Method for supplementing lithium to lithium ion battery pole piece

A lithium-ion battery and pole piece technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as unfavorable production efficiency, high energy, and potential safety hazards for operators, and achieve the first coulombic efficiency and cycle performance improvement, Low environmental and equipment requirements, and the effect of reducing capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

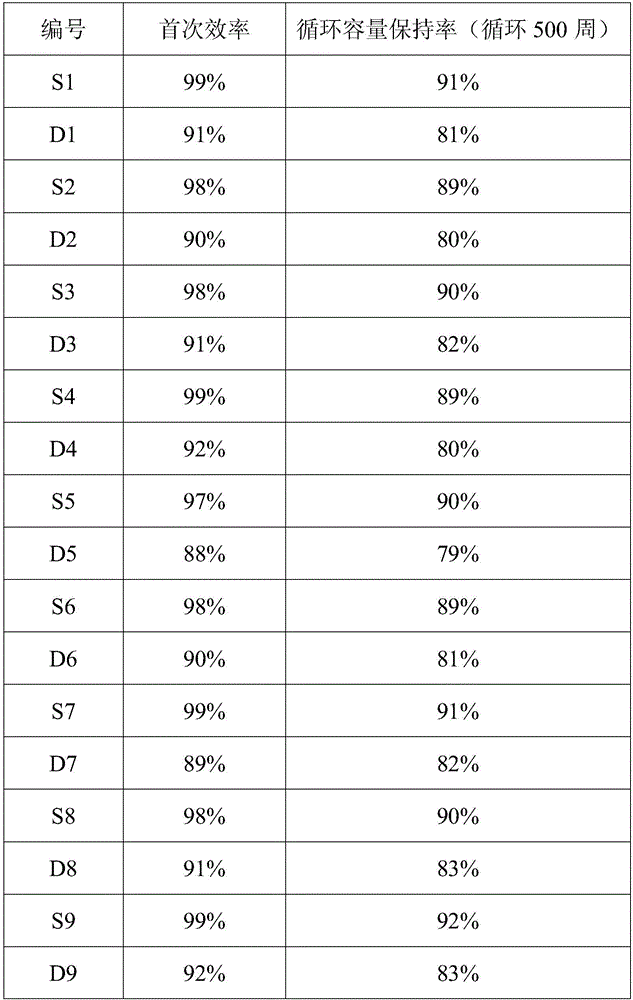

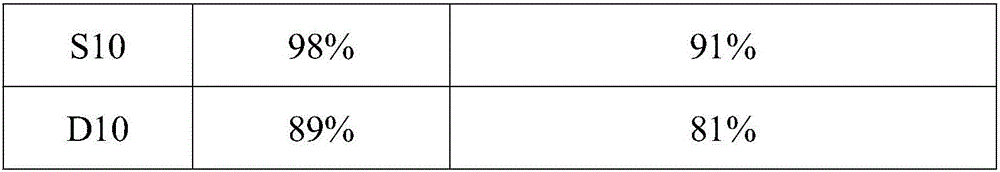

Examples

Embodiment 1

[0037] This embodiment provides a method for replenishing lithium to the positive electrode sheet of a lithium-ion battery, which includes the following steps:

[0038]Step (1), preparing lithium colloidal particles with a core-shell structure, wherein the shell material is polyaniline, and the core layer material is metal lithium, with a mass ratio of 1:50; in a nitrogen atmosphere, add polyaniline to the reaction vessel and N-methylpyrrolidone, the mass ratio is 1:3, the temperature is controlled below 60°C, and the polyaniline is fully dissolved with sufficient stirring; then the dried metal lithium powder is added, and the particle size is 100nm, and fully stirred Fully disperse the metal lithium powder until a uniform dispersion solution is formed, bake at a temperature of 100°C for 8 hours to remove the solvent, and obtain polyaniline-coated lithium colloidal particles of metal lithium;

[0039] Step (2), lithium colloidal particles prepared in step (1), positive active ...

Embodiment 2

[0041] This embodiment provides a method for replenishing lithium to the positive electrode sheet of a lithium-ion battery, which includes the following steps:

[0042] Step (1), preparing lithium colloidal particles with a core-shell structure, wherein the shell material is styrene-butadiene rubber, and the core layer material is metal lithium, with a mass ratio of 1:99; in an argon atmosphere, add Styrene-butadiene rubber and N-methylpyrrolidone, the mass ratio is 1:5, the temperature is controlled below 60°C, and the styrene-butadiene rubber is fully dissolved by stirring thoroughly; then the dried metal lithium powder is added, and the particle size is 0.1nm, fully stirred to disperse the metal lithium powder until a uniform dispersion solution is formed, baked at 120°C for 12 hours to remove the solvent, and obtained lithium colloidal particles of styrene-butadiene rubber-coated lithium metal;

[0043] Step (2), lithium colloidal particles prepared in step (1), positive a...

Embodiment 3

[0045] This embodiment provides a method for replenishing lithium to the positive electrode sheet of a lithium-ion battery, which includes the following steps:

[0046] Step (1), preparing lithium colloidal particles with a core-shell structure, wherein the shell material is polypyrrole, the core layer material is metal lithium, and its mass ratio is 1:80; in a nitrogen atmosphere, add polypyrrole to the reaction vessel and tetrahydrofuran, the mass ratio is 1:5, the temperature is controlled below 60 ° C, and the polypyrrole is fully dissolved by stirring; then the dried metal lithium powder is added, and the particle size is 0.1nm, and the metal lithium is fully stirred. The powder is fully dispersed until a uniform dispersion solution is formed, and the solvent is removed by baking at 120°C for 12 hours to obtain lithium colloidal particles of polypyrrole-coated lithium metal;

[0047] Step (2), dispersing the lithium colloidal particles prepared in step (1) in N-methylpyrr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com