Saccharomyces cerevisiae strain and application thereof

A technology for fermentation of Saccharomyces cerevisiae and yeast, applied in the field of microorganisms, can solve the problems of unstable bread quality and flavor, unstable and unstable yeast, etc., and achieve the effects of unique flavor, fast fermentation speed and high fermentation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

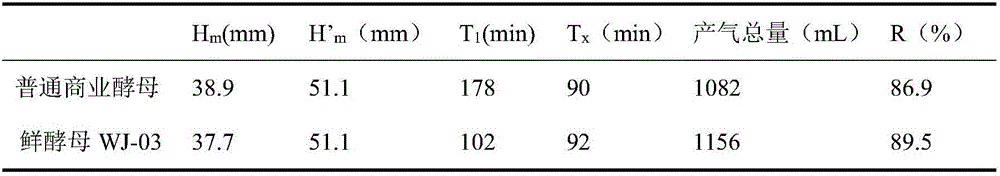

[0032] Embodiment 2 Saccharomyces cerevisiae WJ-03 prepares dough

[0033] (1) Preparation of Saccharomyces cerevisiae suspension

[0034] Saccharomyces cerevisiae WJ-03 was inoculated into 400 mL of YPD liquid medium with a 1% inoculum size, activated at 220 rpm for 14 hours at 30°C, and then inoculated into the YPD liquid medium with a 4% (volume ratio) inoculum amount, and incubated at 30°C , shake culture at 220rpm for 22h to late logarithmic phase, and obtain a concentration of 4×10 8 cfu / mL bacterial suspension;

[0035] (2) Preparation of yeast dough

[0036] The bacterial suspension obtained in step (1) was centrifuged at 8000 g for 10 min, and the bacterial cells were washed 2 to 3 times with sterile physiological saline to obtain fresh yeast.

[0037] 240g of high-gluten flour, 9.6g of fresh yeast, 30g of sugar, 3g of salt, and 135g of water were stirred into a dough, and 15g of shortening was added and stirred at a speed of 280rpm for 3 minutes until the gluten n...

Embodiment 3

[0043] The preparation of embodiment 3 Saccharomyces cerevisiae WJ-03 starter

[0044] Saccharomyces cerevisiae WJ-03 was inoculated into 200 mL of YPD liquid medium with a 1% inoculum size, activated at 30°C at 220rpm for 14 hours, and then inoculated into a YPD liquid medium with a 4% (volume ratio) inoculum size at 30°C , shake culture at 220rpm for 22h to late logarithmic phase, and obtain a concentration of 4×10 8 cfu / mL bacterial suspension; centrifuge at 8000g for 10min, wash the bacteria 2-3 times with sterile normal saline, concentrate in 40mL sterile normal saline, add 20mL of lyoprotectant solution (containing trehalose 80g / L, VC15g / L, xylitol 150g / L, skimmed milk powder 200g / L), mix evenly, pre-freeze at -80°C for 12 hours, and dry for 46~100mt under the conditions of cold trap temperature -45°C~-55°C and vacuum degree of 100~150mt 52h, the yeast starter was obtained. The content of Saccharomyces cerevisiae WJ-03 is 1~2×10 10 cfu / g

