Zero-position locking test device and test method for servo mechanism

A technology of a servo mechanism and a test device, applied in the field of servo systems, can solve the problems of long-term testing of the zero-position locking function of multiple servo products, and achieve the effects of high test efficiency, good versatility, and convenient assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

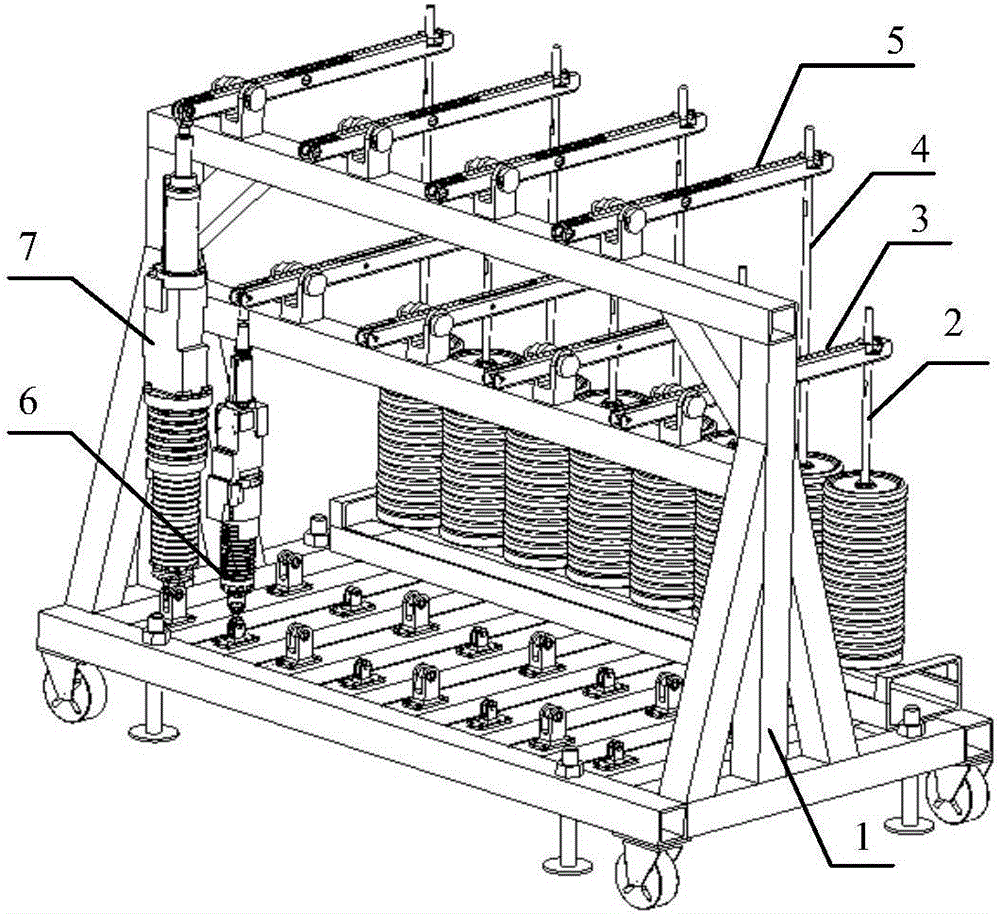

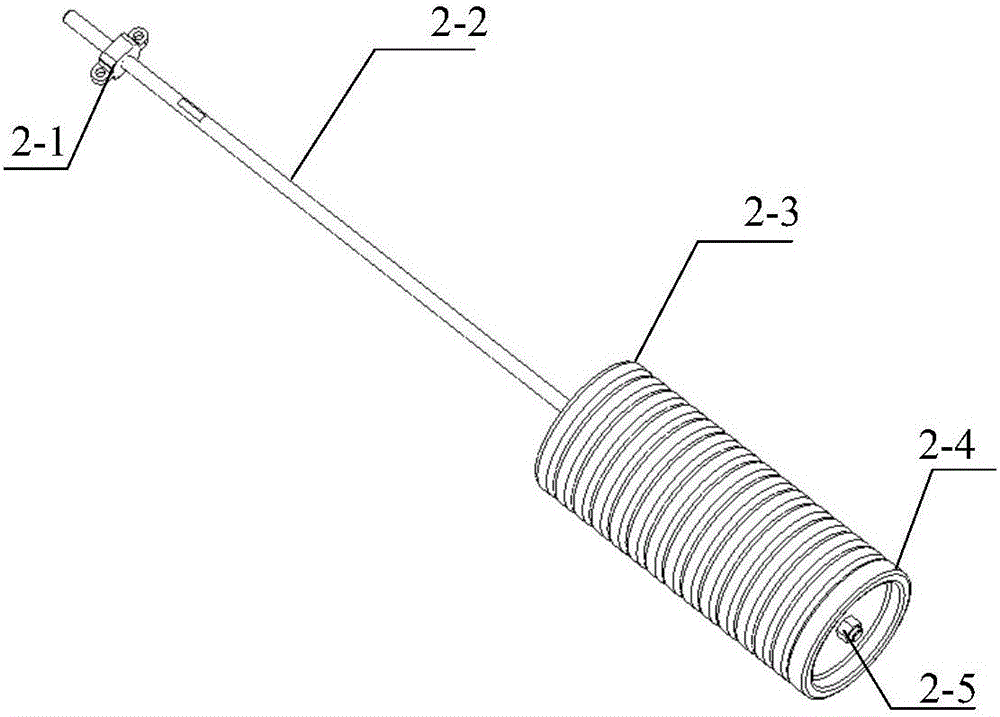

[0044] The structural layout of a servo mechanism zero lock test device is as follows: figure 1 As shown, it consists of a frame assembly 1, 4 mass block assemblies 4 and 4 mechanical levers 5. The device is loaded by a combination of a mass block assembly and a mechanical lever. The mass block assembly applies a loading force, the mechanical lever amplifies the loading force, and applies the amplified loading force to