Electrothermal coupling processing system for characterizing phase transformtaion behavior of material

A processing system and thermal coupling technology, applied in the investigation stage/state change, etc., can solve problems such as difficult to apply materials and quantify the dynamic behavior of material phase transitions, and achieve the effect of expanding the scale range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

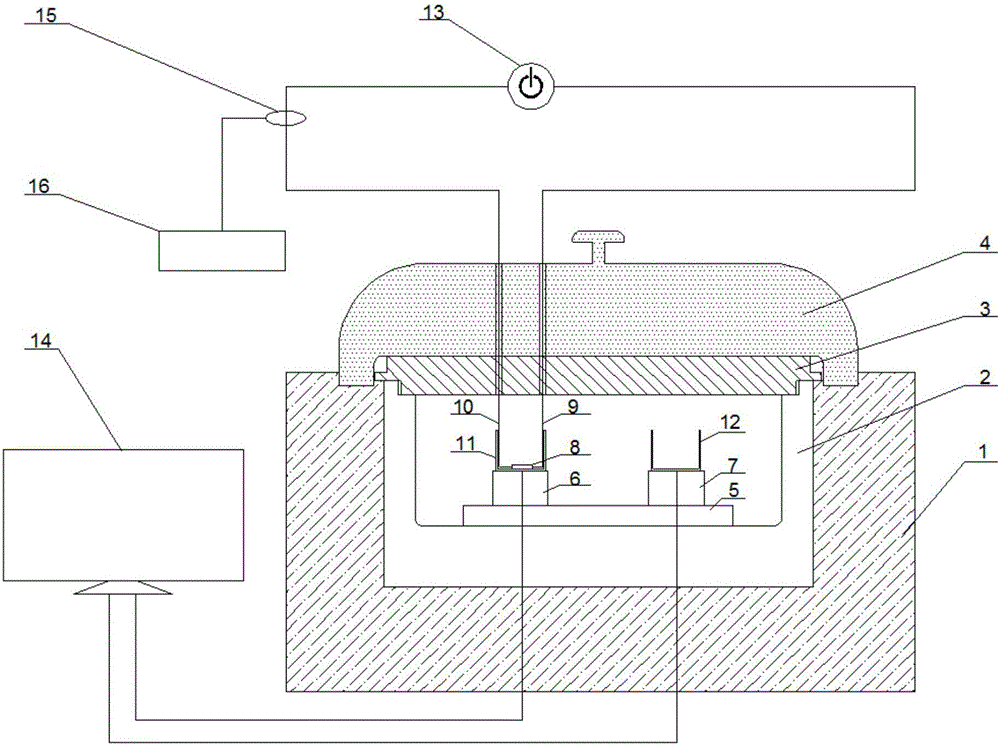

[0021] In order to better understand the electric-thermal coupling processing system for characterization of material phase transition behavior of the present invention, the present invention will be further described below with reference to the accompanying drawings, but the implementation method of the present invention is not limited thereto.

[0022] Such as figure 1 As shown, an electric-thermal coupling processing system for characterization of material phase transition behavior includes a power supply system, an execution system, a data acquisition and control system, and a monitoring system; the power supply system includes a power supply 13 and connecting wires; the execution system mainly includes a differential The scanning calorimeter; the data acquisition and control system mainly includes a processor 14; the monitoring system mainly consists of a Hall sensor 15 and an alarm 16. The power supply 13 can output both direct current and alternating current.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com