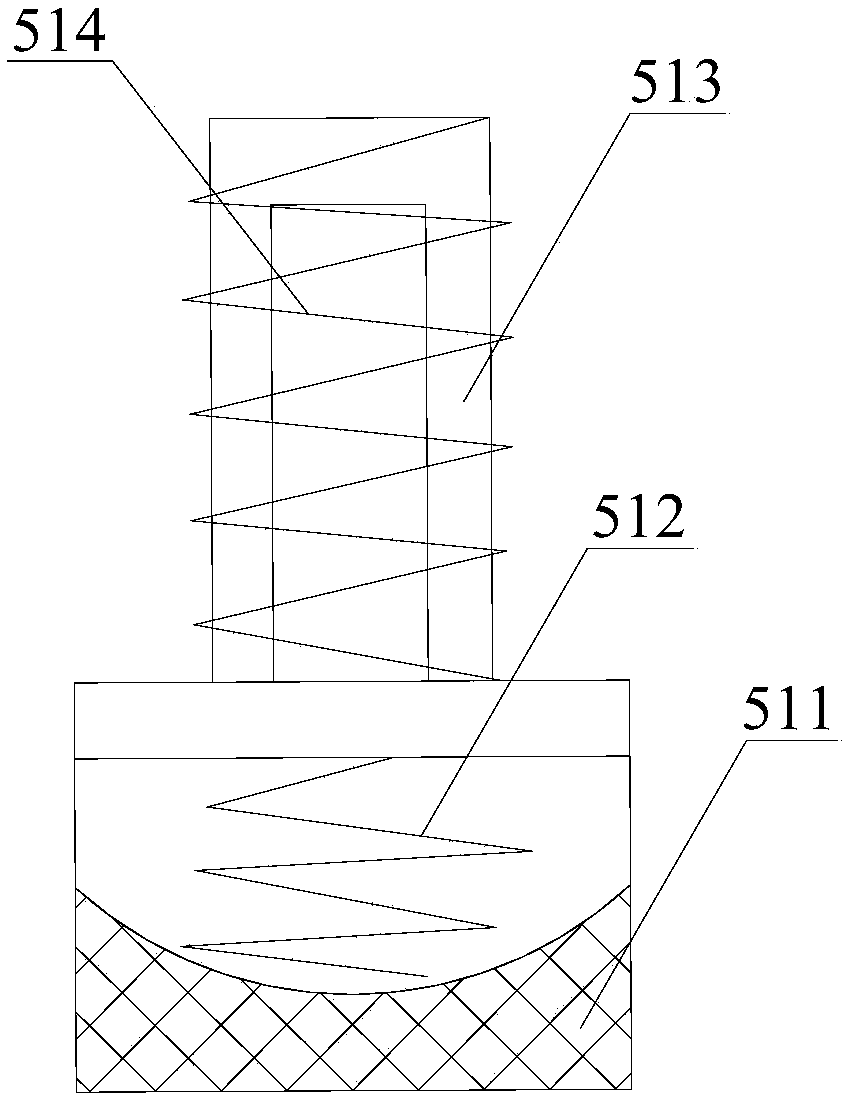

[0020] Such as figure 1 As shown, the punching machine provided in this embodiment includes a housing 1 , a drive assembly 2 , an eccentric shaft 3 , an oil cylinder 4 , a hydraulic pump 5 , a push shaft 6 , an upper die 7 , a lower die 8 and an oil return assembly 9 . The driving assembly 2 is arranged in the casing 1 . The eccentric shaft 3 is connected to the drive assembly 2 . The oil cylinder 4 is arranged in the casing 1 . The hydraulic pump 5 includes a plurality of piston assemblies 51 arranged in the circumferential direction of the eccentric shaft 3, each piston assembly 51 has a plurality of oil holes communicating with the oil cylinder 4 (due to the problem of angle, the figure is not shown), the eccentric shaft 3 The rotation drives the multiple piston assemblies 51 to move in a direction perpendicular to the axis of the eccentric shaft, squeezing the oil in the oil cylinder 4 into the oil chamber 52 of the hydraulic pump 5 . The push shaft 6 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com