the servo mechanism. Each mechanical lever is equipped with two installation stations for tension and compression, which can realize the loading transformation of the product in the direction of tension and compression. The whole device has a total of 8 stations, which can test 4 servo mechanisms at the same time.

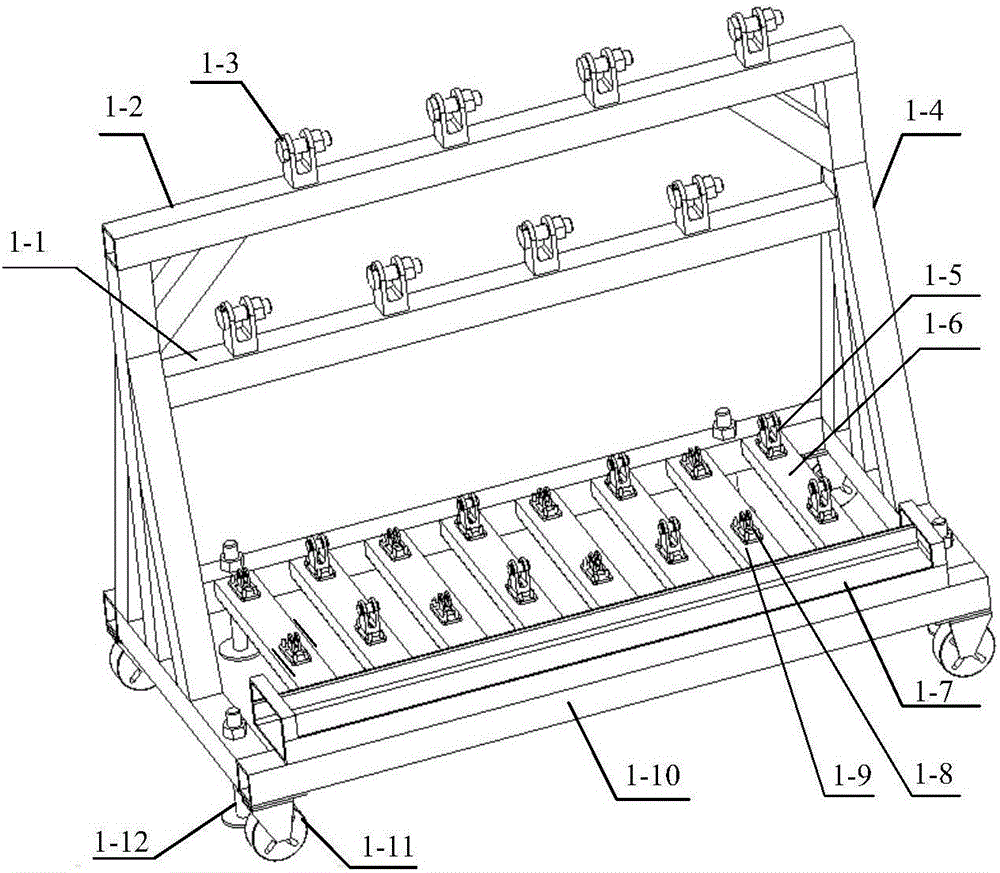

[0045] The frame assembly 1 is a frame structure welded with channel steel, square steel pipes, square steel plates, etc., and is the body of the test bench. The structural layout of the rack components is as follows figure 2 As shown, it mainly...

Embodiment 2

[0049] The structural layout of a servo mechanism zero lock test device is as follows: figure 1 As shown, it is composed of a frame assembly 1, 4 mass block assemblies 2, 4 mechanical levers 3, 4 mass block assemblies 4, and 4 mechanical levers 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com