Coreless moulding composite material pole tower and manufacturing method thereof

A composite material and composite fiber technology, applied in the field of hollow tower poles for power transmission lines, can solve the problems of low tensile strength, complex preparation process, and high mold cost, and achieve high product strength, excellent corrosion resistance, and manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

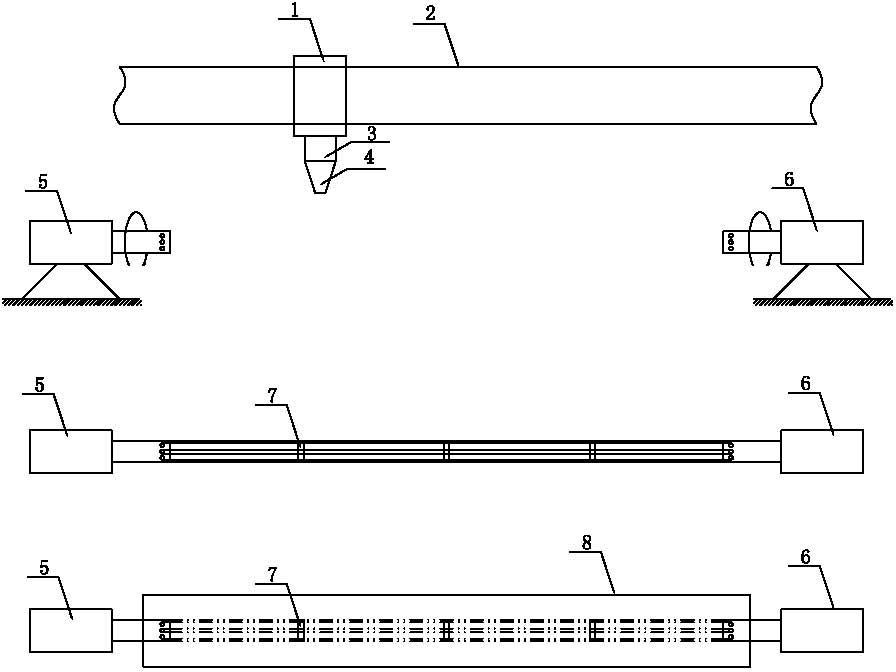

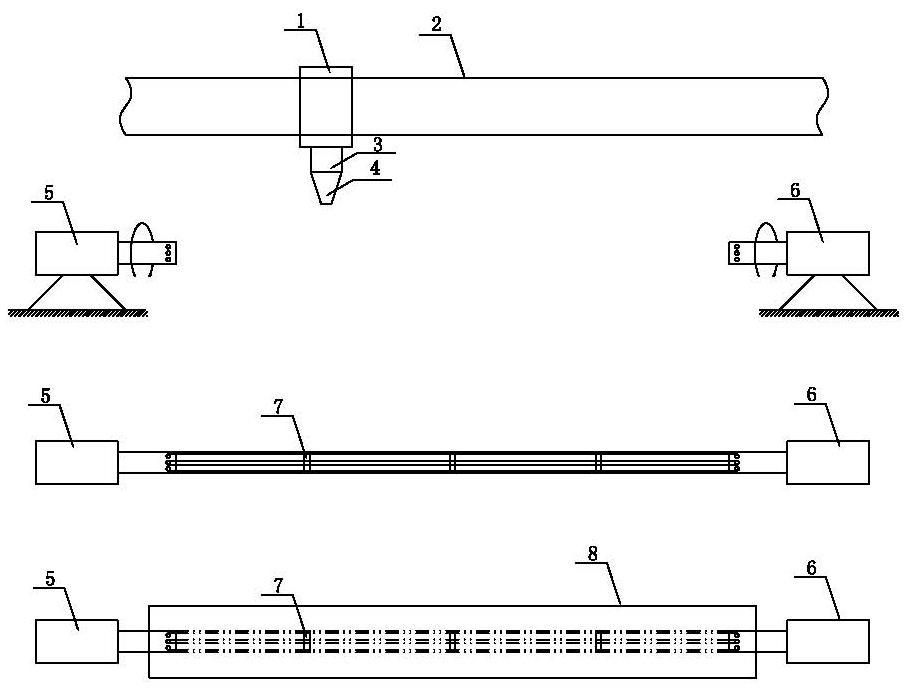

[0037] like figure 1 , 2 shown.

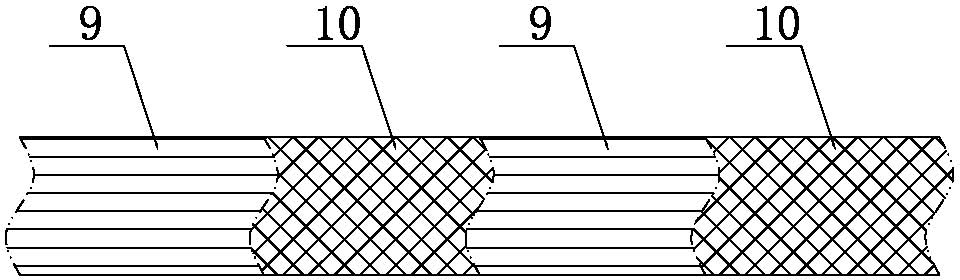

[0038] A coreless molded composite pole tower, the cross-sectional shape of which is circular tube or polygonal (such as square tube, rhombus or hexagonal), and the cross-sectional area is large at one end and small at the other end with a smooth transition. It consists of at least A layer of longitudinal composite material (such as carbon fiber, glass fiber, basalt fiber, etc., the same below) fiber layer 9 along the axial direction and at least one layer of oblique composite material fiber wound on each layer of longitudinal composite material fiber layer 9 The winding layer 10 is composed of the longitudinal fiber layer 9 and the oblique fiber winding layer 10 connected by thermosetting adhesive, such as figure 1 shown.

[0039] figure 1 The preparation method of the shown coreless molded composite pole tower is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com