A constant temperature metal bath

A technology of constant temperature metal and temperature sensor, applied in the field of analytical instruments, can solve the problems of large temperature overshoot, low temperature control accuracy, low temperature stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] A kind of thermostatic metal bath of the present invention, its specific embodiment is:

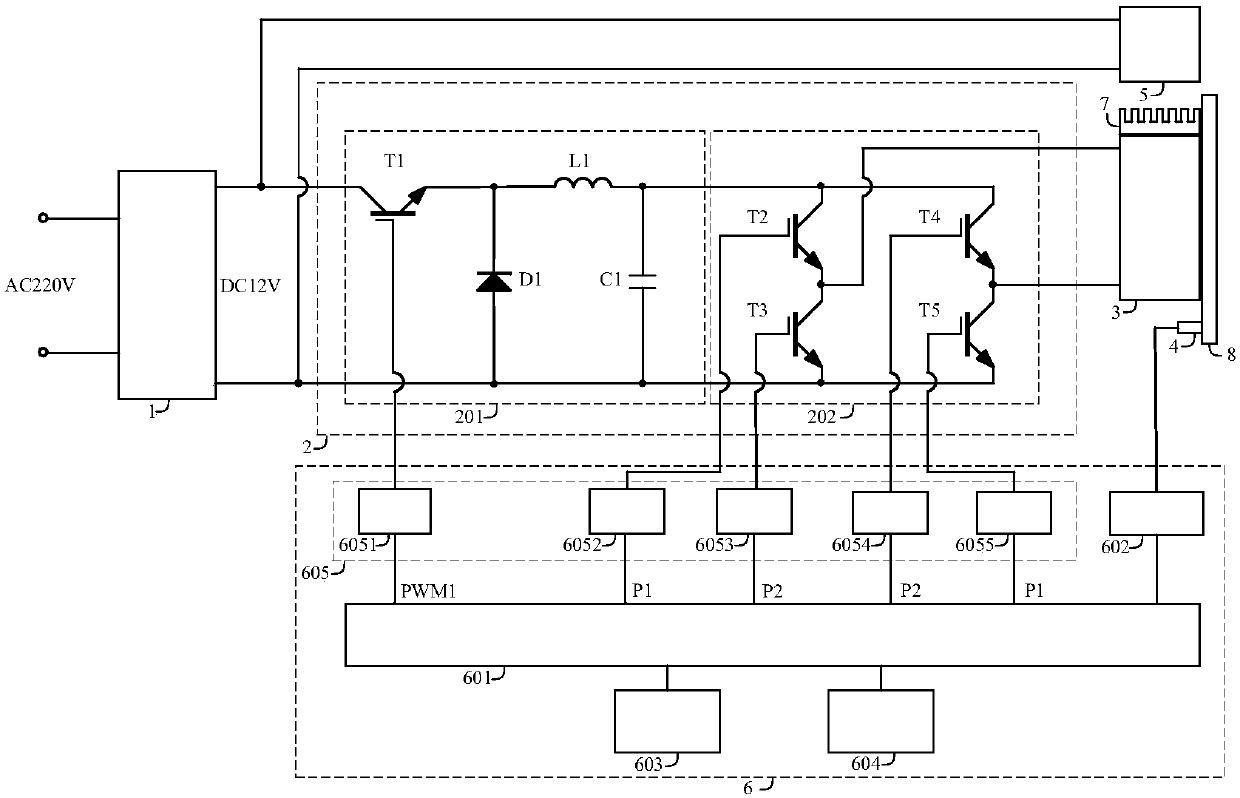

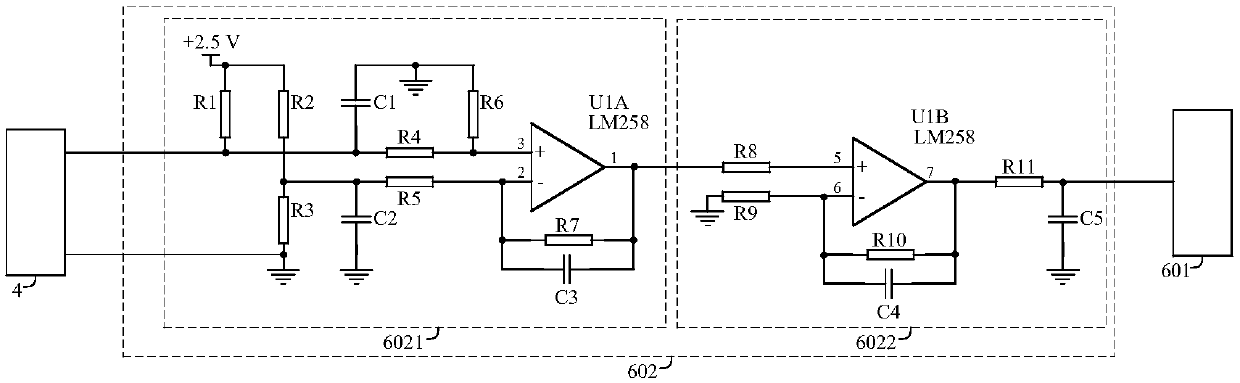

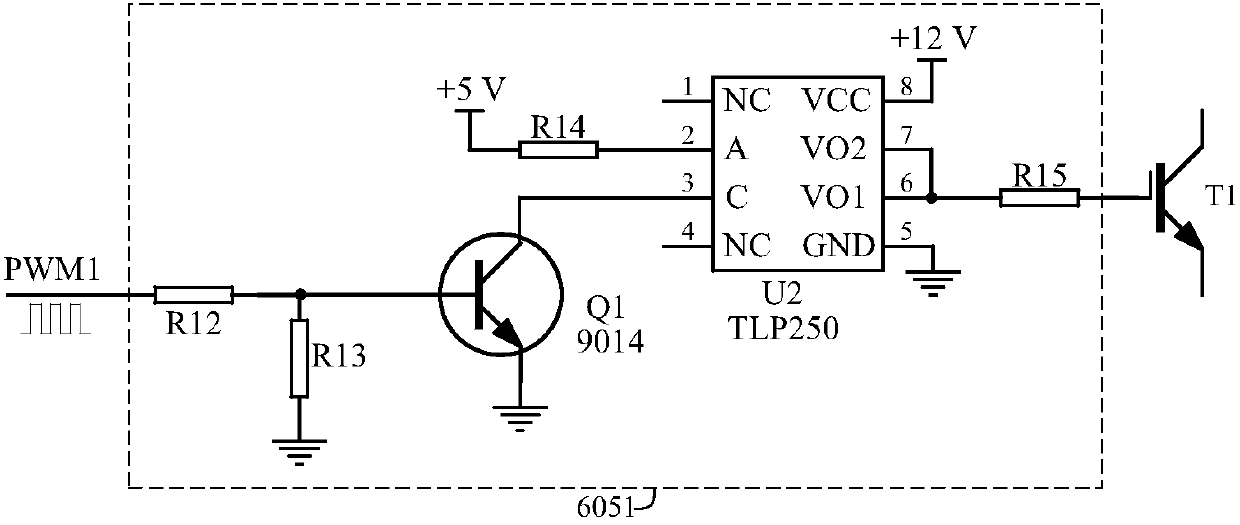

[0033] A kind of constant temperature metal bath of the present invention, see figure 1 As shown, it includes: DC12V power adapter 1, main circuit 2, semiconductor cooling sheet 3, temperature sensor 4, fan 5, control circuit 6, heat sink 7, and heat conduction platform 8. The semiconductor cooling chip 3 forms a circuit with the AC220V AC power supply through the main circuit 2 and the DC12V power adapter 1, and the two surfaces of the semiconductor cooling chip 3 are in close contact with the heat conducting platform 8 and the heat sink 7 with good thermal conductivity through the thermal conductive silicone grease. ; The power switch tubes T1, T2, T3, T4, T5 of the main circuit 2 are connected to the control circuit 6 through wires; the temperature sensor 4 is tightly attached to the heat conduction platform 8 through heat-conducting silicone grease and connected to the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com