Low GI hulless oat premix powder without adding flour and preparation method thereof

A technology of ready-mixed flour and buckwheat flour, which is applied in the field of food processing, can solve the problems of high professional requirements for making bread, increase the difficulty of bread, and not buckwheat bread, etc., improve physical and chemical properties and sensory properties, and increase elasticity and strength , Reduce the effect of difficulty and professionalism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 10% water to naked oat flour for wetting, then add 1 part of TG enzyme for ultra-high pressure treatment, the treatment conditions are pressure 300Mpa, time 10min, and then carry out radio frequency modification and drying integrated treatment, radio frequency treatment condition is power 6kW , frequency 27.12MHz, time 30s.

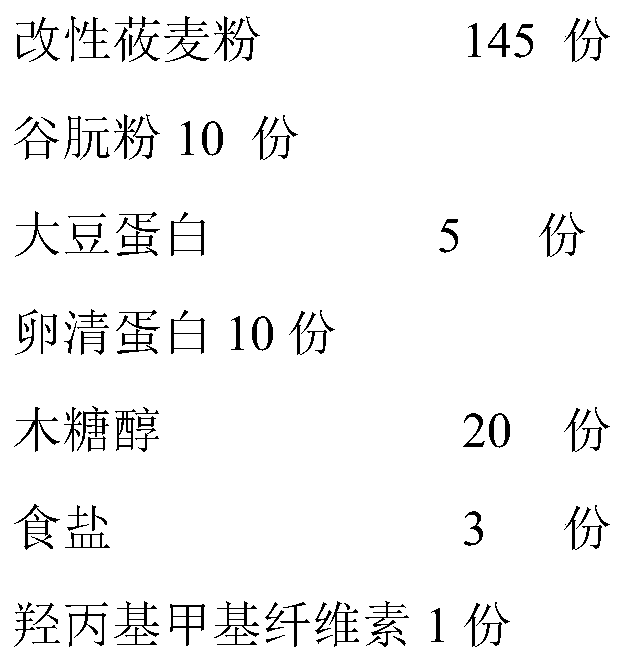

[0039]

[0040]

[0041] Mix and stir the above raw materials evenly to obtain naked oat premix powder according to the present invention.

[0042] Apply the above oat premix powder to make oat noodle bread, and develop low GI and high satiety food that can be applied to diabetic and obese people. The steps are as follows:

[0043] (1) Take 120 parts of water and 18 parts of butter at 38°C and put them into the bucket of the bread machine, add 3 parts of low-sugar and high-activity yeast into the ready-mixed naked oats prepared according to the weight of the above formula, and mix well, then put It is transferred into the bread bucket; ...

Embodiment 2

[0047] Add 15% water to naked oat flour for wetting, then add 1.2 parts of TG enzyme for ultra-high pressure treatment, the treatment conditions are pressure 400Mpa, time 5min, and then carry out radio frequency modification and drying integrated treatment, radio frequency treatment condition is power 10kW , frequency 27.12MHz, time 10s.

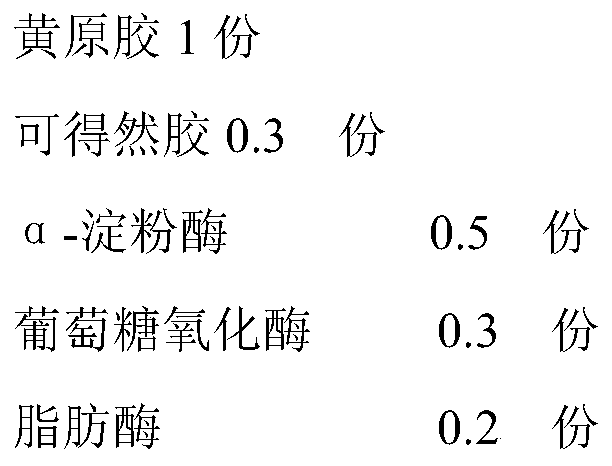

[0048]

[0049] Mix and stir the above raw materials evenly to obtain naked oat premix powder according to the present invention.

