Method for preparing environment-friendly plastics for manufacturing biomacromolecular carriers and biological utensils

A biological macromolecule and biological technology, which is applied in the field of green plastic preparation for the manufacture of biological macromolecular carrier biological vessels, can solve the problems of unsuitability for large-scale production, low production efficiency, complicated process, etc., and achieve saving of production costs and application range, Increased productivity and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A green plastic preparation method for manufacturing biological macromolecule carriers and biological vessels, the specific steps are as follows: a: Add low molecular weight polylactic acid to high molecular weight polylactic acid and blend uniformly to obtain mixture A, wherein the low molecular weight polylactic acid in step a Lactic acid and high-molecular-weight polylactic acid are about 1:20, and then made into highly flexible polylactic acid, because when polylactic acid melts at high temperature, its cross-linking bonds open and combine with nano-scale calcium phosphate to form macromolecules. This process belongs to thermophysical The chemical reaction can be completed in only 15 minutes when it is melted, and there is no need for more complicated chemical modification such as grafting reaction. It only needs to be heated and stirred to melt and mix evenly, so the quality and performance are stable and controllable, and it is easy to operate;

[0034] b: Heating ...

Embodiment 2

[0052] A green plastic preparation method for manufacturing biological macromolecule carriers and biological vessels, the specific steps are as follows:

[0053] a: Add low-molecular-weight polylactic acid to high-molecular-weight polylactic acid and blend uniformly to obtain mixture A, wherein the ratio of low-molecular-weight polylactic acid and high-molecular-weight polylactic acid in step a is about 1:20, and then high-flexibility polylactic acid is produced;

[0054] b: Heat the mixture A and add nano-calcium carbonate to stir and blend evenly, the weight ratio of nano-calcium phosphate to mixture A is 0.1;

[0055] c: extrusion granulation to generate green plastic masterbatch.

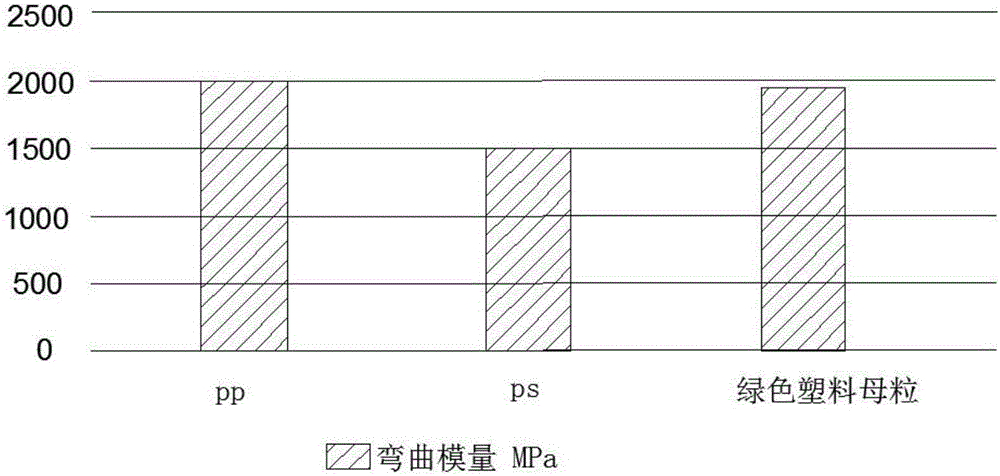

[0056] The green plastic masterbatch has high plasticity and low glass transition temperature; its bending strength is 68MPa, which fully meets the requirements of modern medical devices; and it can be blown and injected at low temperature and high pressure, and can be produced on a large scale; b...

Embodiment 3

[0072] A kind of green plastic preparation method that is used to manufacture biological container, concrete steps are as follows:

[0073] a: Add low-molecular-weight polylactic acid to high-molecular-weight polylactic acid and blend uniformly to obtain mixture A, wherein the ratio of low-molecular-weight polylactic acid and high-molecular-weight polylactic acid in step a is about 1:20, and then high-flexibility polylactic acid is produced;

[0074] b: Heat the mixture A and add nano-calcium carbonate to stir and blend evenly, the weight ratio of nano-calcium phosphate to mixture A is 0.3;

[0075] c: extrusion granulation to generate green plastic masterbatch.

[0076] The green plastic masterbatch has high plasticity and low glass transition temperature; its bending strength is 68MPa, which fully meets the requirements of modern medical devices; and it can be blown and injected at low temperature and high pressure, and can be produced on a large scale; because the modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com