Aircraft damage metal micro-droplet jetting 3D printing in-situ rapid repairing method

A 3D printing and micro-droplet spraying technology, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of poor practicability and achieve the effect of strong practicability, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

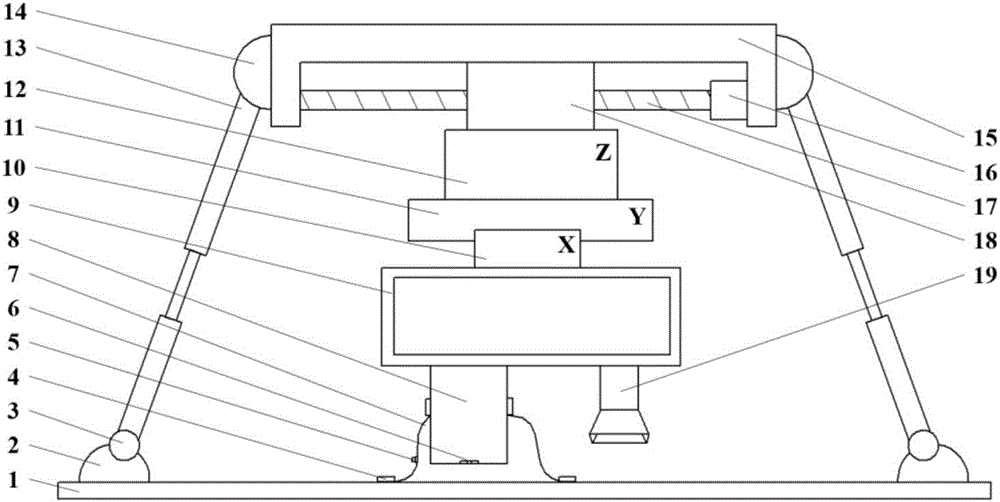

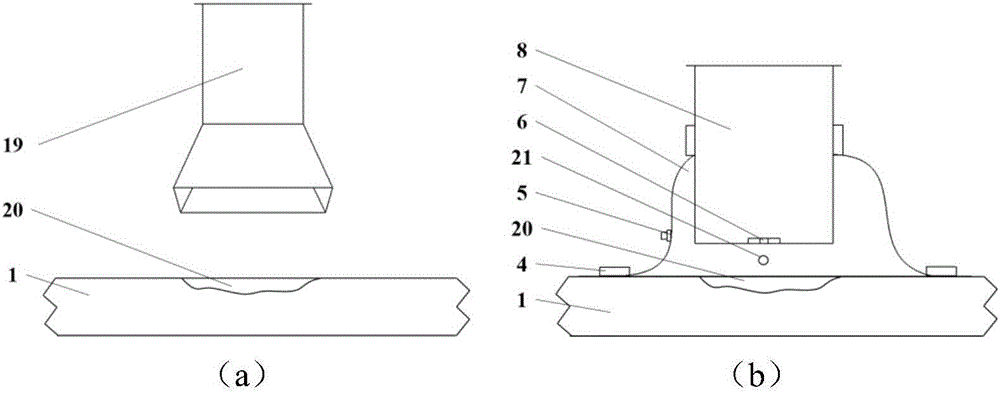

[0025] Example 1: Repair of corrosion pits on the surface of 7075 aluminum alloy structural parts of large transport aircraft.

[0026] In the application of this embodiment, first use the sandblasting process (or acid-base corrosion method) to pre-treat the corrosion pits in the area 20 to be repaired on the damaged part 1 of the large-scale transport aircraft, remove the oxide layer and impurities on the surface, and then remove the oxide layer and impurities on the surface. The suction cup 2 adsorbs and fixes the in-situ rapid repair device of metal droplet injection 3D printing on the surface of the damaged aircraft part 1, and quickly locks the universal joint 3 and the telescopic rod by adjusting the quick locking telescopic rod 13 and the corresponding vacuum suction cup Universal joint 14, so that the two-dimensional laser profile scanner 19 is located directly above the area to be repaired 20, and then the two-dimensional laser profile scanner 19 is used in conjunction...

Embodiment 2

[0027] Example 2: Repair of scratches and cracks on the surface of the 2024 aluminum alloy skin of a small unmanned aerial vehicle.

[0028]The process of this embodiment is basically the same as that of Embodiment 1. The difference is mainly because the application object is a small unmanned aerial vehicle, and its volume is small, so it is impossible to use the vacuum chuck 2 to spray the entire metal droplet into the 3D printing prototype. The quick repair device is adsorbed and fixed on the surface of the damaged part 1 of the small unmanned aerial vehicle. At this time, the vacuum suction cup 2 can be replaced with a support seat, and then the adjustment of the fast locking telescopic rod 13 makes the whole repair device overhead on a small unmanned aerial vehicle. Above the man-machine, secondly, the raw material used in this embodiment is 2024 aluminum alloy, so the heating temperature inside the droplet generator needs to be adjusted accordingly. For 2024 aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com