[0050] Use the above oat premix powder to make oat noodle bread, the steps are as follows:

[0051] (1) Take 130 parts of water and 20 parts of butter at 38°C and put them into the bucket of the bread machine, add 3.5 parts of low-sugar and high-activity yeast into the ready-mixed naked oats prepared according to the weight of the above formula, and mix well, then put It is transferred into the bread bucket;

[0052] (2) Select any mode under the bread mode, moderately burnt color, start the bread machine, ...

Embodiment 3

[0055] Add 20% water to naked oat flour for wetting, then add 1.4 parts of TG enzyme for ultra-high pressure treatment, the treatment conditions are pressure 500Mpa, time 5min, and then carry out radio frequency modification and drying integrated treatment, radio frequency treatment condition is power 10kW , frequency 27.12MHz, time 20s.

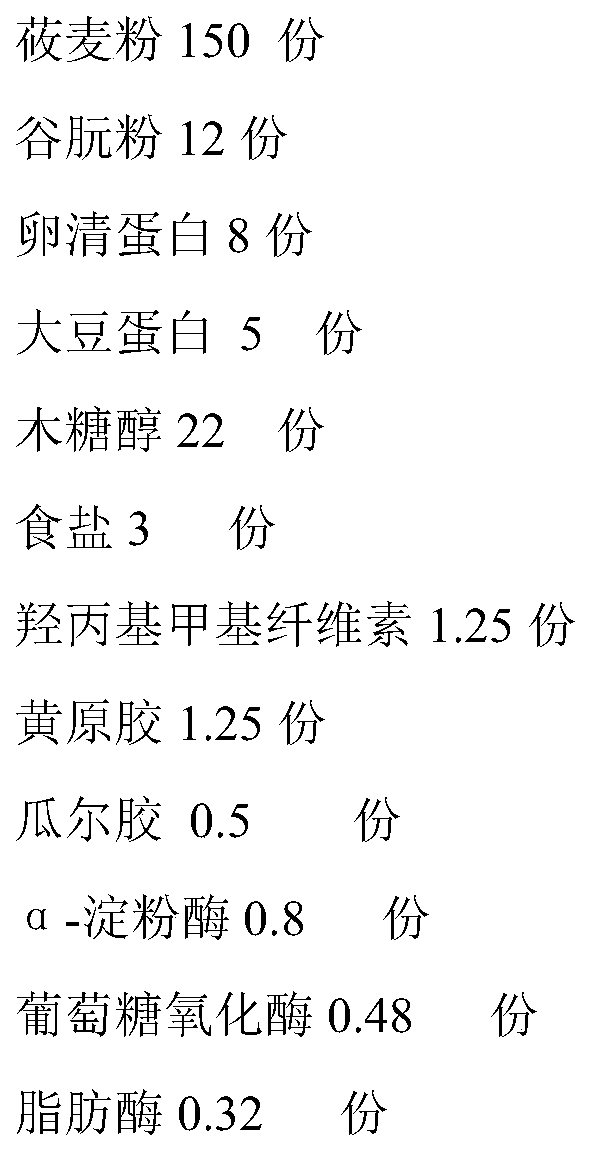

[0056]

[0057] Mix and stir the above raw materials evenly to obtain naked oat premix powder according to the present invention.

[0058] Use the above oat premix powder to make oat noodle bread, the steps are as follows:

[0059] (1) Take 130 parts of water and 20 parts of butter at 38°C and put them into the bucket of the bread machine, add 3.5 parts of low-sugar and high-activity yeast into the ready-mixed naked oats prepared according to the weight of the above formula, and mix well, then put Transfer it to a bread pan.

[0060] (2) Select the self-programming mode, set the dough for 8 minutes at a time, stir until there is no dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com