Patch SMX carrier tape ironing machine

A technology of carrier tape ironing machine and patch, applied in the directions of external support, transportation packaging, packaging, etc., can solve the problems of high failure and maintenance rate, damage and tension of cover tape, long-term burnout, etc., to avoid peer devices and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

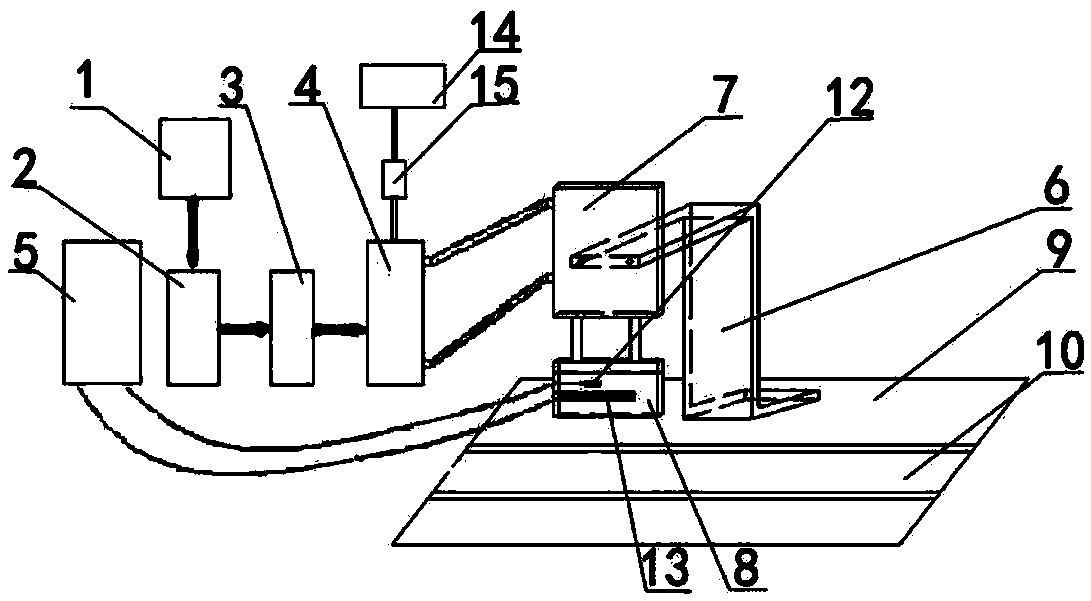

[0017] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0018] Refer to attached figure 1 , patch SMX carrier tape ironing machine, which includes a control mechanism and an actuator, the control mechanism is connected to the actuator through wires and air pipes, the control mechanism includes a foot switch 1, a relay 2, a time relay 3, a solenoid valve 4 and a temperature controller 5; the executive mechanism includes a "Z" type frame 6, a biaxial cylinder 7, a mold heating block 8 and a limit groove seat 9; the foot switch 1 is connected to the relay 2 through a wire, and the relay 2 passes through The wire is connected to the time relay 3, and the time relay 3 is connected to the solenoid valve 4 through the wire, and the solenoid valve 4 is connected to the double-axis cylinder 7 through the air pipe. The shaft cylinder 7 is installed on the upper end of the "Z" frame 6, and the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com