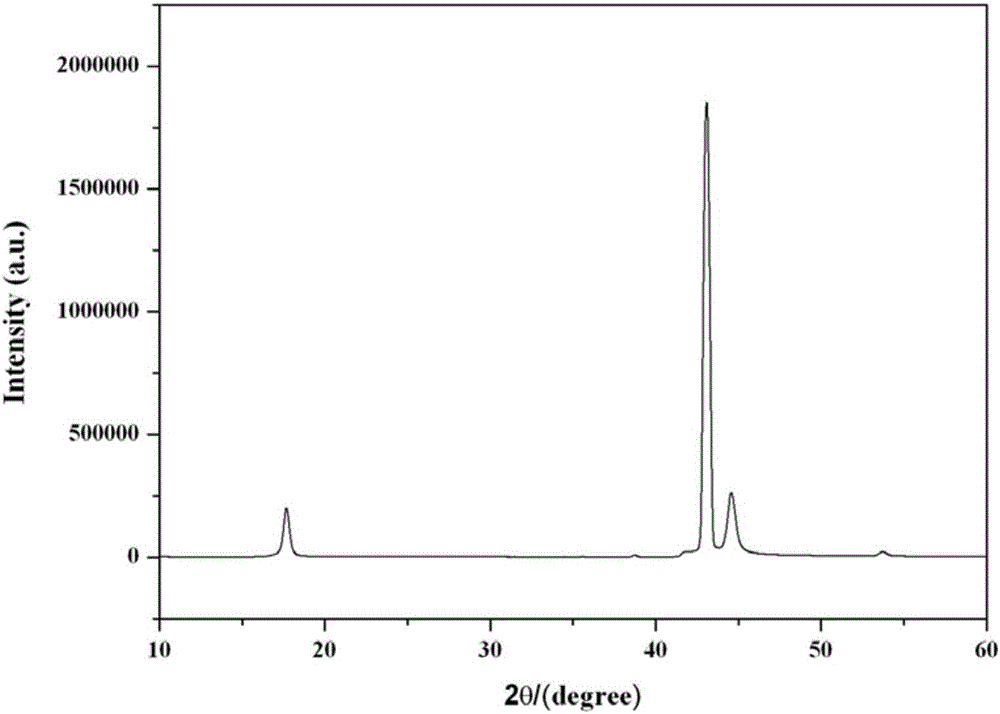

Method for preparing preferred-orientation bismuth telluride thermoelectric thin film

A thermoelectric thin film and preferred orientation technology, which is applied in the manufacture/processing of thermoelectric devices, junction lead-out materials of thermoelectric devices, ion implantation and plating, etc. High lattice matching and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

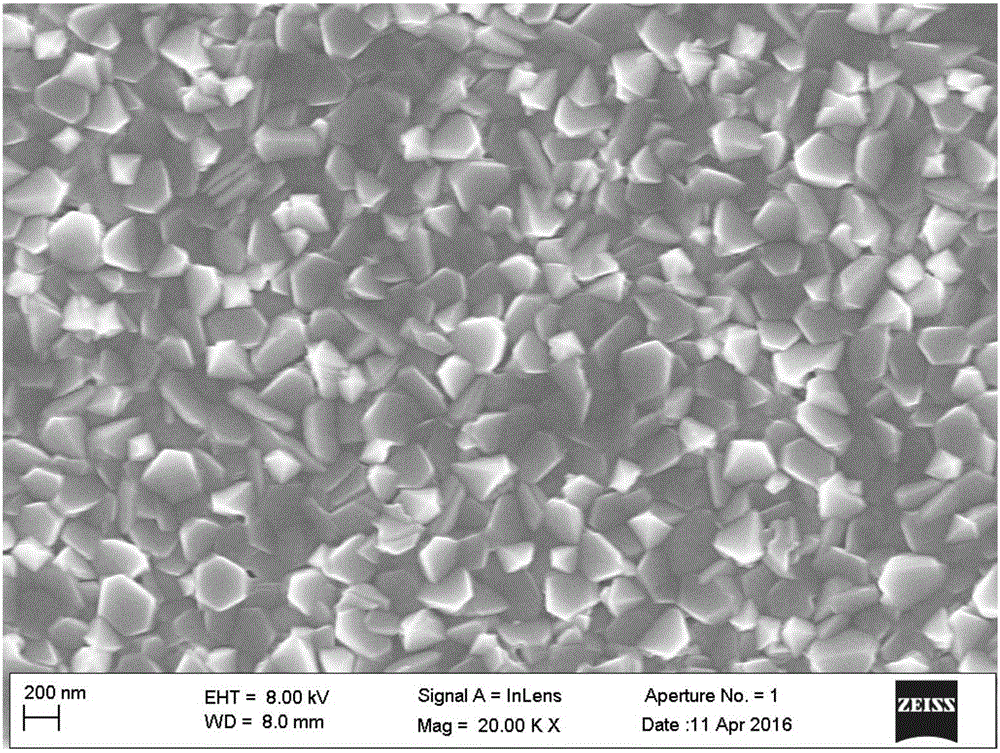

Embodiment 1

[0027] (1) Mix metal powder Bi and Te with a purity of 99.999% according to the molar ratio of Bi:Te=2:3, and use a hot isostatic pressing device under the condition of 200MPa to make a high-density bismuth telluride alloy target, And install the bismuth telluride alloy target in the vacuum chamber of the magnetron sputtering equipment;

