Method for producing fuel ethanol based on irradiation pre-treated straw

A technology of fuel ethanol and pretreatment, which is applied in the directions of biofuel and fermentation to achieve the effect of increasing the processing capacity, improving the processing efficiency and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

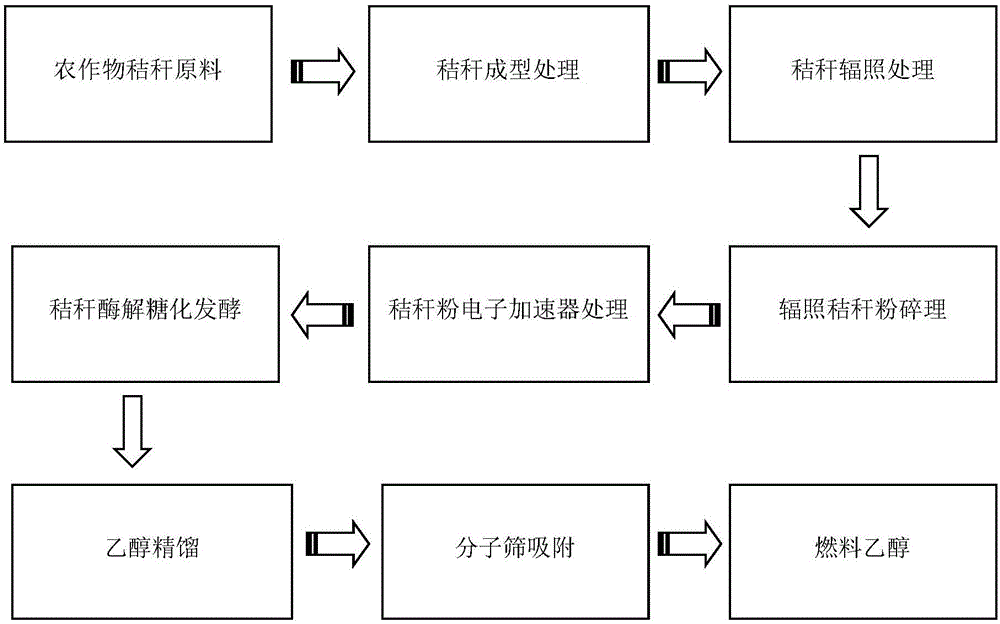

[0039] a kind of like figure 1The method for producing fuel ethanol based on irradiation pretreatment stalks of the present invention comprises the following steps:

[0040] 1. Raw material preparation: After collecting the naturally dried rice straws in the farmland, they are bundled into straw blocks with the same specifications by the straw forming system (for example, pressed by a hydraulic baler). The volume size of the straw blocks is 900mm×500mm ×550mm (length × width × height), density is 500kg / m 3 . The maximum binding force of the straw forming system is 1000-2000N, and the power is 5-10kW.

[0041] 2. γ-ray irradiation treatment: using 60 Co-γ ray irradiates the straw block once, the source capacity of the irradiation box is 6 million curies, the irradiation dose is 400 kGy, the dose rate is 10 kGy / h, and the radiation source intensity is 2.22×10 16 Bq (7.4×10 15 ~2.22×10 16 Bq can be). During one irradiation treatment, the straw block is divided into upper a...

Embodiment 2

[0057] a kind of like figure 1 The method for producing fuel ethanol based on irradiation pretreatment stalks of the present invention comprises the following steps:

[0058] 1. Raw material preparation: After collecting the naturally dried corn stalks in the farmland, they are bundled and formed into straw blocks with consistent specifications by a straw forming system (for example, pressed by a hydraulic baler). The volume size of the straw blocks is 1000mm×600mm ×600mm (length×width×height), density is 400kg / m 3 . The maximum binding force of the straw forming system is 1000-2000N, and the power is 5-10kW.

[0059] 2. γ-ray irradiation treatment: using 60 Co-γ ray was used to irradiate the straw block once. The source capacity of the irradiation box was 8 million curies, the irradiation dose was 300 kGy, the dose rate was 15 kGy / h, and the intensity of the radioactive source was 2.22×10 16 Bq. During one irradiation treatment, the straw block is divided into upper and ...

Embodiment 3

[0072] a kind of like figure 1 The method for producing fuel ethanol based on irradiation pretreatment stalks of the present invention comprises the following steps:

[0073] 1. Raw material preparation: After collecting the rapeseed straws that have been naturally dried in the farmland, they are bundled and formed into straw blocks with consistent specifications by a straw forming system (for example, pressed by a hydraulic baler). The volume size of the straw blocks is 1000mm×600mm ×550mm (length × width × height), density is 350kg / m 3 . The maximum binding force of the straw forming system is 1000-2000N, and the power is 5-10kW.

[0074] 2. γ-ray irradiation treatment: using 60 Co-γ ray irradiates the straw block once, the source capacity of the irradiation box is 10 million curies, the irradiation dose is 200 kGy, the dose rate is 15 kGy / h, and the intensity of the radioactive source is 2.22×10 16 Bq. During one irradiation treatment, the straw block is divided into upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com