Production method of forced centering observation mark stake for precision engineering measurement

A technology of forced centering and precision engineering, applied in the direction of measuring devices, instruments, etc., can solve problems such as large measurement errors and poor manufacturing stability, and achieve the effects of reducing settlement and offset, improving stability, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

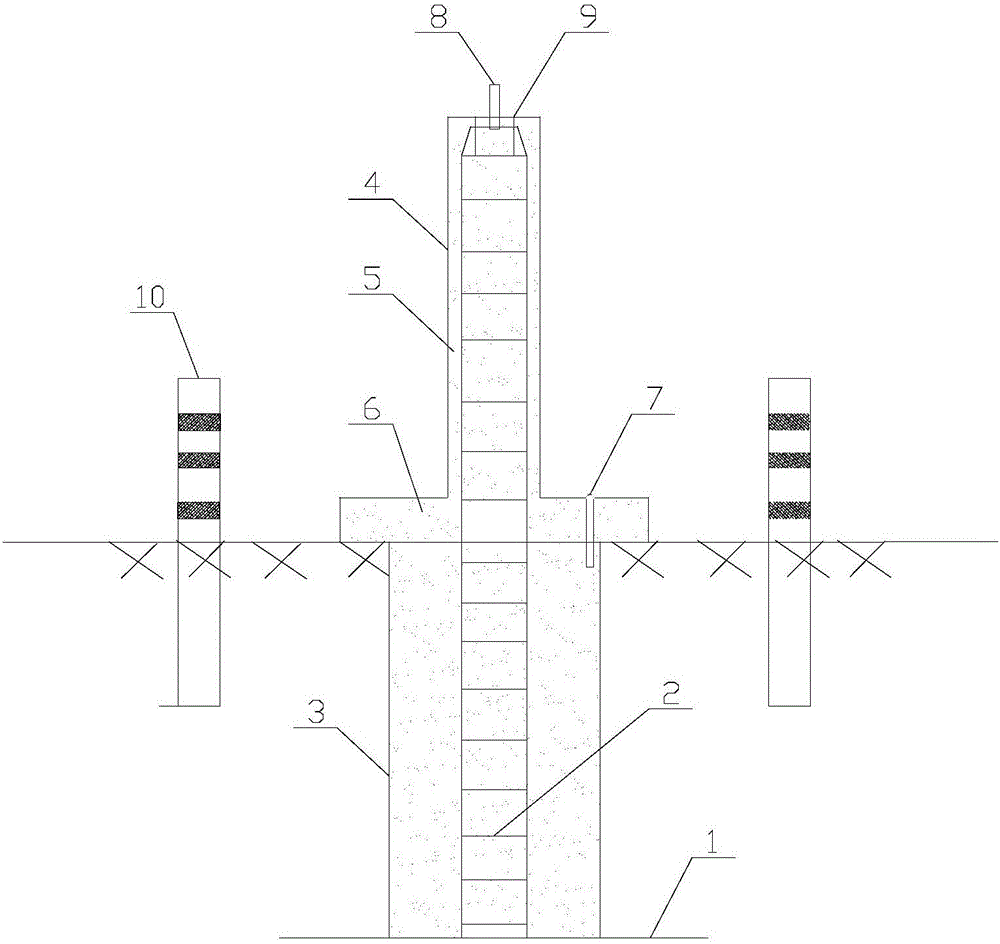

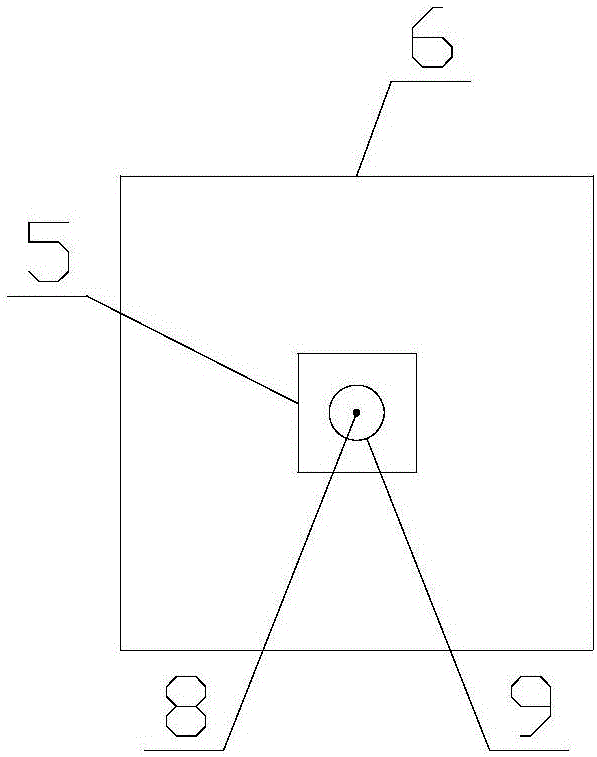

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0026] Such as figure 1 and figure 2 As shown, this embodiment discloses a method for making a mandatory centering observation stake for precision engineering measurement, which is carried out according to the following steps:

[0027] (1) Manually excavate the pile hole at the designed hole position until the pile hole is excavated to bedrock 1; during the pile hole excavation, attention should be paid to controlling the verticality of the pile hole, checking the quality of the hole, and cleaning the pile hole. Empty soil, remove water accumulated in the pile hole.

[0028] (2) After the excavation of the pile holes is completed, the reinforcement cage 2 shall be hoisted into the pile holes. Within the range of 1000-1500mm, it is subject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com