camshaft with cover

A technology of camshafts and closing covers, which is applied to cams, components with teeth, engine components, etc., and can solve problems such as failure to supply oil, blockage of supply holes, and changes in oil pressure status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

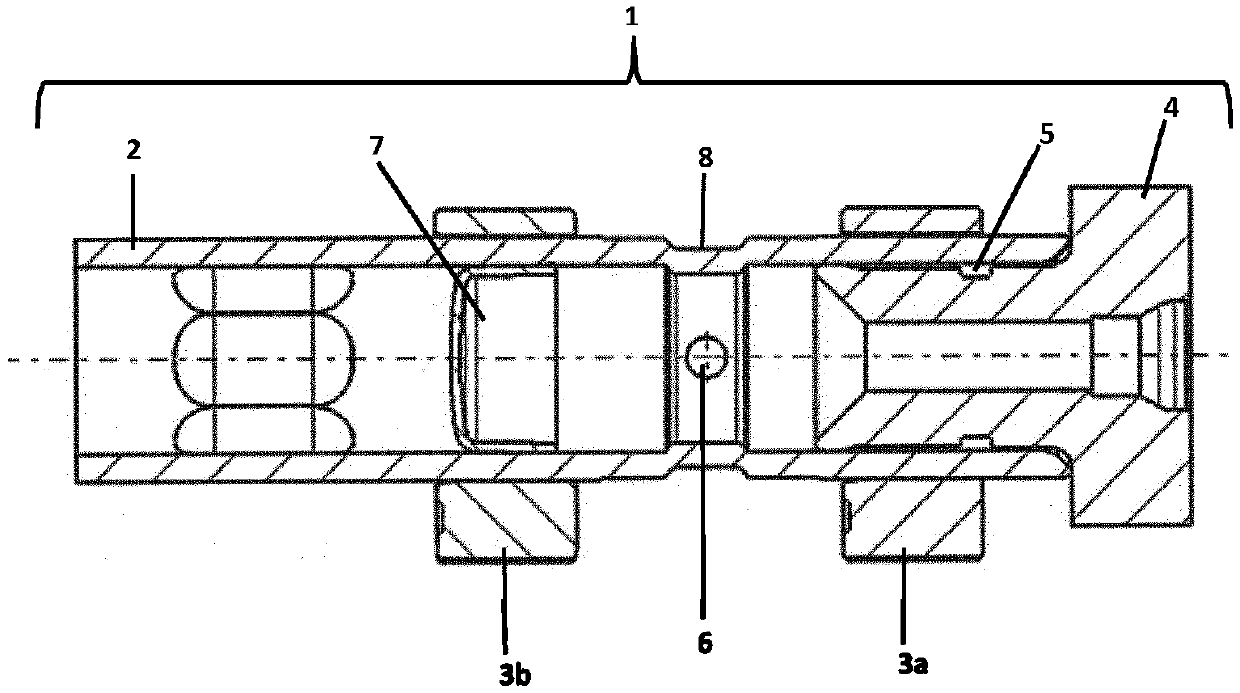

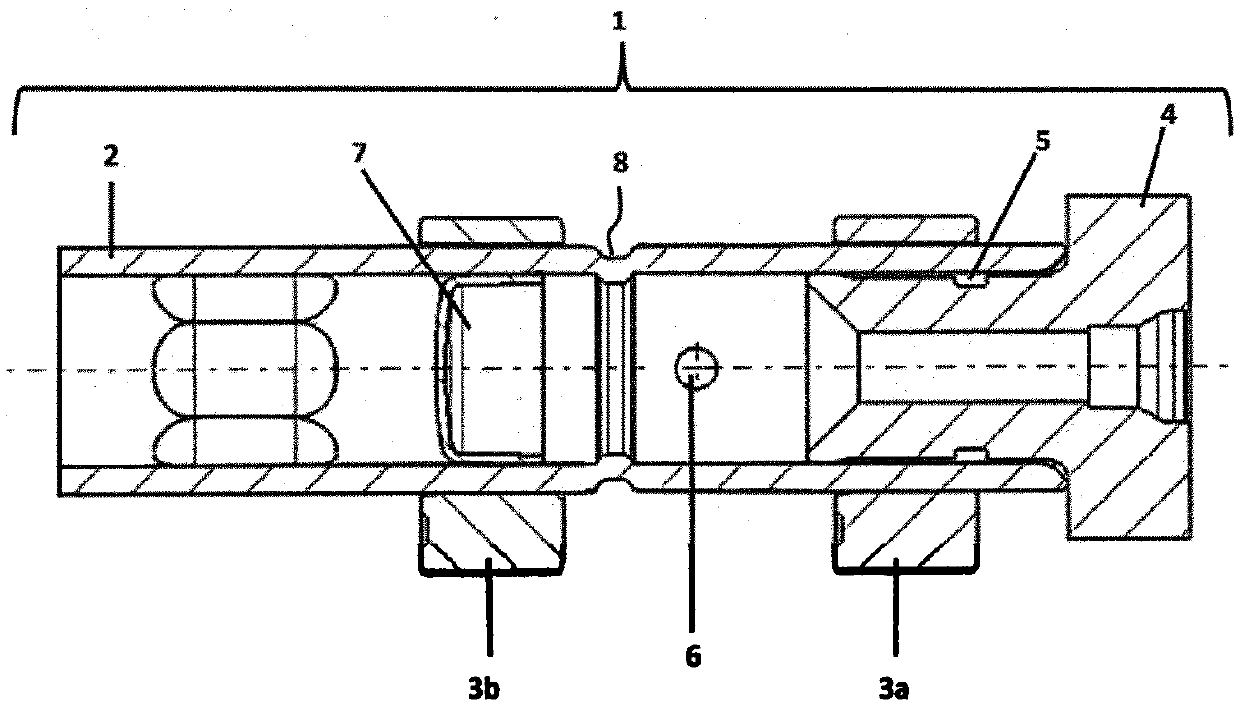

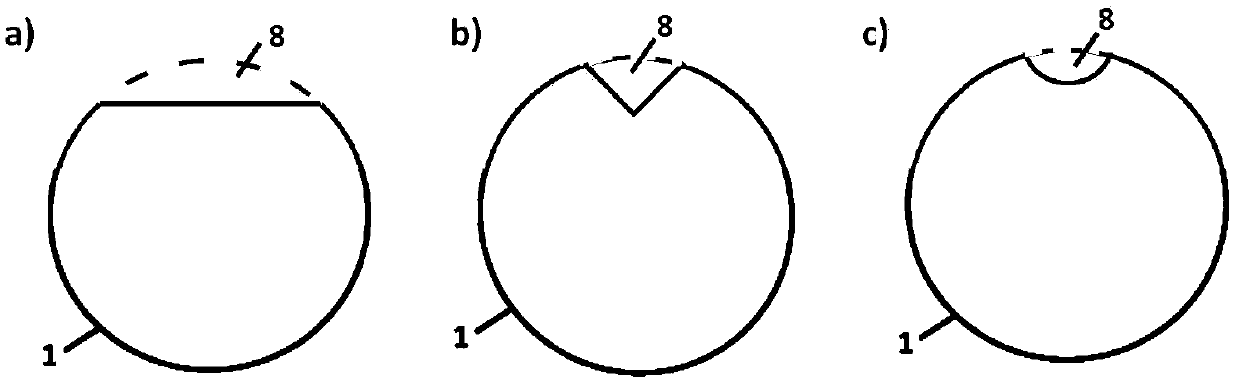

[0034] figure 1 A camshaft 1 is shown comprising a hollow shaft 2 fitted with cams 3a and 3b and closed by an end piece 4 provided with an annular seal 5 . The camshaft 1 is provided with supply openings 6 via which oil is supplied to adjacent bearings and devices. In order to prevent oil from penetrating into undesired areas, a closure cover 7 is positioned in the camshaft. In the example shown, the closure cover 7 has been pressed under the cam 3 b and is thus clamped in the hollow shaft 2 . The closure cover 7 is axially spaced from the cam 3a. In order that the closure cap 7 does not slide during operation and thus does not block the supply opening 6 , a recess 8 in the form of an inwardly rolled part is located in the hollow shaft 2 which prevents the closure cap 7 from sliding. In this example, the recess 8 in the form of an inwardly rolled portion is rotationally symmetrical and is located at the same axial position as the feed hole 6 . The cross-sectional area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com