Wet-laying spunlace jacquard non-woven fabric and preparation method for same

A wet-laid, non-woven technology, used in non-woven fabrics, textiles and papermaking, etc., to improve product strength, ensure entanglement, visual and hand jacquard effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The wet-laid spunlace jacquard non-woven fabric of the present invention is prepared from the following raw materials in weight percentage: 15% of viscose fiber, 10% of water-soluble fiber, and the balance of wood pulp.

[0033] In this embodiment, the viscose fiber is a zigzag flat viscose fiber with a length of 11 mm. The water-soluble fibers are water-soluble polyvinyl alcohol fibers with a length of 7mm. The length of the wood pulp was 2 mm.

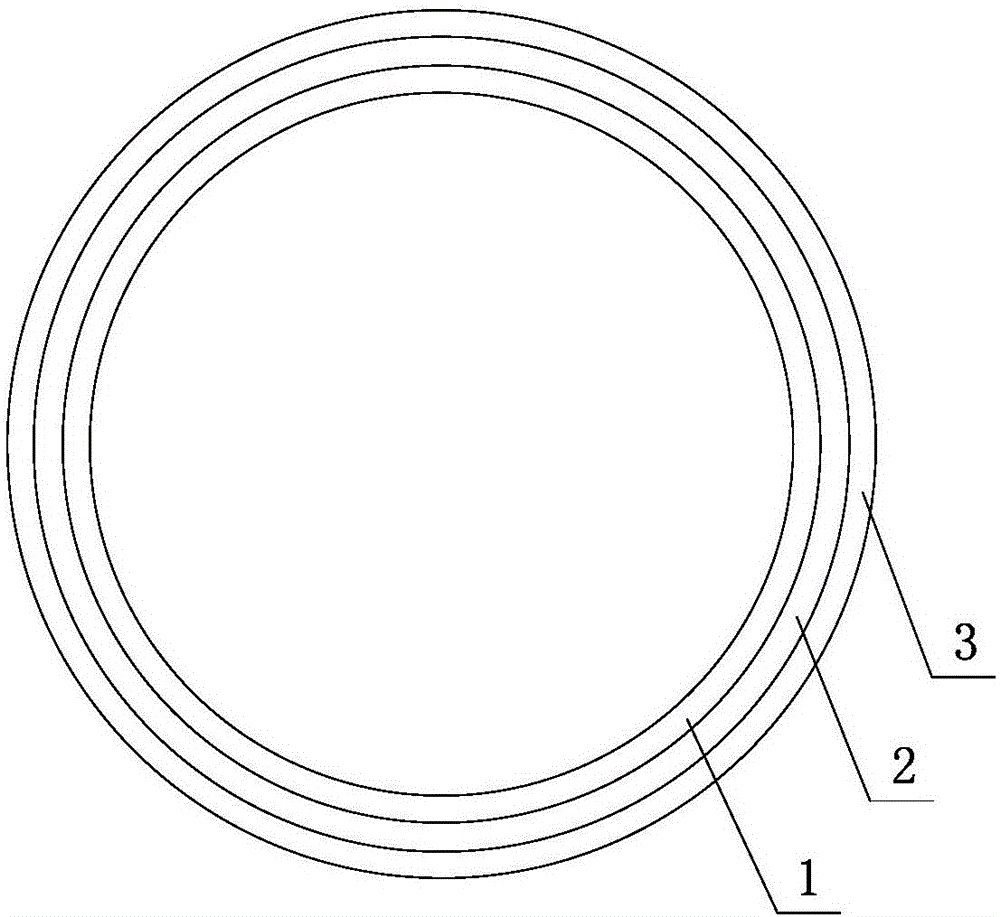

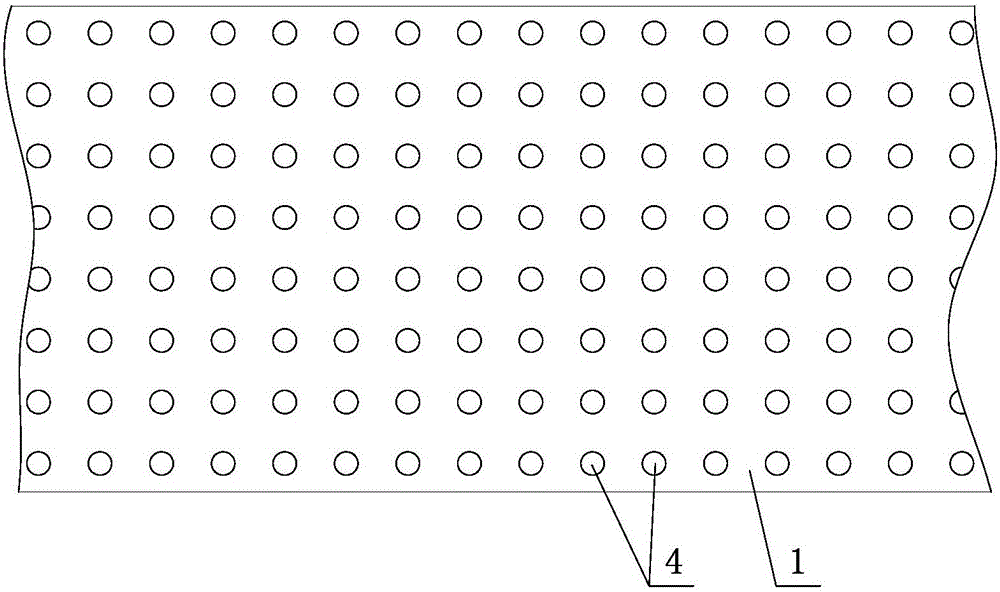

[0034] combine figure 1 , figure 2 , image 3 , Figure 4 Shown, the preparation method of wet-laid spunlace jacquard non-woven fabric of the present invention comprises the following steps:

[0035] (1) Separately dissolve and adjust the concentration of each raw material according to the feeding ratio;

[0036] (2) Transport the thickened raw materials to the mixing pipe for uniform mixing to form a slurry;

[0037] (3) sizing;

[0038] (4) Forming and spunlace; wherein, the spunlace process adopts a special drum c...

Embodiment 2

[0046] The wet-laid spunlace jacquard non-woven fabric of the present invention is prepared from the following raw materials in weight percentage: 30% of viscose fiber, 5% of water-soluble fiber, and the balance of wood pulp.

