Laser cutting device for machining accessories of ship crane

A technology for marine cranes and laser cutting, which can be used in auxiliary devices, laser welding equipment, metal processing equipment, etc., and can solve problems such as small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

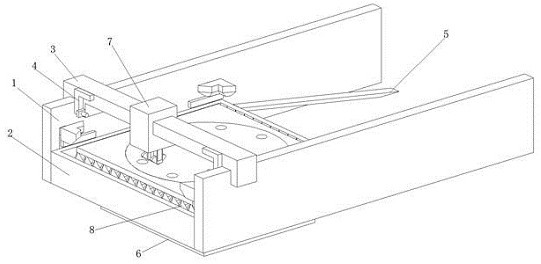

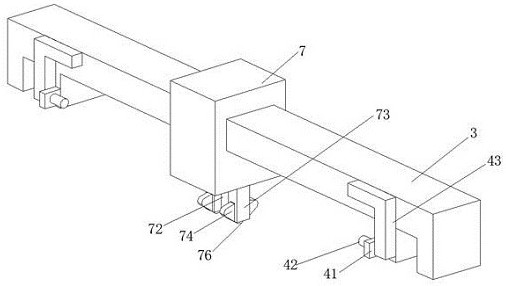

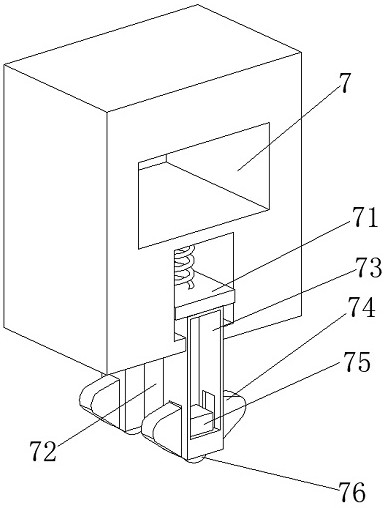

[0027] A laser cutting device for processing accessories of marine cranes, such as Figure 1-Figure 7 As shown, it includes a support plate 1, the surface of the support plate 1 is fixedly connected with a workbench 2, the top of the workbench 2 is slidably connected with a linear motor 3, the surface of the linear motor 3 is slidably connected with a moving block 7, and the inner wall of the moving block 7 slides A slide plate 71 is connected, and the bottom of the slide plate 71 is fixedly connected with a laser head 72 and two support rods 73 respectively. The inner walls on both sides of the support rod 73 are connected with a rotating block 74 through torsion spring rotation, and the bottom wall inside the support rod 73 is fixedly connected There is a switch 75, the bottom of the support rod 73 is movably connected with a ball 76, the inner wall of the workbench 2 is fixedly connected with a support plate 8, and the right side of the workbench 2 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com