Boiler burning system

A boiler combustion and boiler technology, applied in the direction of combustion methods, control combustion, combustion equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

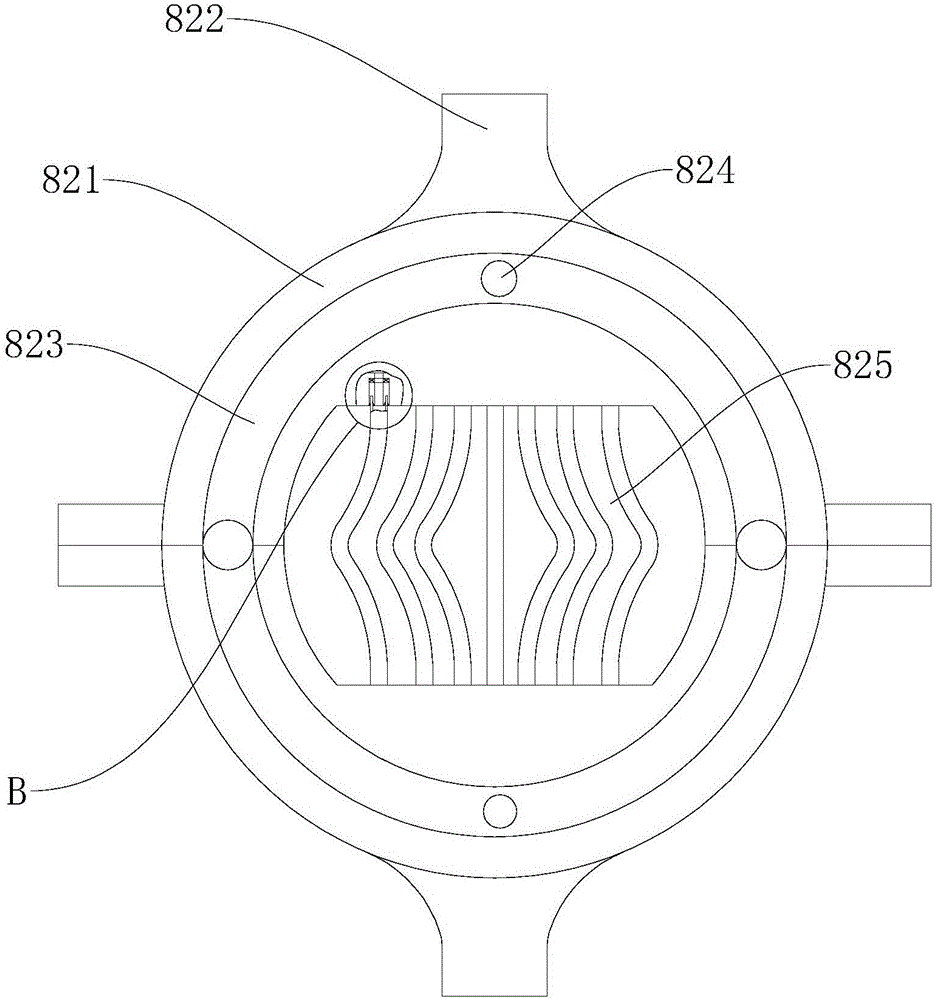

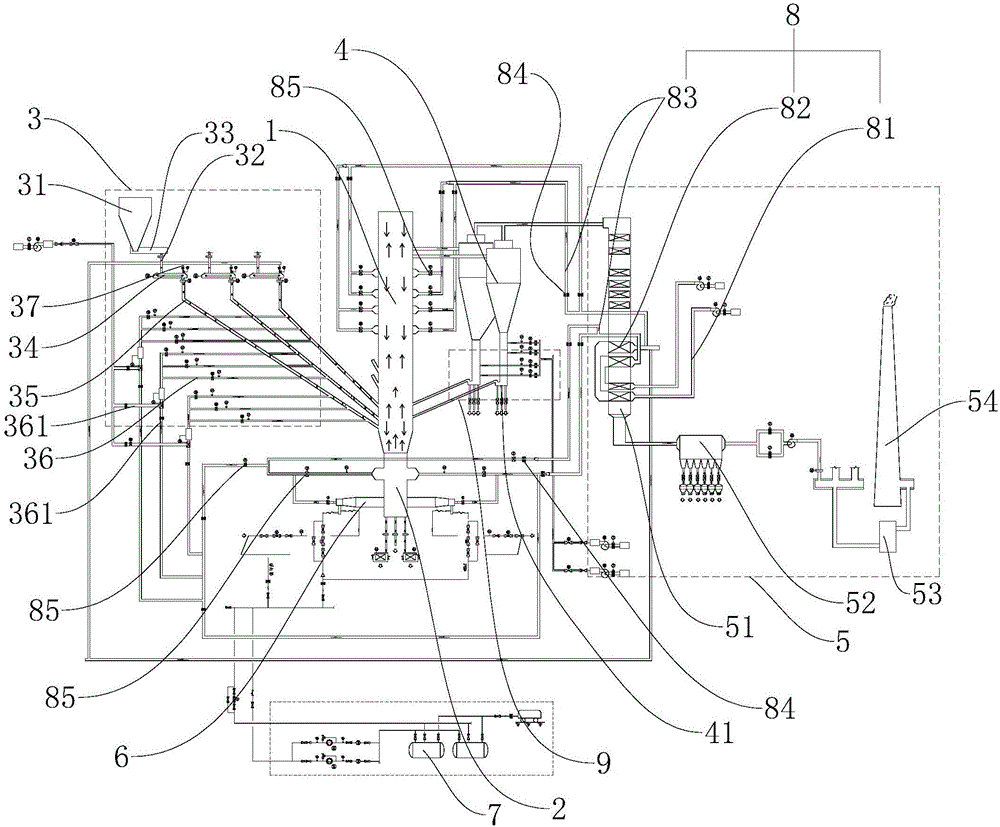

[0049] A boiler combustion system, such asfigure 1 As shown, including boiler 1, the bottom of boiler 1 is provided with air chamber 2, and the part of boiler 1 near air chamber 2 is provided with feeding system 3, boiler 1 is connected with cyclone separator 4, and tail gas treatment is provided at the end of cyclone separator 4 System 5, air chamber 2 is connected to an ignition system, and exhaust gas treatment system 5 is connected to a thermal circulation system, which is connected to boiler 1, cyclone separator 4, ignition system and feeding system 3 respectively. The boiler 1 is fed through the feeding system 3, and then ignited by the igniter 6 at the position of the air chamber 2, and the ignited fuel is blown up through the air chamber 2, let it rise, and flow in the boiler 1, so that the coal is burned by The original static state becomes d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com