Process for preparing dendrobium officinale freeze-dried powder

A technology of Dendrobium officinale and preparation process, which can be used in freeze-drying transportation, medical preparations containing active ingredients, powder transportation, etc., can solve the problems of insufficient development of new products, insufficient deep-processed products, etc., and achieve biological activity retention and scientific steps. Reasonable, low preparation temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

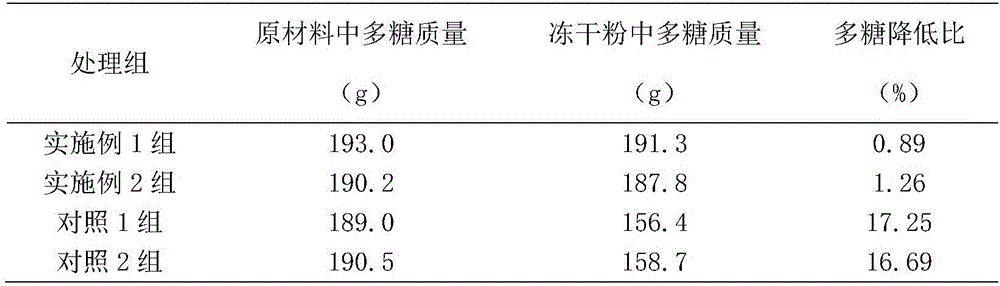

Examples

Embodiment 1

[0031] The preparation technology of dendrobium officinale freeze-dried powder comprises the following steps:

[0032] (1) Raw material preparation: get Dendrobium officinale meeting the requirements of the "Pharmacopoeia of the People's Republic of China" (2015 edition), wash with water, remove sundries, and rinse with purified water;

[0033] (2) Cut into pieces: mechanically cut into sections, cut into 2-4cm;

[0034] (3) Crushing and beating: add pure water according to the ratio of solid-liquid ratio 1g: 100ml for crushing and beating, grinding speed: 3000rpm, operating temperature: 40°C, pass through a 30-mesh filter, and receive the pulp;

[0035] (4) Vacuum drying: Take the above juice, pre-freeze overnight at -18°C to -20°C, then vacuum freeze-dry, set the cold trap temperature to -26°C, vacuum degree -0.9 to -0.1 Pa, freeze-drying time 18h, The final sublimation time is 14 hours, and the sublimation temperature is 40-45°C;

[0036] (5) Pulverization: the freeze-dri...

Embodiment 2

[0038] The preparation process of the freeze-dried powder of Dendrobium officinale is the same as in Example 1, except that in step (4), the freeze-drying time is 20 hours, and the sublimation is 16 hours.

Embodiment 3

[0040] The preparation technology of dendrobium officinale freeze-dried powder comprises the following steps:

[0041] (1) Raw material preparation: get Dendrobium officinale meeting the requirements of the "Pharmacopoeia of the People's Republic of China" (2015 edition), wash with water, remove sundries, and rinse with purified water;

[0042] (2) Cut into pieces: mechanically cut into sections, cut into 2-4cm;

[0043] (3) Crushing and beating: add pure water according to the ratio of solid-liquid ratio 1g: 80ml for crushing and beating, grinding speed: 3500rpm, operating temperature: 42°C, pass through a 28-mesh filter, and receive the pulp;

[0044] (4) Vacuum drying: Take the above juice, pre-freeze overnight at -18°C ~ -20°C, then vacuum freeze-dry, set the cold trap temperature at -24°C, vacuum degree -1.1 Pa, freeze-drying time 16h, and finally sublimate for 12h , the sublimation temperature is 38°C;

[0045] (5) Pulverization: the freeze-dried powder obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com