Hydraulic system of tear bomb powder hydraulic machine

A technology of powder hydraulic press and hydraulic system, which is applied in the field of hydraulic system to achieve the effect of ensuring density and ensuring uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

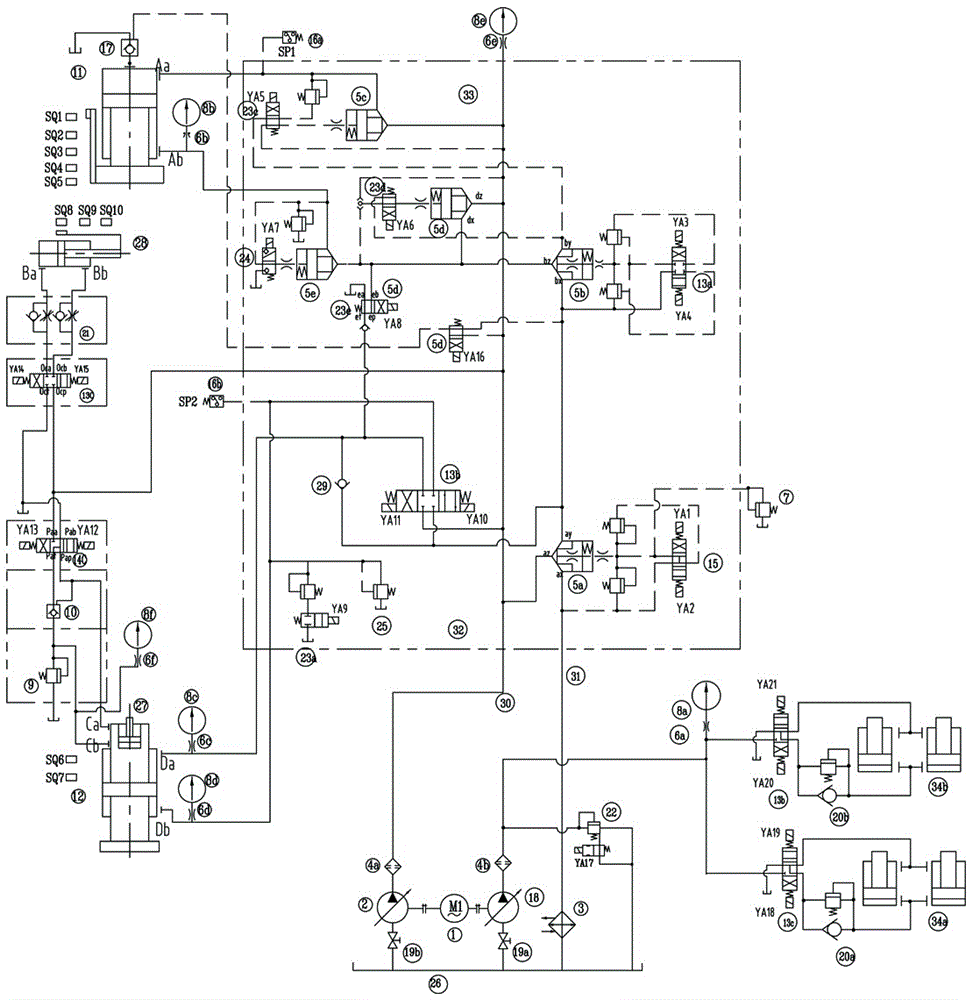

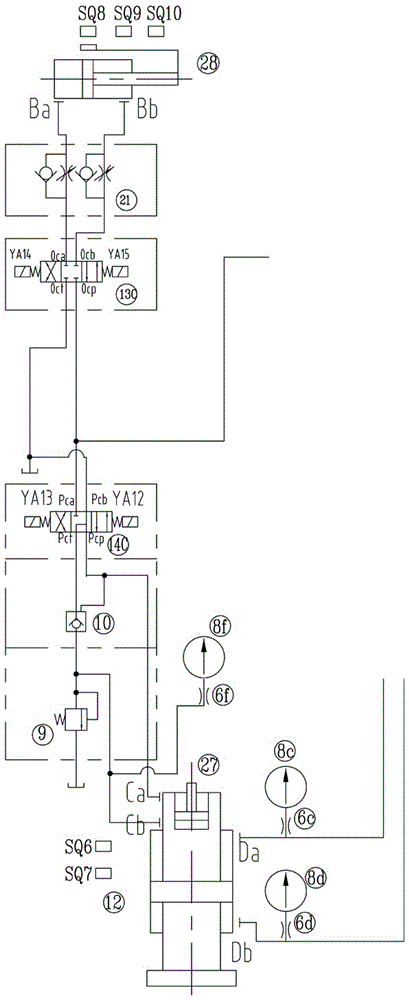

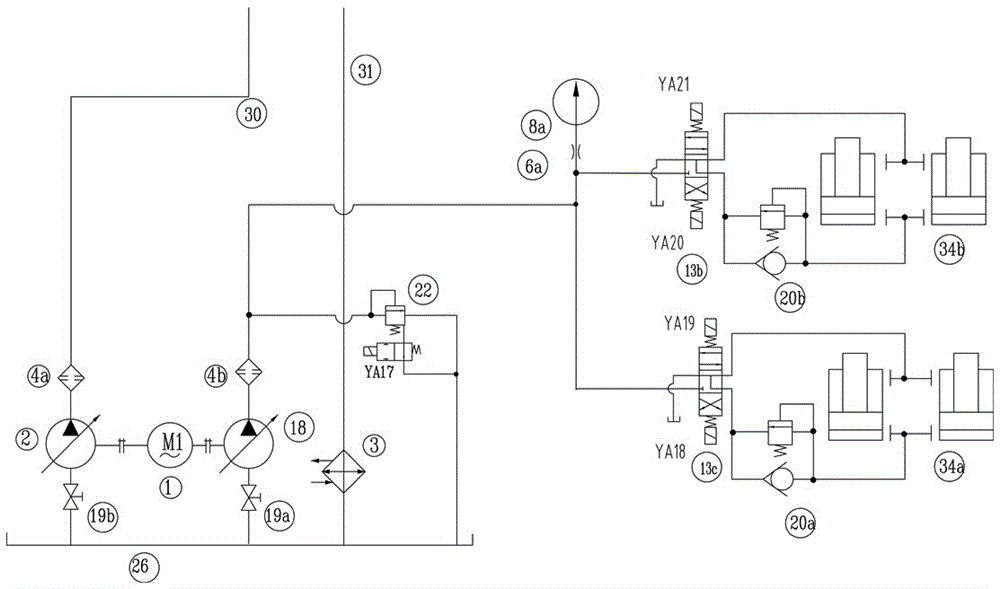

[0026] Such as Figure 1 to Figure 4 Shown is a tear gas powder hydraulic press hydraulic system, the tear gas powder hydraulic press hydraulic system includes: a control system, a cartridge valve system, an auxiliary system and an execution system; the control system is connected to the cartridge valve system and the auxiliary system, and the execution system is connected to the cartridge valve system. connected to the valve system.

[0027] The control system includes a motor 1, an axial piston pump 2, a vane pump 18, an oil filter 4, a cooler 3, a stop valve 19, an electromagnetic overflow valve 22 and an oil tank 26; 2 is connected with the vane pump 18, and drives the axial piston pump 2 and the vane pump 18 to absorb hydraulic oil from the oil tank 26. The axial pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com