[0028] (2) Soak the (00l)-oriented magnesium oxide (MgO) single crystal in a mixed solution containing concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 1:3 for 20 minutes, and then place it in a beaker containing acetone and a beaker of alcohol in turn. and the beaker of ultrapure aqueous solution, ultrasonically cleaned for 10 min respectively, and finally with high-purity nitrogen (N 2 ) drying the magnesium oxide (MgO) single crystal;

[0029] (3) installing the magnesium oxide single crystal cleaned in step (2) on the substrate, and baking at a temperature of 50° C. for 20 minutes;

[0030] (4) Adjust the distance...

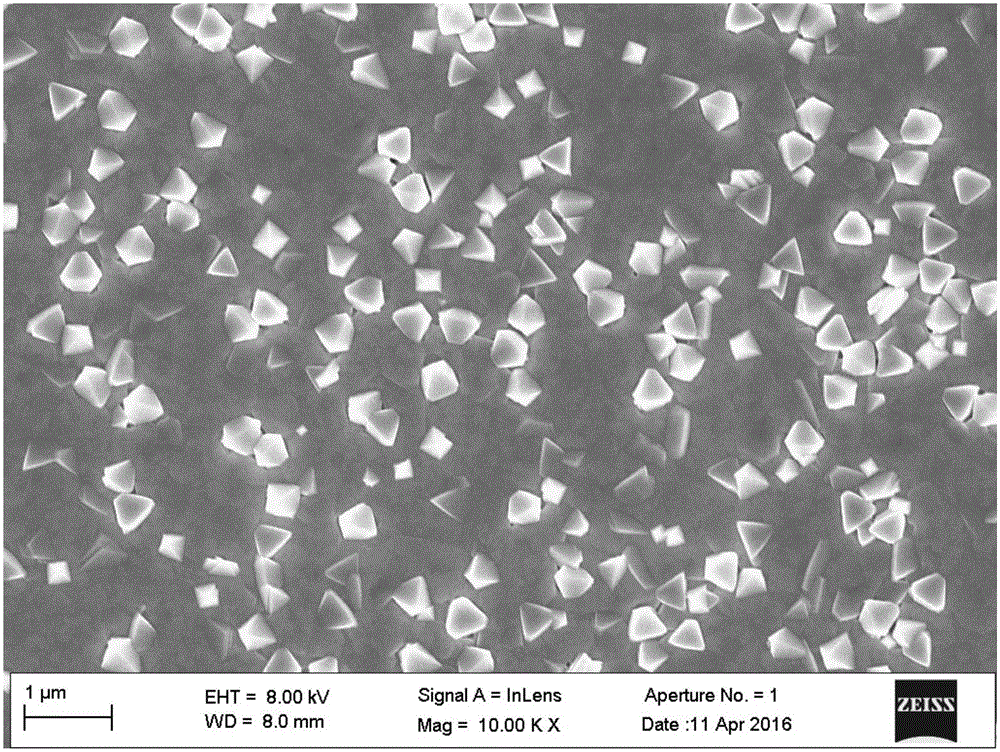

Embodiment 2

[0037] (1) Mix metal powder Bi and Te with a purity of 99.999% according to the molar ratio of Bi:Te=2:3, and use a hot isostatic pressing device under the condition of 200MPa to make a high-density bismuth telluride alloy target, And install the bismuth telluride alloy target in the vacuum chamber of the magnetron sputtering equipment;

[0038] (2) Soak the (00l)-oriented magnesium oxide (MgO) single crystal in a mixed solution containing concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 1:3 for 25 minutes, and then place it in a beaker containing acetone and alcohol in turn. and the beaker of ultrapure aqueous solution, ultrasonically cleaned for 10 min respectively, and finally with high-purity nitrogen (N 2 ) drying the magnesium oxide (MgO) single crystal;

[0039] (3) installing the magnesium oxide single crystal cleaned in step (2) on the substrate, and baking at a temperature of 60° C. for 30 minutes;

[0040] (4) Adjust the distance between the...

Embodiment 3

[0047] (1) Mix metal powder Bi and Te with a purity of 99.999% according to the molar ratio of Bi:Te=2:3, and use a hot isostatic pressing device under the condition of 200MPa to make a high-density bismuth telluride alloy target, And install the bismuth telluride alloy target in the vacuum chamber of the magnetron sputtering equipment;

[0048] (2) Soak the (00l)-oriented magnesium oxide (MgO) single crystal in a mixed solution containing concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 1:3 for 30 minutes, and then place it in a beaker containing acetone and alcohol in turn. and the beaker of ultrapure aqueous solution, ultrasonically cleaned for 10 min respectively, and finally with high-purity nitrogen (N 2 ) drying the magnesium oxide (MgO) single crystal;

[0049] (3) installing the magnesium oxide single crystal cleaned in step (2) on the substrate, and baking at a temperature of 70° C. for 40 minutes;

[0050] (4) Adjust the distance between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com