[0047] In this embodiment, the viscose fiber is a zigzag flat viscose fiber with a length of 13 mm. The water-soluble fibers are water-soluble polyvinyl alcohol fibers with a length of 5mm. The length of the wood pulp was 4 mm.

[0048] combine figure 1 , figure 2 , image 3 , Figure 4 Shown, the preparation method of wet-laid spunlace jacquard non-woven fabric of the present invention comprises the following steps:

[0049] (1) Separately dissolve and adjust the concentration of each raw material according to the feeding ratio;

[0050] (2) Transport the thickened raw materials to the mixing pipe for uniform mixing to form a slurry;

[0051] (3) sizing;

[0052] (4) Forming and spunlace; wherein, the spunlace process adopts a special drum co...

Embodiment 3

[0060] The wet-laid spunlace jacquard non-woven fabric of the present invention is prepared from the following raw materials in weight percentage: 22% of viscose fiber, 8% of water-soluble fiber, and the balance of wood pulp.

[0061] In this embodiment, the viscose fiber is a zigzag flat viscose fiber with a length of 12 mm. The water-soluble fiber is a water-soluble polyvinyl alcohol fiber with a length of 6mm. The length of the wood pulp was 3 mm.

[0062] combine figure 1 , figure 2 , image 3 , Figure 4 Shown, the preparation method of wet-laid spunlace jacquard non-woven fabric of the present invention comprises the following steps:

[0063] (1) Separately dissolve and adjust the concentration of each raw material according to the feeding ratio;

[0064] (2) Transport the thickened raw materials to the mixing pipe for uniform mixing to form a slurry;

[0065] (3) sizing;

[0066] (4) Forming and spunlace; wherein, the spunlace process adopts a special drum cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com