A kind of production method of water-repellent and oil-proof needle-punched felt filter material

A water- and oil-repellent, production method technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of inability to apply moisture resistance, oil resistance and acid resistance, affecting the filtration effect of filter felt, and short cleaning cycle, etc. Achieve the effect of improving the saturated impregnation effect, ensuring the continuity of production, and improving the peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

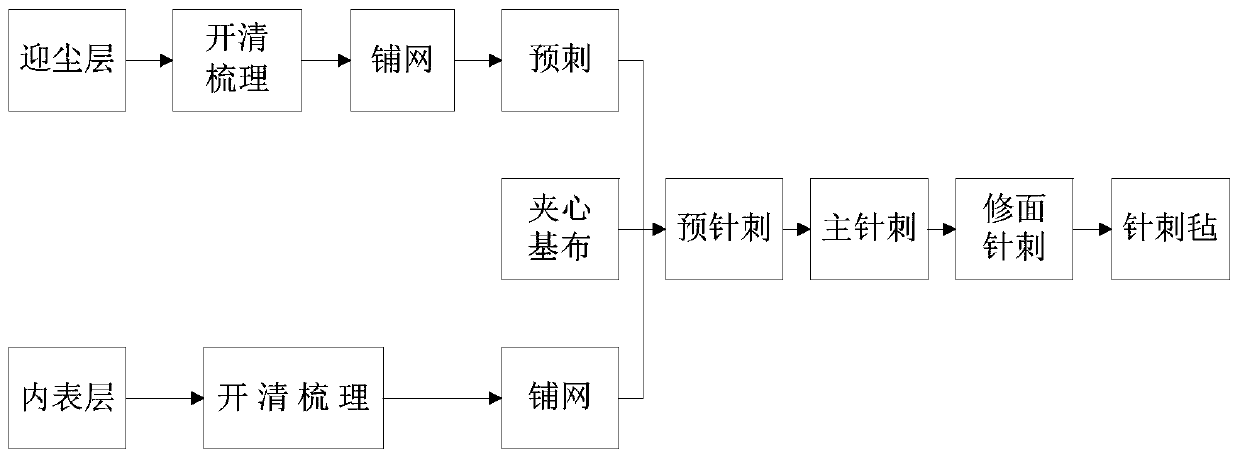

[0038] A method for producing a water-repellent and oil-repellent needle-punched felt filter material, comprising the steps of:

[0039] Step 1: Pretreatment of the dust layer and inner surface, including:

[0040] Step 1.1: Cleaning and combing the dust layer, laying the net, and pre-stabbing; where:

[0041] Opening and carding: use horn nails, carding needles and card clothing to open the fibers of the dust layer to achieve the effect of uniform mixing and carding transfer;

[0042] Laying: Under the clamping of the upper and lower carbon curtains of the laminating machine, the fiber webs of the dust-facing layer output by carding are moved synchronously to perform cross-lapping to achieve the ideal layering effect;

[0043] Pre-punching: Through the reciprocating movement of the needle plate and the needles, the fiber web fibers of the dust-facing layer output from the laying are forced into the interior of the fiber web, and the fluffy fiber web is compressed and thinned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com