Embodiment 4

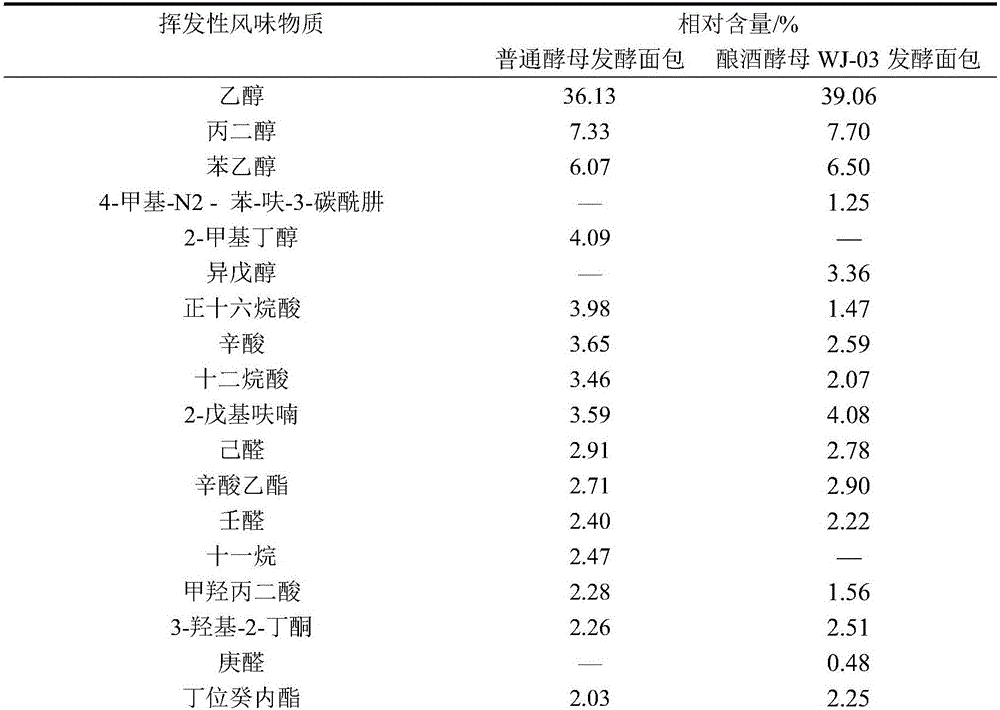

[0045] The preparation of embodiment 4 Saccharomyces cerevisiae WJ-03 fermented bread

[0046]240g of high-gluten flour, 24g of yeast starter, 30g of sugar, 3g of salt, 135g of water and stir to form a dough, add 15g of shortening and stir for 3 minutes at a speed of 280rpm until the gluten network structure is formed, stir slowly for 1min at a speed of 140rpm, cover at room temperature The membrane was allowed to stand for 10 min.

[0047] Divide the above dough into 90g each, and shape into a round shape. Proof in a proofing box (38°C, relative humidity 85%) for 1.5 hours, put the proofed dough in an oven (upper heat 170°C, lower heat 210°C) and bake for 25 minutes.

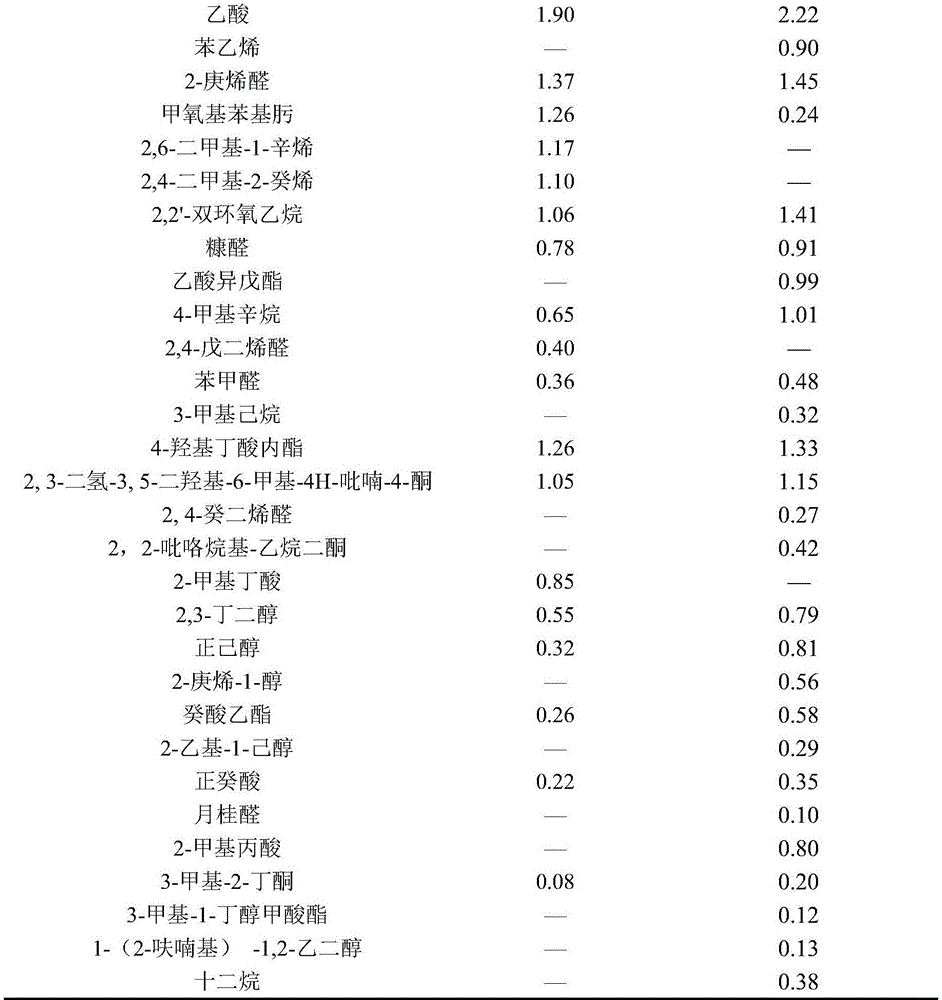

[0048] Plain sourdough bread was prepared in the same manner as above. The volatile flavor components of the two breads were analyzed by solid-phase microextraction-gas chromatography-mass spectrometry (SPME-GC-MS), and the results are shown in Table 2.

[0049] Table 2 GC-MS analysis results of volatile fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com